GB-6

JACOBSEN AR3

NARROW WIDTH OF CUT FIELD KIT

FITTING INSTRUCTIONS

3

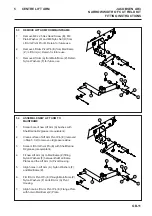

PREPARATION

3.1

PREPARATION

CAUTION: Read the tractor’s manual and

become familiar with the tractor, the controls and

proper use of the equipment.

Stay alert for potential hazards and follow all

safety precautions. Read all instructions

completely and make sure you understand them

before proceeding with the assembly

1.

Park the tractor on a flat and level surface, fully

lower the implements to the ground, engage

parking brake, stop the engine and remove key

from ignition switch.

a. Wait for all movement to stop before

making any adjustments or

modifications.

b. Take this opportunity to thoroughly

inspect the equipment and perform other

maintenance.

The “Right” and “Left”, “Front” and “Rear” of the

machine are referenced from the operator’s right and

left when seated in the operator’s seat facing the

direction of forward travel.

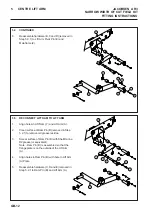

3.2

IMPORTANT NOTE

1.

It is not necessary to break any hydraulic

connections when fitting this Field Kit.

2.

This modification will reduce the protential for

feathering on side slopes. However it also

reduces the width of cut from 1.82m (72in) to

1.7m (67in).