5/7

P 5 4

1~10

1

Presser foot lifting electromagnet per cycle closing time (ms)

P 5 6

0/1

1

Run to up needle position after Power on

:

0: no action 1: action

P 5 7

0~600

0

Presser foot lifting electromagnet protection time 100ms

P 6 0

200~5000

3000

The maximum speed of constant sewing (Automatic test speed)

P 6 2

0/1/2/3

0

Special mode:

0: normal Mode

1: simply sewing mode

2: motor initial angle measurement (Do not remove the belt)

3: Automatically setting the pulley ratio by the CPU. (Synchronizer is necessary and the belt

not removed)

4: automatic test modle 1 (It has needle stop position of automatic test, running and stopping

5S)

P 6 6

2

2

The 2 input function definitions (Lockstitch safety switch function set)

P 6 8

0~5000

3500

The maximum speed limit of the machine head

P 7 1

0~50

0

Slow release lifter level adjustment, the smaller values and the faster quickly (OC open time)

P 7 6

1~500

70

Back sewing electromagnet full output time ms

P 7 8

10~359

120

Start angle

P 7 9

11~359

318

End angle

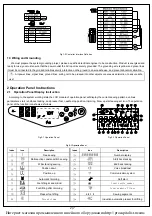

3.2 Monitor mode

No.

Description

No.

Description

0 1 0

Count needle number

0 2 4

Machine angle

0 1 1

Counter for sewing pieces

0 2 5

The sampling voltage of pedal

0 1 2

The head of really speed

0 2 6

The ratio between motor and machine

0 1 3

State of encoder

0 2 7

The total used time(hours) of motor

0 2 0

DC voltage

0 2 8

The sampling voltage of interaction

0 2 1

Machine speed

0 2 9

Software version

0 2 2

The phase current

0 3 0 - 0 3 7

The history record of error codes

0 2 3

Initial electrical angle

3.3 The warning message

Alarm code

Description

Corrective

Count over for stitches

The counter reaches the limit. Press

key to reset the counter.

Count over for sewing pieces

The counter reaches the limit. Press

key to reset the counter.

Power is off

Please wait for 30 seconds, then turn on the power switch

Safety switch alarm

Adjust the machine to the correct position.

Интернет магазин промышленного швейного оборудования http://procapitalist.ru/sms