Approved Installation Manual for the Experimental

Report No 104

EDM-350

Page 13 of 46 Rev A

Engine Data Management System Date 7-10-2021

10.1

R

ADIAL

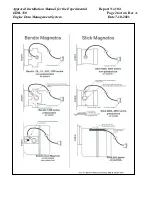

Engine EGT

Radial engine exhaust, require a larger EGT clamp (supplied) to fit the 2.5 inch exhaust pipe. The EGT probe is installed in the

same fashion as a Lycoming or Continental engine and should be placed between the exhaust pipe flange and the accumulator at

a distance of 2 to 3 inches from the engine exhaust flange. Refer to the engine manufactures recommended location. Do not

route the EGT/CHT harness in with the ignition harness. Do not extend the yellow thermocouple leads with copper wire.

10.2

Turbine Inlet Temperature (TIT) Probe Installation (optional)

Use the J1 connector harness 790200 and insert the yellow wire into the connector pin 16 and the red wire into pin

17. The standard TIT probe PN M111-T with a #48 clamp is placed in the exhaust stack accumulator to a maximum

depth of 1/2 inch and approximately 4 inches from the turbine inlet if possible, on the waste-gate side of the turbine.

10.3

TIT for second Turbine Inlet Temperature

Use the J1 connector harness 790200 and insert the yellow wire into the connector pin 18 and the red wire into pin

19. The standard JPI TIT probe P/N M-111-T with a special clamp is placed in the exhaust stack accumulator to a

maximum

depth of 1/2 inch and approximately four inches from the Turbine inlet if possible, on the waste gate side

of the turbine.

10.4

Using an existing TIT Probe

An existing installed TIT probe (K-calibration) is compatible with the JPI EDM-350 System. Connect the JPI wire

marked TIT in parallel with the existing probe noting color polarity. Replacement probes should be purchased per

part number from the aircraft manufacturer.

If you choose to use only the EDM-350 TIT display you may remove the factory installed TIT indicator and leave the

TIT probe installed. Connect the JPI wire marked TIT directly to the probe noting color polarity. The TIT probe should

now have only the JPI leads attached to it. No calibration of the EDM-350 is necessary.

11.

Cylinder Head Temperature (CHT) Probe Installation

Use the J2 connector harness 700700 or 700702 labeled C1 through C4 or C6. The JPI probe is a bayonet probe

P/N 5050 that has a captive 3/8-24 boss that is screwed into the head of each cylinder.

12.

Radial Engine CHT (spark plug gasket)

Cylinder head temperatures are measured with a spark plug gasket type probe placed under the rear sparkplugs.

The spark plug gasket probe, P/N M-113, replaces the standard copper spark plug gasket on one spark plug. The

probe is placed on the rear plug for a cleaner installation and less chance of chaffing the thermocouple wiring. After

many removals the probe may be annealed for re-use. Heat to 1100

o

F and quench in water.

13.

Outside Air Temperature (OAT) Probe Installation

Use the J1 connector harness 790200 labeled OAT. All wiring must be type K thermocouple wire. Do not splice

ordinary copper wire in any temperature probe circuits.

Install the OAT probe, PN 400510 in the airframe manufacturer’s recommended location. If this information is not

available, place the OAT probe in clean airflow such as in a cabin air scoop or below the underside of the wing away

from engine heat or exhaust. In this case it is recommended that the installation be done similar to the antenna

installation instructions of AC 43.13-2b

Acceptable Methods, Techniques and Practices

.

The outside aluminum shield tube is used to both hold the probe in place and shield it from radiated heat from the

sun. The OAT option is displayed as an independent digital temperature bar graph such as "75.”