P

RODUCT INFORMATION

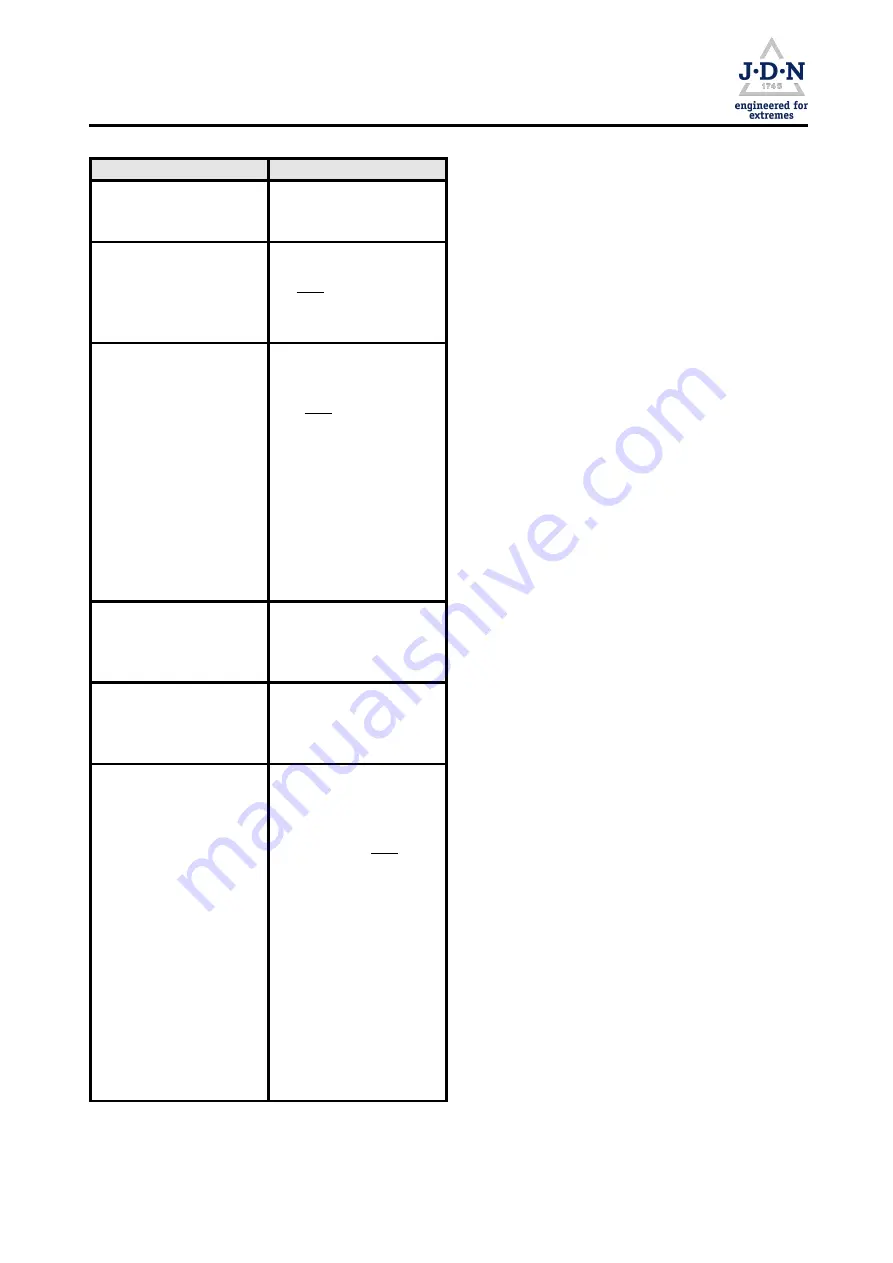

Application area

Operating material

Motor lubrication

JDN high performance

grease, item no. 11904

(250ml)

Engine lubrication for

operation with oiler

Air lubricator “D”, kine-

matic viscosity about

30

mm

2

s

(cSt) at 40

◦

C,

possibly with anti-icing

agent

Chain lubrication

Chain oil or vehi-

cle motor oil, kine-

matic viscosity about

150

mm

2

s

(cSt) at 40

◦

C,

or special lubricant

from J.D. Neuhaus.

In areas with extreme

corrosion potential,

such as offshore, a

lubricant with a particu-

larly powerful corrosion

protection is to be

used.

Motor corrosion pro-

tection (not applicable

if using the JDN high

performance grease)

Non-gumming preser-

vative oil with corre-

sponding effective

duration

Engine cleaning (not

applicable if using the

JDN high performance

grease)

Pure petroleum

Lubrication for bearings

and gearbox (also for

open gears)

Lithium-saponified

grease, worked pen-

etration 265-295

(0,1mm), base oil

viscosity: 190

mm

2

s

(cSt)

at 40

◦

C, dropping point:

180

◦

C,

Application temper-

atures: -20

◦

C to +

120

◦

C,

Designation according

to DIN 51825: KP2K-

20, active ingredients:

EP additives (to reduce

wear) and ageing pro-

tection; water-resistant

and anti-corrosive

3.10. Explosion protection

The basis for the following information is an expert

statement by DMT Gas & Fire Division regarding

the use of JDN hoists, trolleys and cranes in po-

tentially explosive areas based on the European

directive 94/9/EC (“ATEX 100a”). DMT is accred-

ited for the testing devices and protective systems

for proper use in potentially explosive areas.

Load chain

To ensure the required earthing,

badly rusted chains may no longer be used in

zones 1 and 21 as well as in devices of category

M2. For, depending on the degree of corrosion,

the conductivity of the chain may deteriorate so

that it is no longer sufficient.

Hoses

Hoses in zone 1 must have a sufficiently

low surface resistance of less than

10

9

Ω

in order to

avoid electrostatic ignition hazards. Otherwise (at

>

10

9

Ω

) the hoses for explosion groups I, IIA and

IIB must be

≤

∅

30

mm

and for explosion group IIC

≤

∅

20

mm

or they must have the evidence that

they cannot be dangerously loaded.

Materials for friction and impact hazards

Fric-

tion and impacts may cause individual sparks that

may cause a risk of ignition for gases of the ex-

plosion group IIC, hydrogen sulphide or ethylene

oxide as well as for light metal or other impact-

sensitive dusts. Therefore, spark formation caused

by mechanical influences must be prevented here.

The chain and load are always to be moved in

such a way that sliding and/or frictional contact

with other systems and components is excluded.

If circumstances do not permit this, it is necessary

to ensure an absence of explosive atmospheres

during operation.

Impacts between special material pairings result

in an increased ignition hazard. This does not ap-

ply to corrosion-resistant steel or cast iron against

aluminium, magnesium or corresponding alloys.

This especially applies in the presence of rust or

rust film. Rust (also rust film) may form at the fric-

tion points, especially on the chain and on the load

hook. The following applies for all zones: For the

intended use of your product, it is to be ensured

that no rust is present at the aforementioned fric-

tion points and that material combinations from the

aforementioned light metals and steel (exceptions

Page

22

of 64

Doc.-No.: VA049318-10-OM-EN-0319-64-2