Intel® Server System M70KLP Family Service Guide

14

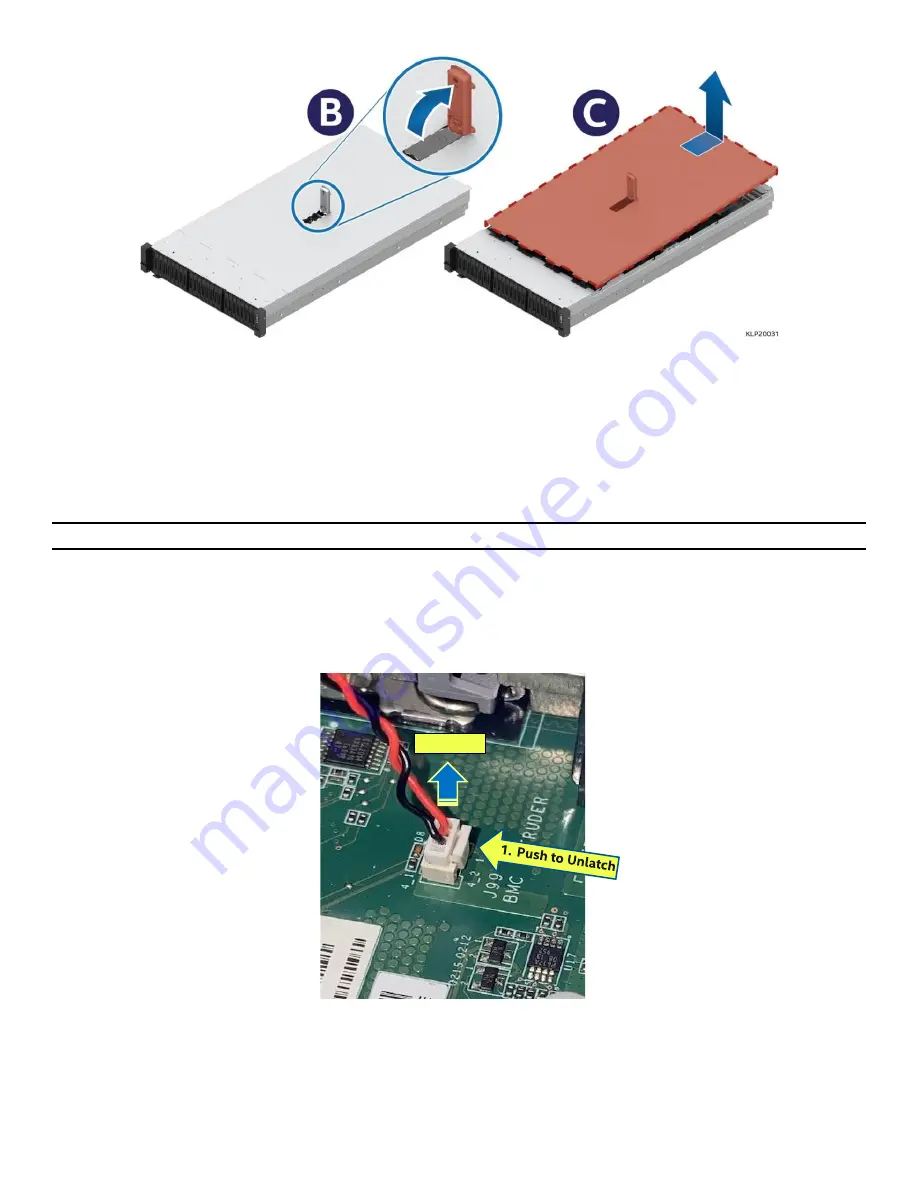

Figure 2. System Top Cover Removal

1.

Using a phillips screw driver, rotate the latch lock ¼ tur

n to the “Unlock” position

(see Letter A).

2.

Lift the latch to its full open position. The top cover will slide back (see Letter B).

3.

Lift the back edge of the top cover, then slide the top cover back and away from the chassis

(see Letter C).

2.1.2

Air Duct Removal

Note:

Instructions will be identical regardless of air duct type installed (Standard or Low Profile)

The air duct is held in place using a lock bar that must be removed prior to removing the air duct. Integrated

within the lock bar assembly is a chassis intrusion switch that is cabled to the server board. This cable must

be carefully disconnected from the server board before removing the lock bar.

Figure 3. Chassis Intrusion Switch Cable Connection on Server Board

1.

Located below the back edge of the air duct, unlatch and disconnect the white two-wire chassis

intrusion switch cable from the server board (see

).

•

DO NOT pull on the wires to disconnect the cable

. Doing so may detach the wires from the

connector.

2. Pull-up

Summary of Contents for M70KLP Series

Page 2: ...Intel Server System M70KLP Family Service Guide Blank page...

Page 94: ...Intel Server System M70KLP Family Service Guide 92 1 2 3 4 5 6 1 2 3...

Page 95: ...Intel Server System M70KLP Family Service Guide 93 1 2 3 4 5...

Page 96: ...Intel Server System M70KLP Family Service Guide 94 7 8 9 10 11 12 4 5 6...

Page 97: ...Intel Server System M70KLP Family Service Guide 95 6 7 8 9 10...

Page 106: ...Intel Server System M70KLP Family Service Guide 104 1 2 3 4 5 ESD 6 1 2 3...

Page 107: ...Intel Server System M70KLP Family Service Guide 105 1 2 3 4 5...