http://air.ingersollrand.com

1

OPeRATIOn AnD MAInTenAnCe MAnUAL

GeneRAL InFORMATIOn

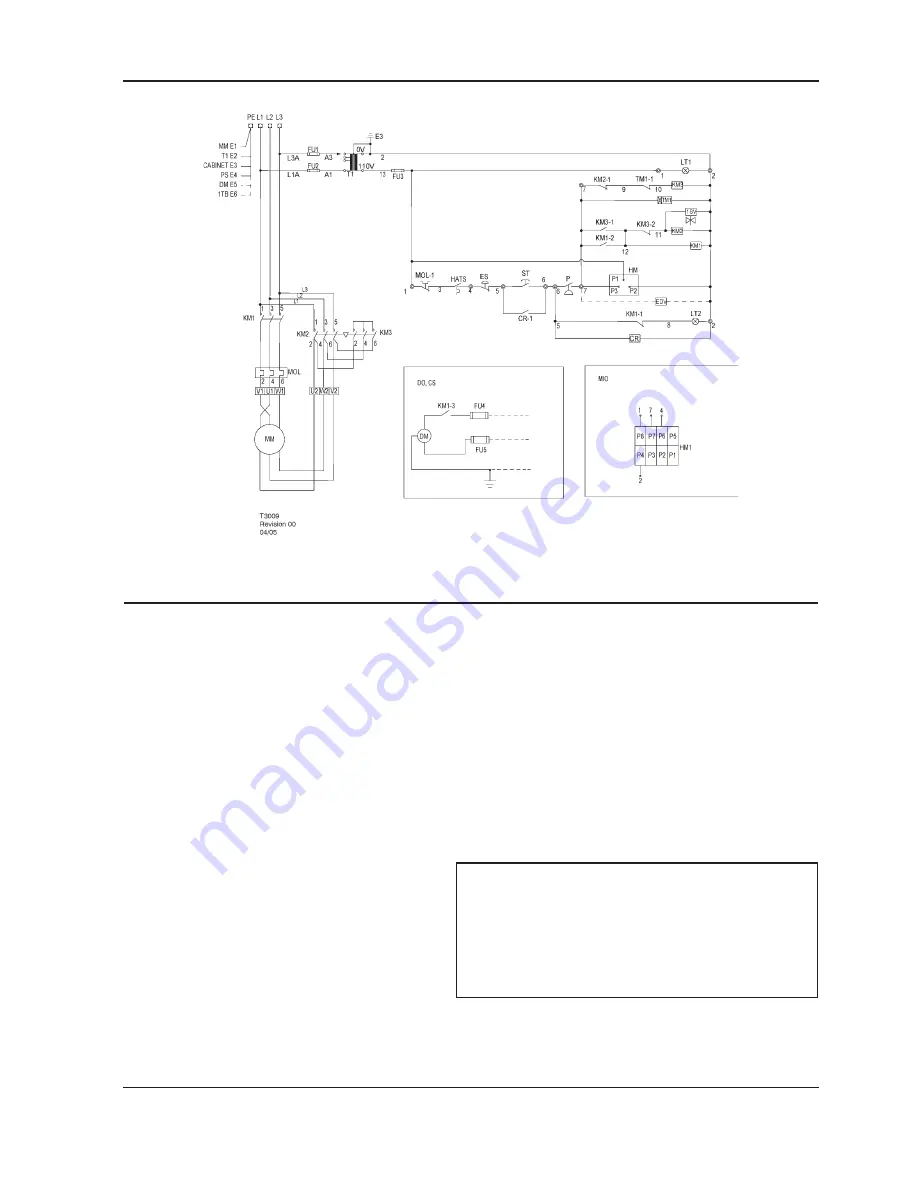

SCHeMATIC, eLeCTRICAL UP5 5–15HP SD 3PH 50Hz

KeY

1SV

Valve, solenoid (nc)

KM2-1,2

Contacts, auxiliary. Delta contactor

CR

Relay, control

KM

Contactor, star

CR-1

Contact, control relay

KM-1,2

Contacts, auxiliary. Star contactor

CS

Customer supplied 20v / 1 / 50hz

LT1

Light, power on indicator (green)

DM

Motor, dryer

LT2

Light, auto restart indicator (white)

DO

Dryer option

MIO

Indicator, maintenance option

EDV

Valve, electric drain

(Instead of standard hourmeter)

HATS

Switch, high air temperature

MOL

Overload, main motor

HM

Hourmeter

MOL-1

Contact, main motor overload

HM1

Indicator, maintenance

ST

Push button, start

MM

Motor, compressor

T1

Transformer, control

P

Switch, pressure

TM1

Relay, delta starting (10sec)

ES

Switch, emergency stop

TM1-1

Relay, delay off, contact

FU1, FU2

Fuse, primary

FU

Fuse, secondary

nOTeS

FU, FU5

Fuse, dryer

1.

(*) Furnished, mounted and wired outside of

control panel, if required by order.

KM1

Contactor, main

2.

Circuit shown in normal position de–energized.

KM-1,2,

Contacts, auxiliary. Main contactor

.

All wiring to be marked in accordance with this

schematic.

KM2

Contactor, delta

.

All wiring to be in accordance with NEC.