MAINTENANCE

WARNING

•

Never perform maintenance on the hoist while it is supporting a load.

•

Before performing maintenance, tag controls:

WARNING - DO NOT OPERATE -

EQUIPMENT BEING REPAIRED.

•

Only allow personnel trained in service and repair of this hoist to perform

maintenance.

•

After performing any maintenance on the hoist, test hoist before returning

hoist to service.

•

Turn off and lockout/tag out electrical disconnect switch before performing

any maintenance.

•

The lower sheave block or hook assembly must be lying on the floor or a

maintenance platform before beginning service.

n

General Maintenance Instructions

NOTICE

•

It is recommend that maintenance work be performed by an Ingersoll Rand

service repair center.

•

If the operator performs maintenance work on an electric chain hoist on his

own account, the type of maintenance performed must be entered together

with the date of performance into the inspection pass.

All maintenance work performed on the hoist must be recorded with the date in the

inspection report.

Alterations to, as well as changes of and supplements to the electric chain hoists

which may impair the safety must be authorized by Ingersoll Rand in advance.

Constructional alterations to the chain hoists not authorized by the Ingersoll

Rand lead to an exclusion of the manufacturer’s liability in case of damage.

Material warranty claims will only be recognized if solely genuine spare parts by

Ingersoll Rand have been employed.

We explicitly wish to point out that original parts and accessories not supplied on

our behalf cannot be inspected or released by us.

Proper use, inspections and maintenance increase the life and usefulness of your

Ingersoll Rand equipment. During assembly, lubricate gears, nuts, capscrews and

all machined threads with applicable lubricants. Use of antiseize compound and/or

thread lubricant on capscrew and nut threaded areas will help to prevent corrosion

and allows for ease of disassembly of components.

It is recommended that all maintenance work on the hoist be performed on a bench

in a clean dust free work area. During the process of disassembling the hoist, observe

the following:

1. Turn off and lockout/tag out electrical disconnect switch before performing any

maintenance. Disconnect electrical cable from hoist.

2. Never disassemble the hoist any further than is necessary to accomplish the

needed repair. A good part can be damaged during the course of disassembly.

3. Never use excessive force when removing parts. Tapping gently around the

perimeter of a cover or housing with a soft hammer, for example, is sufficient to

break the seal.

4. Do not heat a part with a flame to free it for removal, unless the part being heated

is already worn or damaged beyond repair and no additional damage will occur

to other parts.

NOTICE

•

In general, the hoist is designed to permit easy disassembly and assembly.

The use of heat or excessive force should not be required.

5. Keep the work area clean to prevent dirt and other foreign matter from getting

into bearings and other moving parts.

6. All seals and O-Rings should be discarded once they have been removed. New

seals and O-Rings should be used when assembling the hoist.

7. When grasping a part in a vise, always use leather or copper covered vice jaws

to protect the surface of the part and help prevent distortion. This is particularly

true of threaded members, machined surfaces and housings.

8. Do not remove any part which is press fit in or on a subassembly unless the

removal of the part is necessary for repairs or replacement.

9. To avoid damaging bearings during hoist assembly or disassembly always tap

or press on the bearing inner race for shaft fit bearings or the outer race for bore

fit bearings. When removing bearings from housings, drive out the bearing with

a sleeve slightly smaller than the outside diameter of the bearing. The end of the

sleeve or pipe that is used to contact the bearing must be square. Protect

bearings from dirt by keeping them wrapped in clean cloths.

10. If repair work can only be conducted above body height, suitable working

platforms or ladders should be made available.

11. Work on electrical equipment or machinery may only be conducted by licensed

electricians or persons under the supervision and guidance of licensed

electricians, in accordance with all appropriate electrical codes and regulations.

WARNING

•

All new, altered or modified equipment should be inspected and tested by

personnel trained in safety, operation and maintenance of this equipment

to ensure safe operation at rated specifications before placing equipment

in service.

Inspection procedures for hoist in regular service are divided into two general

classifications based upon the intervals at which inspection should be performed.

The intervals in turn are dependent upon the nature of the critical components of

the hoist and the degree of their exposure to wear, deterioration or malfunction.

The two general classifications are herein designed as frequent and periodic. The

inspection intervals recommended in this manual are based on intermittent

operation of the hoist; that is, eight hours per day, and five days a week, in an

environment relatively free of dust moisture and corrosive fumes. If the hoist is

operated with a greater run time per shift or more than eight hours per day the

inspection interval must be reduced. Refer to ASME B30.16 for specific time period.

Careful inspection on a regular basis will reveal potentially dangerous conditions

while still in the early stages, allowing corrective action to be taken before the

condition becomes dangerous.

Deficiencies revealed through inspection, or noted during operation, must be

reported to designated personnel trained in safety, operation and maintenance of

this equipment. A determination as to whether a condition constitutes a safety

hazard must be decided, and the correction of noted safety hazards accomplished

and documented by written report before placing the equipment in service.

n

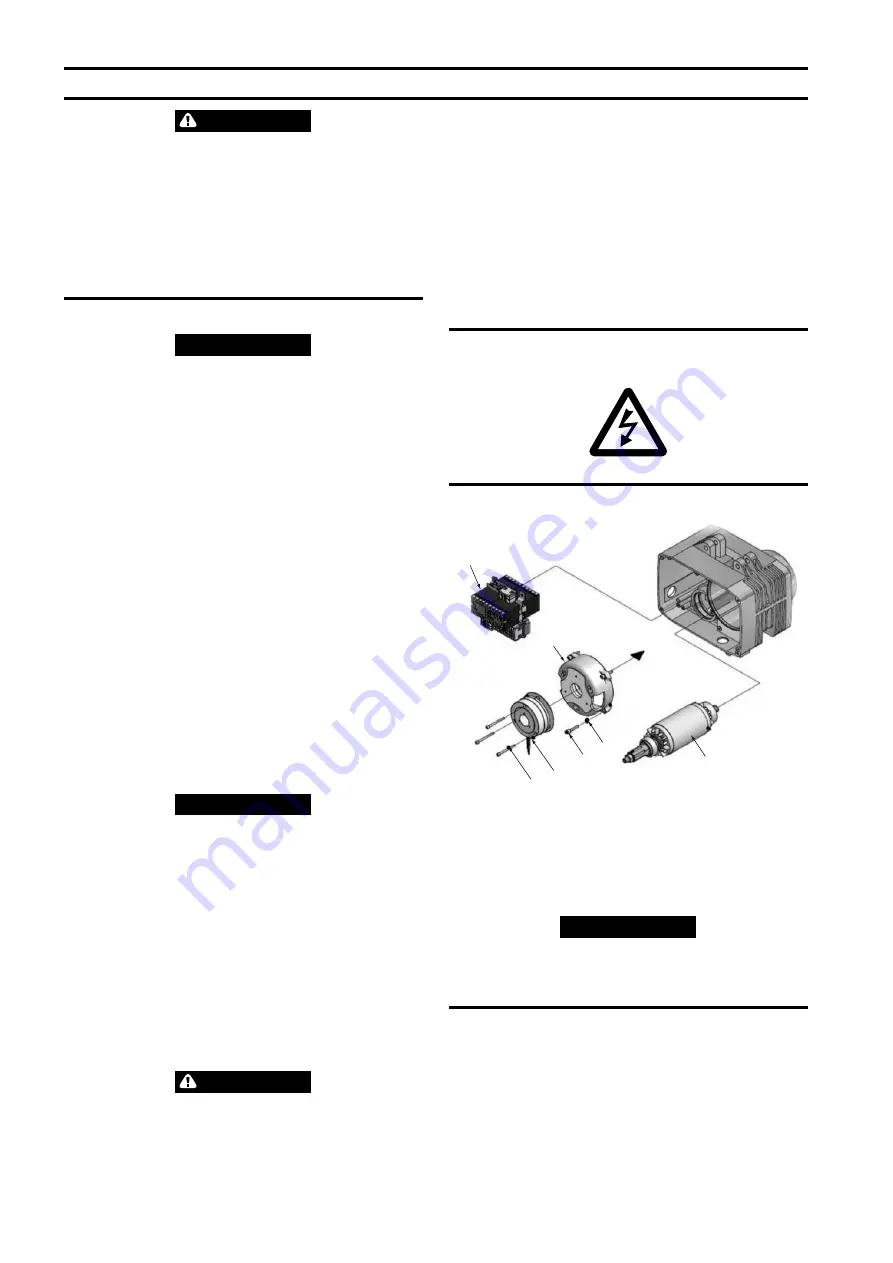

Cover Removal

Electrical side is indicated by Symbol.

(Dwg. MHP3349)

n

Brake System (AC Brake)

4

5

7

6

3

2

1

(Dwg. MHP3332)

n

Assembly

1. Install the rotor shaft (3) into the housing.

2. Install the motor cover (2) into the housing. (Preheat the Cover if necessary).

3. Insert the spring washer (6), and tighten the allen screw (7) and torque to 6-10

Nm.

4. Place the brake assembly on the motor cover.

5. Insert allen screw (5) and tighten to torque 3-10 Nm.

NOTICE

•

Play Check the brake assembly and adjust if necessary.

6. Fit the adjusting screw (1).

7. Install the control assembly (4). Refer to “WIRING DIAGRAM” on page 8 on

pages 9 and 10.

n

Brake System (DC Brake)

In the power free mode, the brake must be able to hold the nominal load without

any problems. It has been operationally adjusted before delivery.

6

Form 16586737 Edition 4

Summary of Contents for QCH100

Page 10: ...www ingersollrandproducts com...