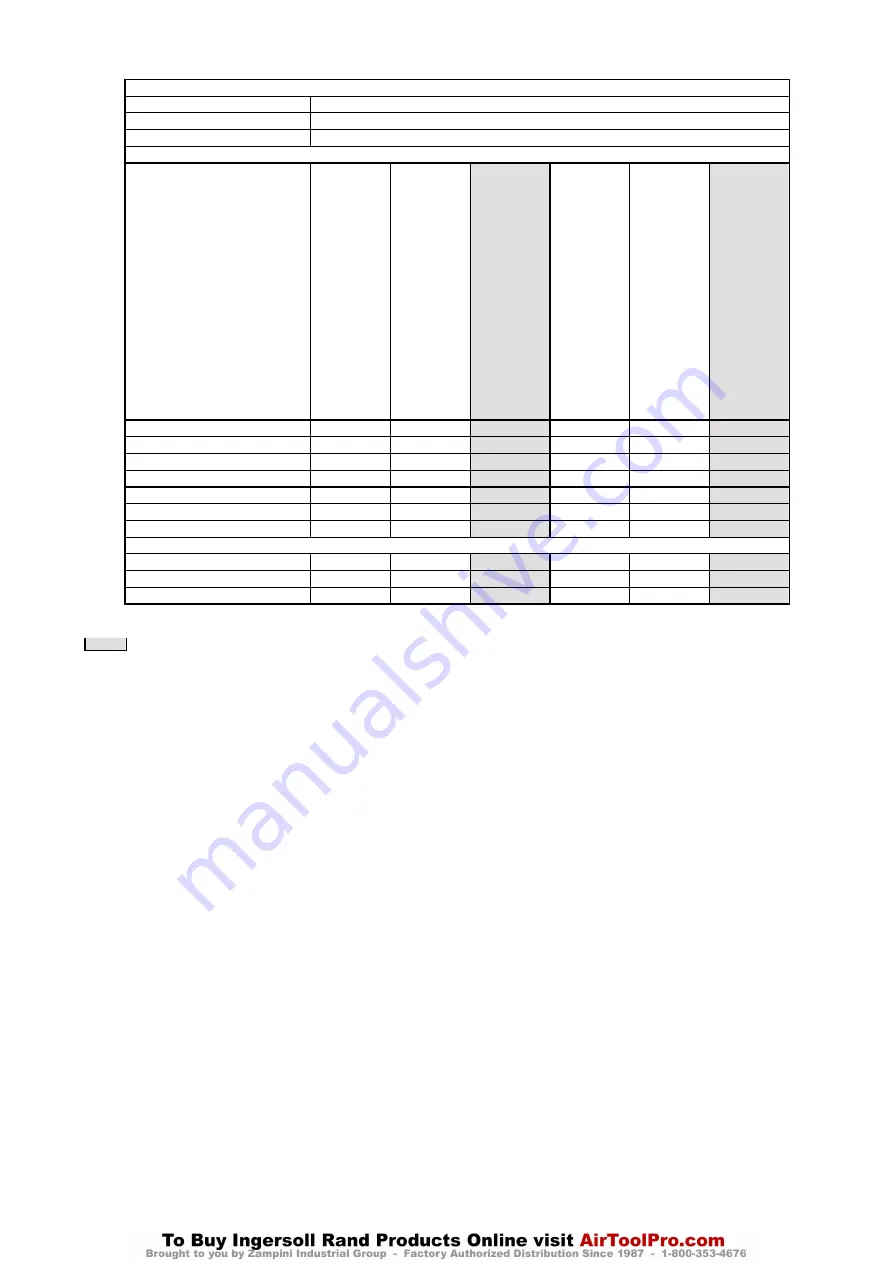

Table 3: Decoking Winch Maintenance Interval Chart

The following work can be completed by owner maintenance personnel

System Air Filter

Inspect system air filter every 30 days or 100 hours

Grease Fittings

Lubricate grease fittings every 90 days or 250 hours

Gearbox Oil Level

Check oil level in gearbox every 90 days or 250 hours

It is recommended that the following work be completed by a trained Ingersoll Rand trained service technician.

Standard Components

1 year or

1,000 hrs

2 years or

2,000 hrs

3 years or

3,000 hrs

4 years or

4,000 hrs

5 years or

5,000 hrs

6 years or

6,000 hrs

Inspect Motor

X

X

Inspect Manual Band Brake

X

X

X

X

X

X

Inspect Disc Brake

X

X

Inspect Gearbox

X

X

Replace Winch Anchor Bolts

X

X

Rebuild Control Valve

X

X

Inspect Drum, Housings and Main Frames

X

X

X

X

X

X

Optional Components

Emergency Shut-Off Valve

X

X

X

X

X

X

Limit Switches

X

X

X

X

X

X

Automatic Band Brake *

X

X

X

X

X

X

*

Do not disassemble band brake air cylinder unless brake operation or visual inspection indicates a requirement.

NOTE: Hours are for actual winch drum rotation.

Recommend complete general overhaul.

Form MHD56375 Edition 2

3

Summary of Contents for FH5i-DCOKER

Page 11: ...Form MHD56375 Edition 2 11...

Page 12: ...www ingersollrandproducts com...