2.

Rigging:

-

Correct size wire rope is being used. 10 mm minimum

-

Wire rope take-off angle is within design limits

3.

Visual Integrity:

-

All Components - Inspect for wear, damage, distortion, deformation and

cleanliness. If external evidence indicates damage, contact

Ingersoll Rand

Service Technician to disassemble as required to conduct a detailed

inspection

-

No part of the winch has been welded onto

-

Fasteners - Check external retainer rings, split pins, capscrews, nuts and other

fasteners on winch, including mounting bolts

-

Drum and Sheaves - Check for cracks, wear or damage

-

Press Roller - Inspect rollers for wear and grooves. Ensure rollers freely rotate.

Replace rollers if worn or grooved. Replace bearings if rotation is rough or

stiff

-

Slack Line Detector - Inspect rollers for wear and grooves. Ensure rollers freely

rotate

-

Ensure drum guard is capable of adequately guarding personnel

-

No modifications have been performed on the winch

-

Check motor, gearbox and disc brake for oil leakage

4.

Labeling / Marking:

-

Data (name) plate is attached and legible

-

Warning tags and labels are attached, legible and in correct places on winch

5.

Wire Rope Spooling:

-

A minimum of 3 dead wraps remain on drum in fully paid-out position

-

Proper freeboard is maintained at full haul-in position (minimum 1 inch (26

mm) for 10 mm wire rope)

-

Wire rope is properly lubricated

6.

Operational Checks:

-

Manual Band Brake: Connect auxiliary air supply to emergency brake release

system, disengage manual band brake, lift load a short distance, and depress

emergency brake release valve. Load should begin to drift downward. Apply

manual band brake with emergency brake release valve still depressed. Load

should stop

-

Limit Switches - Operate winch in the haul-in direction until limit switch

engages. Ensure winch stops running in haul-in direction, and operate in

payout. Operate winch in payout direction until limit switch engages. Ensure

winch stops operating in payout direction, and will operate in haul-in

direction

-

Line Speed - Raise and lower (5 ft. min. distance) a 485 lbs (220 kg) load at

first layer to verify line speed. Line speed to be 60 fpm (18 m/min). Line

speed to be recorded after warm-up

n

Winches Not in Regular Use

1. Equipment which has been idle for a period of one month or more, but less than

six months, shall be given an inspection conforming to the requirements of

‘Frequent Inspection’ on page 8 before being placed in service.

2. Equipment which has been idle for a period of over six months shall be given a

complete inspection conforming with requirements of ‘Periodic Inspection’ in

maintenance manual before being placed in service. Refer to Product Maintenance

Information Manual.

3. Standby equipment shall be inspected at least semiannually in accordance with

requirements of ‘Frequent Inspection’ on page 8. In abnormal operating

conditions equipment should be inspected at shorter intervals.

4. All oils must be drained and replaced with new, and all grease cavities shall be

packed to the prescribed limit. Refer to “LUBRICATION” section on page 9.

Product must be operated for at least 15 seconds in both directions with well

lubricated, dry air.

n

Storing The Winch

1. Always store the winch in a no load condition.

2. Wipe off all dirt and water.

3. Oil the wire rope.

4. Place in a dry location.

5. Before returning winch to service, follow instructions for ‘Winches Not In Regular

Use’ in the “INSPECTION” section on page 8.

6.

Mufflers and Breathers.

All mufflers and breathers must be removed and replaced

with threaded plugs to prevent dust and moisture from entering motor and valve

assemblies.

7.

Rotary Limit Switch.

Product equipped with a rotary limit switch must be stored

with the limit switch not activated.

LUBRICATION

To ensure continued satisfactory operation of winch, all points requiring lubrication

must be serviced with correct lubricant at proper time interval as indicated for each

assembly.

Refer to ‘Maintenance Interval’ chart in Product Maintenance Information Manual for

recommended lubrication intervals. Use only those lubricants recommended. Other

lubricants may affect product performance. Approval for use of other lubricants must

be obtained from your

Ingersoll Rand

distributor. Failure to observe this precaution

may result in damage to winch and/or its associated components.

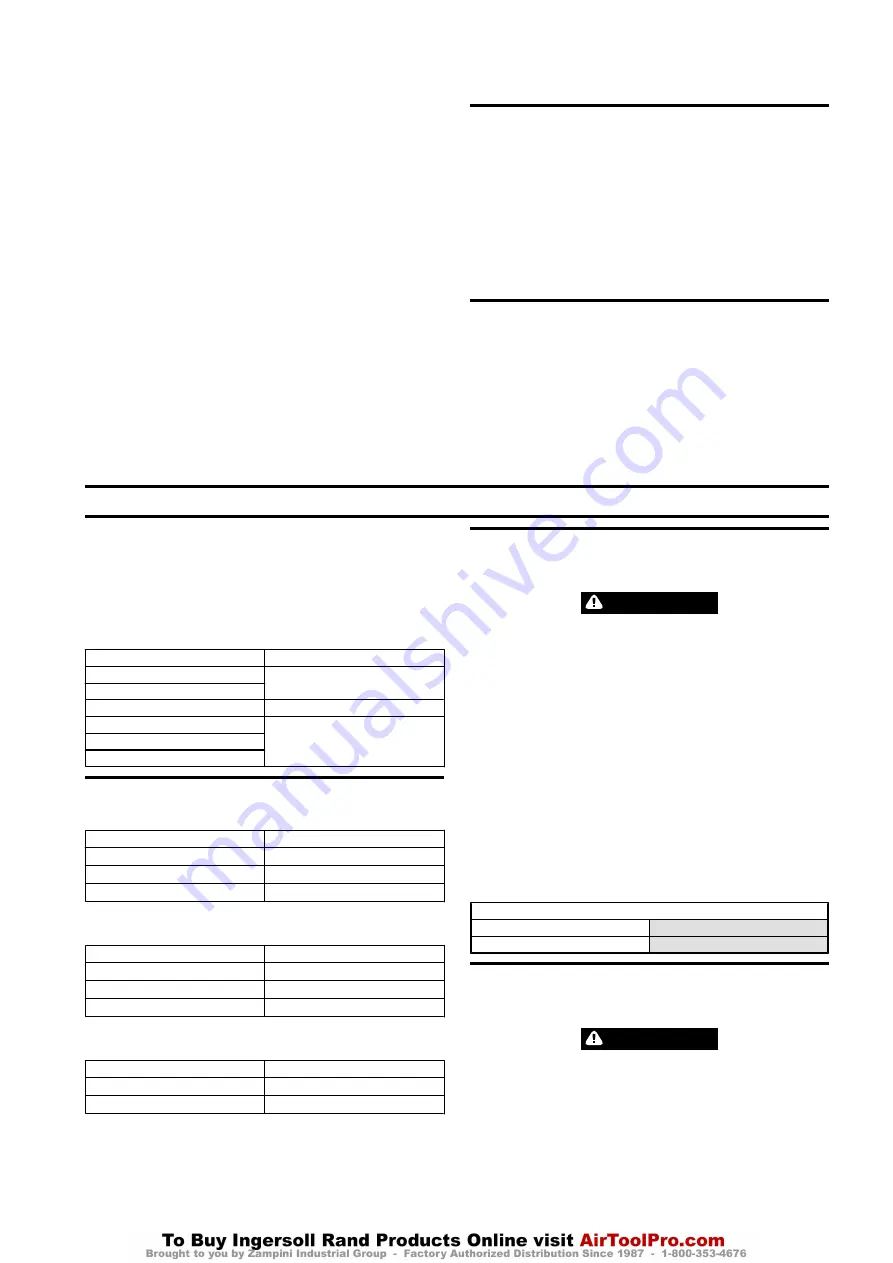

Table 5: Lubrication Intervals

Component

Interval

Check Air Line Lubricator

Daily

Check Motor Oil Level

Check Reduction and Disc Brake Oil

3 Months

Change Motor Oil

1 Year or 1,000 Hours

of Product Operation

Change Gearbox Oil

Change Disc Brake Oil

n

Recommended Lubricants

Table 6: Reduction Gear and Disc Brake Recommended Lubricant Grade

Temperature

Grade Type

Below 32

°

F (0

°

C)

2 EP (ISO VG 68)

32

°

to 80

°

F (0

°

to 27

°

C)

3 EP (ISO VG 100) *

Above 80

°

F (27

°

C)

4 EP (ISO VG 150)

* Units are shipped from factory with 3 EP (ISO VG 100) lubricant.

Table 7: Air Motor Recommended Lubricant Grade

Temperature

Grade Type

Below 32

°

F (0

°

C)

ISO VG 32 (SAE 10W)

32

°

to 80

°

F (0

°

to 27

°

C)

ISO VG 68 (SAE 20W) *

Above 80

°

F (27

°

C)

ISO VG 100 (SAE 30W)

* Units are shipped from factory with ISO VG 68 (SAE 20W) lubricant.

Table 8: Recommended Grease Grade

Temperature

Grade Type

-20

°

to 50

°

F (-30

°

to 10

°

C)

EP 1 multipurpose lithium based grease

30

°

to 120

°

F (-1

°

to 49

°

C)

EP 2 multipurpose lithium based grease

n

Motor

Refer to Dwg. MHP2271 on page 11,

A.

Fill/Breather Plug;

B.

Motor Case;

C.

Level

Plug Position;

D.

Drain Plug Position.

CAUTION

• Do not use synthetic or detergent lubricants in air motor. Synthetic lubricants

will result in oil blowing by piston rings.

The oil level in the motor should be checked daily or at the start of each shift after

accumulated water has been drained off. To drain, locate and remove oil level, pipe

plug (121) in bottom of motor housing (118). Any fluid drained should be disposed

of in an environmentally safe manner.

Correct lubrication is one of the most important factors in maintaining efficient winch

operation. The motor is splash lubricated by the oil in the motor housing and has no

other means of lubrication. It is therefore important to use only high quality, Extreme

Pressure (EP) rust and oxidation inhibiting gear oils or non-detergent motor oils to

ensure maximum performance and minimum downtime for repairs.

Add oil through filler opening until oil flows from level plug hole. Add oil slowly to

prevent spilling. Refer to Table 9 ‘Motor Oil Capacity’ on page 9. Allow oil to settle

before topping off.

When motors are operated in temperatures below freezing, wait long enough at end

of shift for water to separate from oil but not long enough for it to freeze. Failure to

drain the water when the winch is to remain idle for a protracted period at low

temperatures may result in the oil splasher freezing fast. Drain the water then refill

to the level plug. If desired, all the oil may be drained at the end of the shift and

the motor refilled with new oil.

Table 9: Motor Oil Capacity

Capacity

pint

litres

0.5

0.236

n

Reduction Gear and Disc Brake Lubrication

Refer to Dwg. MHP2297 on page 12,

A.

Fill Plug Position;

B.

Inboard Upright;

C.

Drain Plug;

D.

Drum;

E.

Reduction Gear Assembly.

CAUTION

• Do not over fill. Excess oil will reduce operating efficiency and increase oil

temperature.

• Only use synthetic lubricant in reduction gear and disc brake.

The reduction gear and disc brake are filled with oil from the factory. Check oil level

before initial winch operation.

Form MHD56314 Edition 4

9