TLE5012B

Functional Description

User’s Manual

12

Rev. 1.2, 2018-02

configured via SSC interface to use an external clock signal supplied on the IFC pin as the PLL source, instead of

the internal clock. External clock mode is only available in the PWM or SPC interface configurations.

2.2.3

SD-ADC

The

S

igma-

D

elta

A

nalog-

D

igital-

C

onverters (

SD-ADC

) transform the analog GMR voltages and temperature

voltage into the digital domain.

2.2.4

Digital Signal Processing Unit

The Digital Signal Processing Unit (DSPU) contains the:

•

I

ntelligent

S

tate

M

achine (

ISM

), which does error compensation of offset, offset temperature drift, amplitude

synchronicity and orthogonality of the raw signals from the GMR bridges, and performs additional features

such as auto-calibration, prediction and angle speed calculation

•

CO

ordinate

R

otation

DI

gital

C

omputer (

CORDIC

), which contains the trigonometric function for angle

calculation

•

C

apture

C

ompare

U

nit (

CCU

), which is used to generate the PWM and SPC signals

•

R

andom

A

ccess

M

emory (

RAM

), which contains the configuration registers

•

Laser Fuses, which contain the calibration parameters for the error-compensation and the IC default

configuration, which is loaded into the RAM at startup

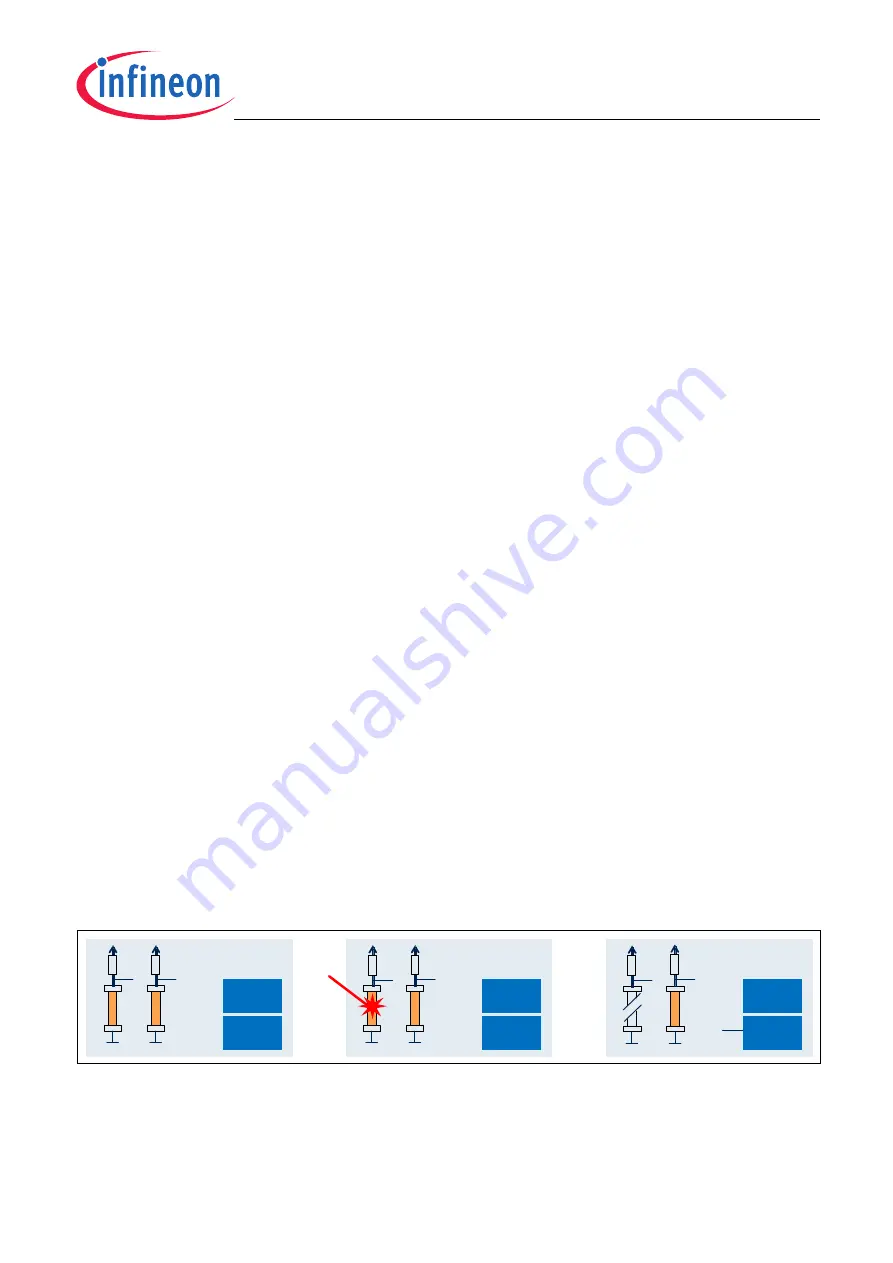

Laser fuses configuration

The laser fuse settings are derivate specific. During production, each and every TLE5012B chip is specifically

configured according to a derivate interface (PWM, SPC, HSM or IIF) and to its specific calibration values (e.g.

offset, amplitude synchronicity, orthogonality). These default values are set by laser fuses, where they remain

stored permanently. At power-on the values stored in the fuses are loaded into flip-flops (placed in the RAM).

Via the SSC interface, these derivate specific configuration values can be overwritten in the RAM. This allows

some programmability such as change of interface (using a IIF derivate as a PWM derivate for example) or to

correct the calibration values (if running the autocalibration mode for example). It is highly recommended to

configure the sensor with customized settings right after a Hardware reset (within the first 120µs, prior to start of

the Built-In Self-Test). If this interval is not sufficient, it is also possible to configure the sensor after the power-on

time. To ensure a correct configuration after power-on time, see recommendations on

. When powered

off or reset, the overwritten values will be lost and the default values stored in the fuses will be reloaded into the

RAM at the next power up.

The

shows how the fuse burning process works. In the original state all fuses are connected to ground

(GND). Once the calibration and derivate specific values are calculated, the information is burned into the fuses,

so that some remain connected to GND (“low” or logical “0”) and some are now pulled up by a resistor (“high” or

logical “1”). When powering the sensor, the RAM is initialized with the values from the fuses.

Figure 2-2 Laser Fuses burning process

DSPU

RAM

F

U

S

E

GND

0

F

U

S

E

GND

…

V

DD

0

V

DD

DSPU

RAM

F

U

S

E

GND

F

U

S

E

GND

…

0

V

DD

0

V

DD

DSPU

RAM

GND

F

U

S

E

GND

…

10

0

V

DD

1

V

DD