The Manual of Ink-jet Printer

29

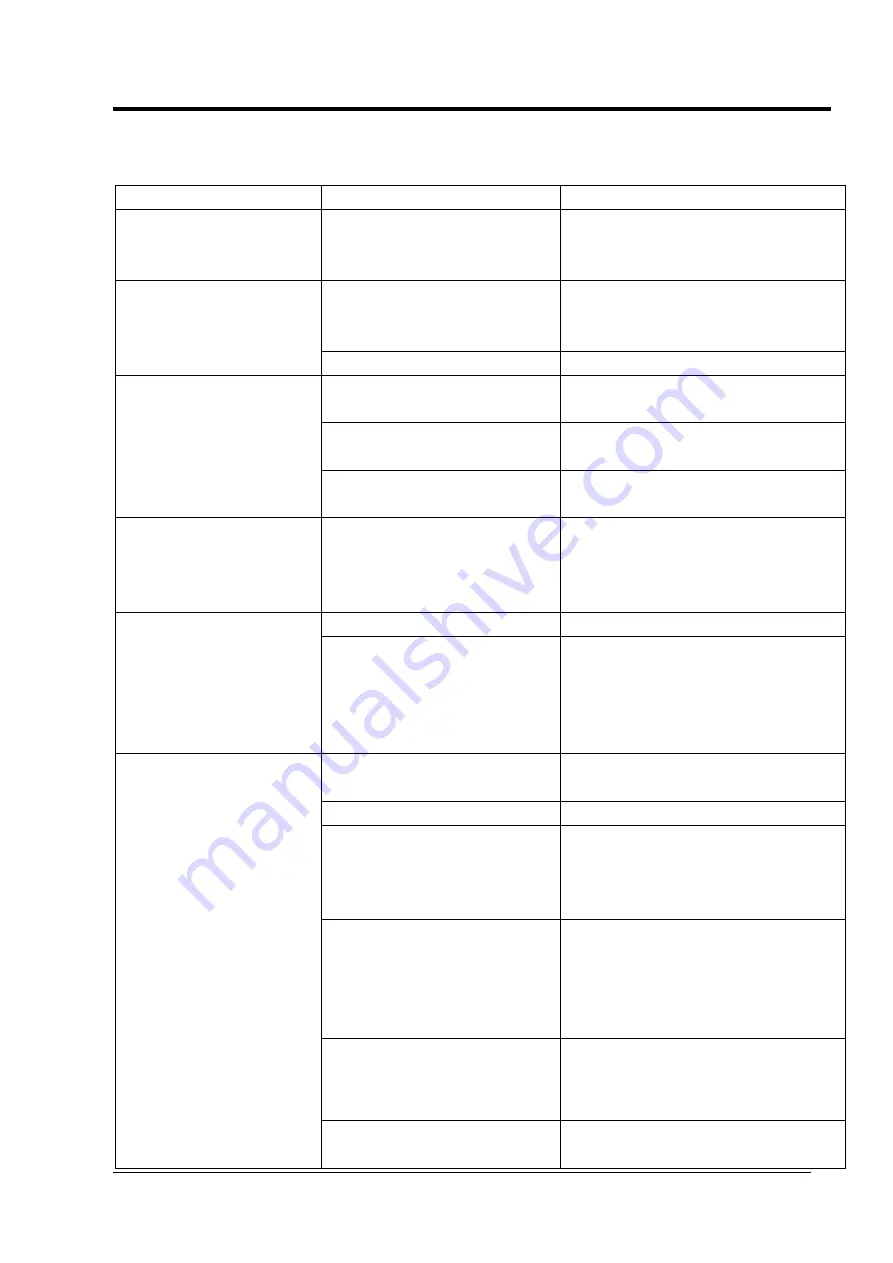

Frequent Troubles Elimination

Ø

System troubles

:

Trouble

Reason

Solution

The

content

is

completed, however is

fuzzy and shadowed.

The distance from print head to

product surface is too far; or

running in fast airflow condition.

Shorten the distance

The print content is not

completed

The surface of print head &

nozzle are dirty, or the inks are

dry.

Purge the print head by cleaner;

Squeeze the ink-cartridge until the inks

spill out.

print head system is damaged.

Replace print head system

Ink leaks out of cartridge

(It’s a normal situation that

after squeeze ink cartridge,

ink will spill out for a

second)

print head stand is not in

horizontal position.

Adjust the stand in horizontal.

Print head installation is not

according to user manual.

Inquire manufacturer to re-install.

Some parts connection are

loose.

Tighten or replace the parts.

Character is not completely

printed

As above, or characters are not

displaying on the touch screen

correctly, check character line

up , left, right, top, bottom

As above, or set characters on screen

correctly

After cleaning the ink

cartridge, a good result is

obtained,

however

the

result goes bad in a very

short time, especially the

tops of characters.

Injector or filter was blocked

Purge or replace the blocked parts.

Some parts of ink system are

loose.(ink cartridge)

Tighten or replace the blocked/dirty

parts.

No dot

’

s are printed at all

Print head cap is not open, or

did not purge print head gap.

Open print head cap, purge print head

gap and squeeze ink cartridge.

Print function is not start up

Press PRINT key

The indicator light of sensor

shows dark or bright all the

time.

l

Adjust installed distance.

l

Check up if the surface has inks

l

Check up the cable plug.

l

Replace the photoelectric sensor

Printing

parameters

are

incorrect

l

Turn down speed rate.

l

Reduce print delay

l

Shorten the files space.

l

When encoder is not connected,

cancel the encoder selection.

Purge or replace the blocked part.

Ink cartridge is empty

Replace a new ink cartridge and purge

it