8

ELECTRICAL CONNECTION

This unit is manufactured for a polarized, grounded 120 or 240 volt/60Hz. Electric power ab-

sorption of each model are shown in the Electrical and Gas Power Table enclosed.

Before connecting the appliance to the electric network, follow the instructions below:

1. fuse and electric feeding installation of your home must support the load of the appliance (see registration label).

2. Power supply system must have an ef

fi

cient earth plate.

3. The outlet or multiple-switch, with a minimum1/8” (3mm) contact opening, has to be easily reached once the

appliance has been installed.

The appliance is supplied without outlet: you need a normal one proper for the electric load.

The power supply cable should not reach a 120°F temperature above the one surrounding.

GAS CONNECTION

All gas connections must be made according to national and local codes. This gas supply (ser-

vice) line must be the same size or grater than the inlet line of the appliance. This range uses a

½”NPT inlet. Sealant on all pipe joints must be resistive to LP gas.

1.

Manual Shut-off Valve: This installer-supplied valve must be installed in the gas service line ahead of the appliance

in the gas stream and in a position where it can be reached quickly in the event of an emergency. The manual

shut-off valve shall be installed properly in order to be accessible when appliance is installed in de

fi

nitive position.

In Massachusetts: A ‘T’ handle type manual gas valve must be installed in the gas supply line to this appliance.

2. Pressure Regulator

1. All heavy duty, commercial type cooking equipment must have a pressure regulator on the incoming service line

for safe and ef

fi

cient operation, since service pressure may

fl

uctuate with local demand. The pressure regulator is

supplied separately with the appliance; regulator has two female threads ½” NPT; it shall be installed properly in

order to be accessible when appliance is installed in de

fi

nitive position.

2. This range can be used with Natural or LP/Propane gas. It is shipped from the factory adjusted for use with natural

gas. The ori

fi

ce hoods must be screwed snug when LP/Propane gas is used(see LP/Propane conversion).

3. The appliance, its individual shut-off valve, and pressure regulator must be disconnected from the gas supply

piping system during any pressure testing of that system at pressure is in excess of 1/2psig(3.45kPa).

4. The appliance must be isolated from the gas supply piping system by closing its individual manual shut-off valve

during any pressure testing of gas supply piping system at test pressures equal to or less than 1/2psig(3.45kPa).

3. Flexible Connections:

1. If the unit is to be installed with

fl

exible couplings and/or quick disconnect

fi

ttings, the installer must use an heavy

duty, AGA design-certi

fi

ed commercial

fl

exible connector of at least ½”(1.3cm)ID NPT(with suitable strain relieves)

in compliance with ANSI Z21.41 and Z21.69 standards.

2. In Massachusetts: The unit must be installed with a 36” (3-foot) long

fl

exible gas connector.

3. In Canada: CAN 1-6.10-88 metal connectors for gas appliances and CAN 1-6.9M79 quick disconnect device for

use with gas fuel.

CAUTION: Leak testing of the appliance shall be conducted according to the manufacturer’s instructions. Before placing the

oven into operation, always check for leaks with a soapy water solution of other acceptable method. DO NOT USE AN OPEN

FLAME TO CHECK FOR LEAKS!

Summary of Contents for UM120

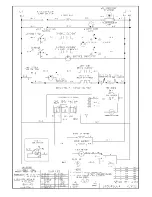

Page 17: ...17 Figure 24 Figure 25 Figure 23 ...

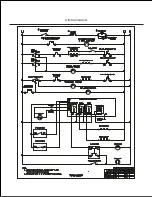

Page 29: ...29 MULTIFUNCTION MODELS ONLY ...

Page 30: ...30 UP90MP ...

Page 31: ...31 UP90VG ...

Page 32: ...32 UPD100FMP ...

Page 33: ...33 UPD90VG ...

Page 34: ...34 UP120SMP ...

Page 35: ...35 UP120VG ...

Page 36: ...36 UP150MP ...

Page 37: ...37 UM150SVG ...

Page 38: ...38 UP90VGG ...

Page 39: ...39 UPD90VGG ...

Page 40: ...40 UP120VGG ...

Page 41: ...41 UP150SVGG ...