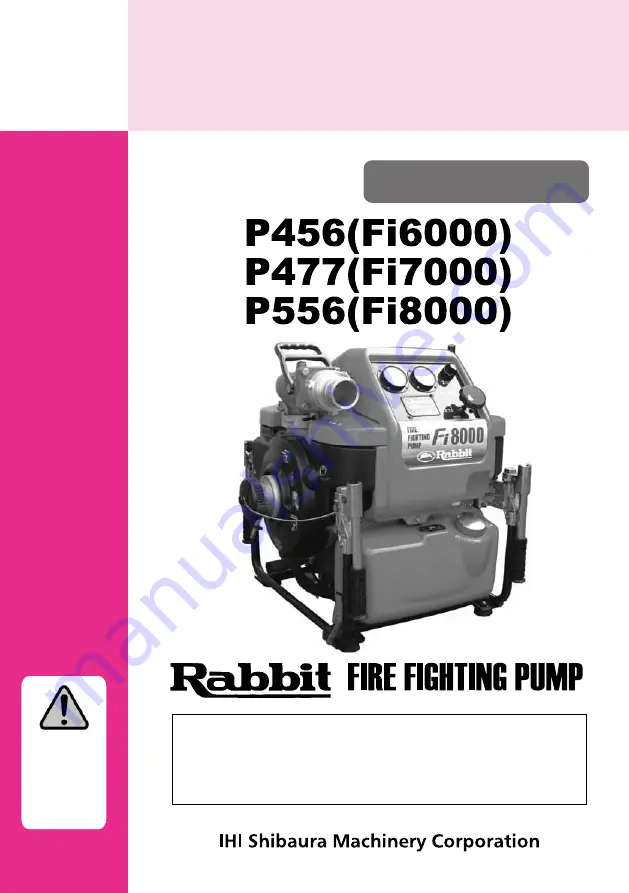

Rabbit

FIRE FIGHTING PUMP

Instruction Manual

Please be

sure to read

this before

starting to

operate the

product.

As for the inspection/maintenance of the product, please

contact the maintenance establishment or distributor

with a certified mechanic for portable fire fighting pump

maintenance.