32

Figure 41

C221894b

1.

Remove 4 bolts (Item 1) from the cover (item 2)

[Figure 41].

2.

Lift the cover (Item 2) [Figure 41] off the auger.

NOTE:

The motor drive chain should be lubricated

every 50 hours or as needed.

(See Service Schedule on Page 30)

Figure 42

C221897c

3.

Lubricate the chain (Item 1) [Figure 42].

4.

Reinstall the cover (Item 2) [Figure 41] on the auger.

5.

Install the 4 bolts (Item 1) [Figure 41].

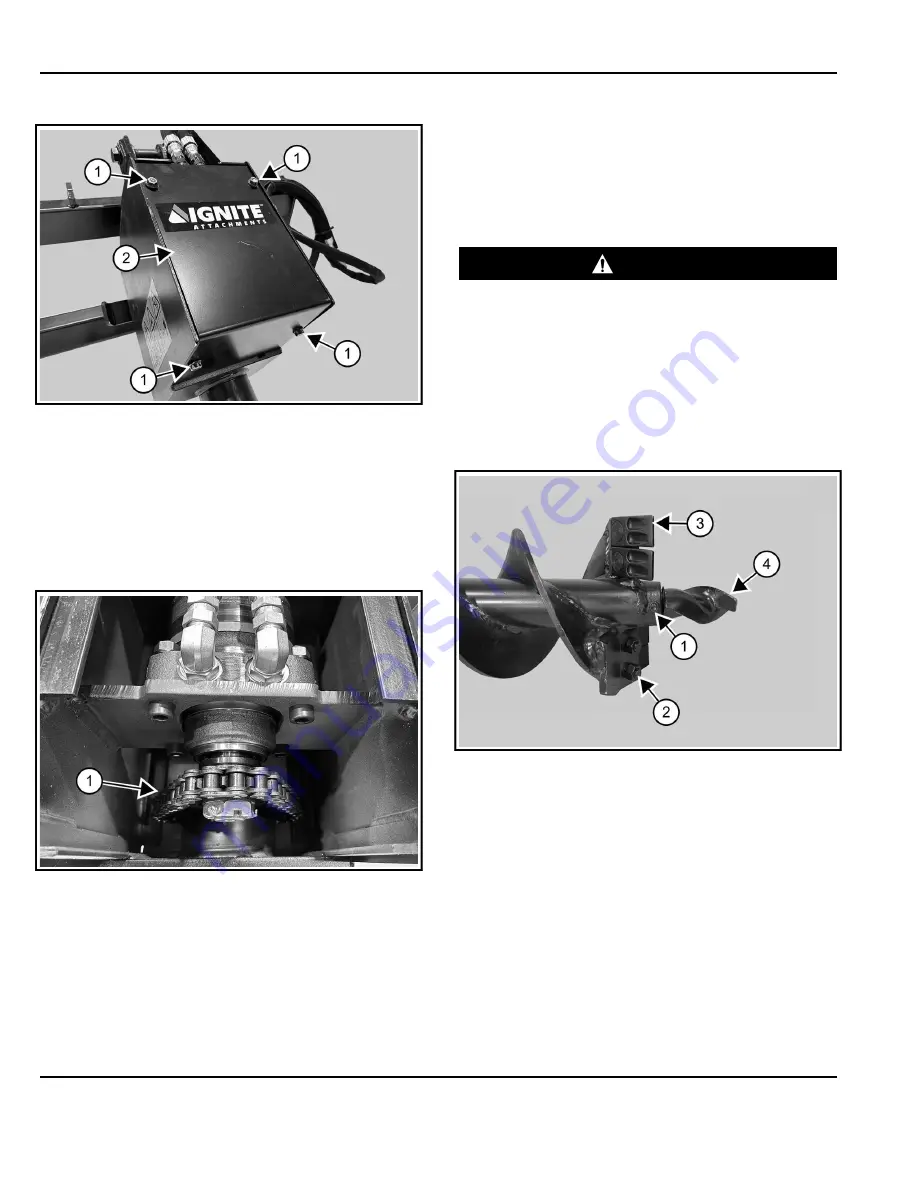

REMOVING AND INSTALLING STANDARD /

HEAVY DUTY AUGER TEETH

Various types and styles of auger points and teeth are

available for different applications. The most common

types are shown below for replacing components.

NOTE:

Your model may vary slightly, but the procedure is

the same.

WARNING

IMPACT AND INJECTION HAZARDS

Flying debris or pressurized fluids can cause serious

injury or death.

Wear safety glasses to prevent eye injury when any

of the following conditions exist:

•

When fluids are under pressure.

•

Flying debris or loose material.

•

Engine is running.

•

Tools are being used.

◂

W-2019

Figure 43

C221418a

1.

Remove the nut (Item 1) and bolt from the point (Item

4) [Figure 43].

2.

Replace the nut and bolt when replacing the point.

3.

Remove the 4 nuts and 4 bolts (Item 2) to remove

the teeth (Item 3) [Figure 43].

4.

Position the tooth on the auger.

Ensure the direction of the tooth cutting edge faces

the same direction of the auger point (Item 4)

[Figure 43] cutting edge.

5.

Replace the 4 nuts (Item 2) and 4 bolts when

installing the teeth (Item 3) [Figure 43].

Summary of Contents for Auger 75 DDH

Page 2: ......

Page 12: ...10 Figure 4 C221899a SAFETY AND TRAINING RESOURCES ...

Page 29: ......

Page 52: ...50 troubleshooting 29 W warranty 48 welding safety 7 ALPHABETICAL INDEX ...

Page 53: ......