10

ACC-SVN190B-EN

W

WA

AR

RN

NIIN

NG

G

P

Prro

op

pe

err F

Fiie

elld

d W

Wiirriin

ng

g a

an

nd

d G

Grro

ou

un

nd

diin

ng

g

R

Re

eq

qu

uiirre

ed

d!!

F

Fa

aiillu

urre

e tto

o ffo

ollllo

ow

w cco

od

de

e cco

ou

ulld

d rre

essu

ulltt iin

n d

de

ea

atth

h o

orr

sse

erriio

ou

uss iin

njju

urry

y..

A

Allll ffiie

elld

d w

wiirriin

ng

g M

MU

US

ST

T b

be

e p

pe

errffo

orrm

me

ed

d b

by

y q

qu

ua

alliiffiie

ed

d

p

pe

errsso

on

nn

ne

ell.. IIm

mp

prro

op

pe

errlly

y iin

nsstta

alllle

ed

d a

an

nd

d g

grro

ou

un

nd

de

ed

d

ffiie

elld

d w

wiirriin

ng

g p

po

osse

ess F

FIIR

RE

E a

an

nd

d E

EL

LE

EC

CT

TR

RO

OC

CU

UT

TIIO

ON

N

h

ha

azza

arrd

dss.. T

To

o a

av

vo

oiid

d tth

he

esse

e h

ha

azza

arrd

dss,, y

yo

ou

u M

MU

US

ST

T ffo

ollllo

ow

w

rre

eq

qu

uiirre

em

me

en

nttss ffo

orr ffiie

elld

d w

wiirriin

ng

g iin

nsstta

alllla

attiio

on

n a

an

nd

d

g

grro

ou

un

nd

diin

ng

g a

ass d

de

essccrriib

be

ed

d iin

n N

NE

EC

C a

an

nd

d y

yo

ou

urr llo

occa

all//

sstta

atte

e//n

na

attiio

on

na

all e

elle

eccttrriicca

all cco

od

de

ess..

1. Ensure Unit power has been disconnected and

locked out.

2. Disconnect both fan motor harnesses from

contactors, install 14 gauge wire harnesses

(supplied in kit) between the controller, fan

contactors and outdoor fan motor harnesses for

both refrigeration circuits. See

3. FOR HEAT PUMP UNITS ONLY, connect Switchover

valve 1 (SOV1) harness (supplied in kit) using the

following steps:

a. Disconnect black wire from SOV1. See

.

b. Reconnect black wire to black wire in kit harness

by making an in-line connection. Securely

attach this in-line connection to adjacent wiring

with wire ties. See

c. Connect terminal with black and orange wires to

the open tab on SOV1. See

.

d. Connect orange wire with stripped end to Rev

valve terminal on low amb controller 1. See

4. FOR HEAT PUMP UNITS ONLY, connect Switchover

valve 2 (SOV2) harness (supplied in kit) using the

following steps:

a. Disconnect blue wire from SOV2. See

.

b. Reconnect blue wire to black wire in kit harness

by making an in-line connection. Securely

attach this in-line connection to adjacent wiring

with wire ties. See

c. Connect terminal with black and orange wires to

the open tab on SOV2. See

.

d. Connect orange wire with strip end to Rev valve

terminal on low amb controller 2. See

.

5. Install jumper harness (supplied in kit) between the

two controllers. See diagram for reference. See

.

6. Install 24VAC harness (supplied in kit) between unit

controller (UC-P5) and the Low Ambient

Controller1. See

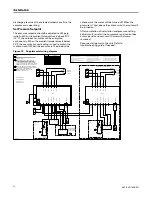

7. For each refrigeration circuit install transducer

wires to controller as per kit diagram. See

8. For each refrigeration circuit install the thermistors

on the outdoor air sensor bracket and connect on

controller as per kit diagram. See

9. Finish wiring installation.

a. Using wire ties, bundle and dress any excess

wires away from sharp edges, moving parts, or

hot tubes.

b. Apply the diagram (supplied in kit) to an open

area on the low voltage access panel. See

for proper replacement.

c. After the settings have been properly adjusted

(see “

), reinstall the

compressor and control box access panels and

secure with screws that were removed.