en

16

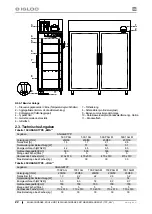

COOLING CABINETS, MEDIUM-FREEZING AND FREEZING CABINETS WITH UPPER AGGREGATE (“AG” TYPE)

www.igloo.pl

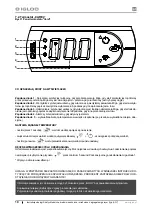

Keep the condenser clean. Dirt may hinder the heat

exchange, causing mainly increase in electric energy

consumption and may cause damage of aggregate

compressor. In “AG” cabinets it is recommended to cle-

an the condenser at least once a year. Clean condenser

lamellas with help of soft brush or paintbrush. If the con-

denser is extremely dirty (blocked lamellas) it is indica-

ted to use vacuum cleaner or compressed nitrogen to

suck / blow the dirt from between lamellas.

The producer shall not be held responsible for damages of the condenser aggregate resulting from non-

observance of condenser cleanliness!

When using the unit as well as during maintenance work, be careful not to damage the temperature sensor

Fig.6 (p.16) !

Door seal should be cleaned only with clean water, without addition of washing agents, and it sho-

uld be thoroughly dried.

The seal cannot come in contact with greasy substances or oils!

During maintenance services it is necessary to check whether doors close in a proper manner.

Test: place a sheet of paper between the seal and the casing and close the door. The paper

should pose felt resistance during an attempt of pulling it out.

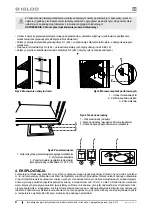

1 – Perforated frame strip

2 – Temperature sensor

Fig. 6 Temperature sensor within the display cabinet

Fig. 8 Exchange of the

fl

uorescent lamp

1 – Starter of the

fl

uorescent lamp

2 – Base pro

fi

le

3 – Casings of the

fl

uorescent lamp and the starter

4 – Fluorescent lamp

5 – Transparent casing of the

fl

uorescent lamp

Fig. 7 Cleaning the condenser

2

1

5

2

2

3

4

5

4

1