5

2

the control plug of the clamp should be placed in the socket (6), and the gas connector plug in the socket of the

quick coupler (7). The gas pipe from the regulator should be connected and secured to the gas connector (16)

located on the back of the housing. Connect the positive pole of the source (5) with the workpiece using a cable

with a clamp. Connect the device's plug to a 230V 50Hz power socket.

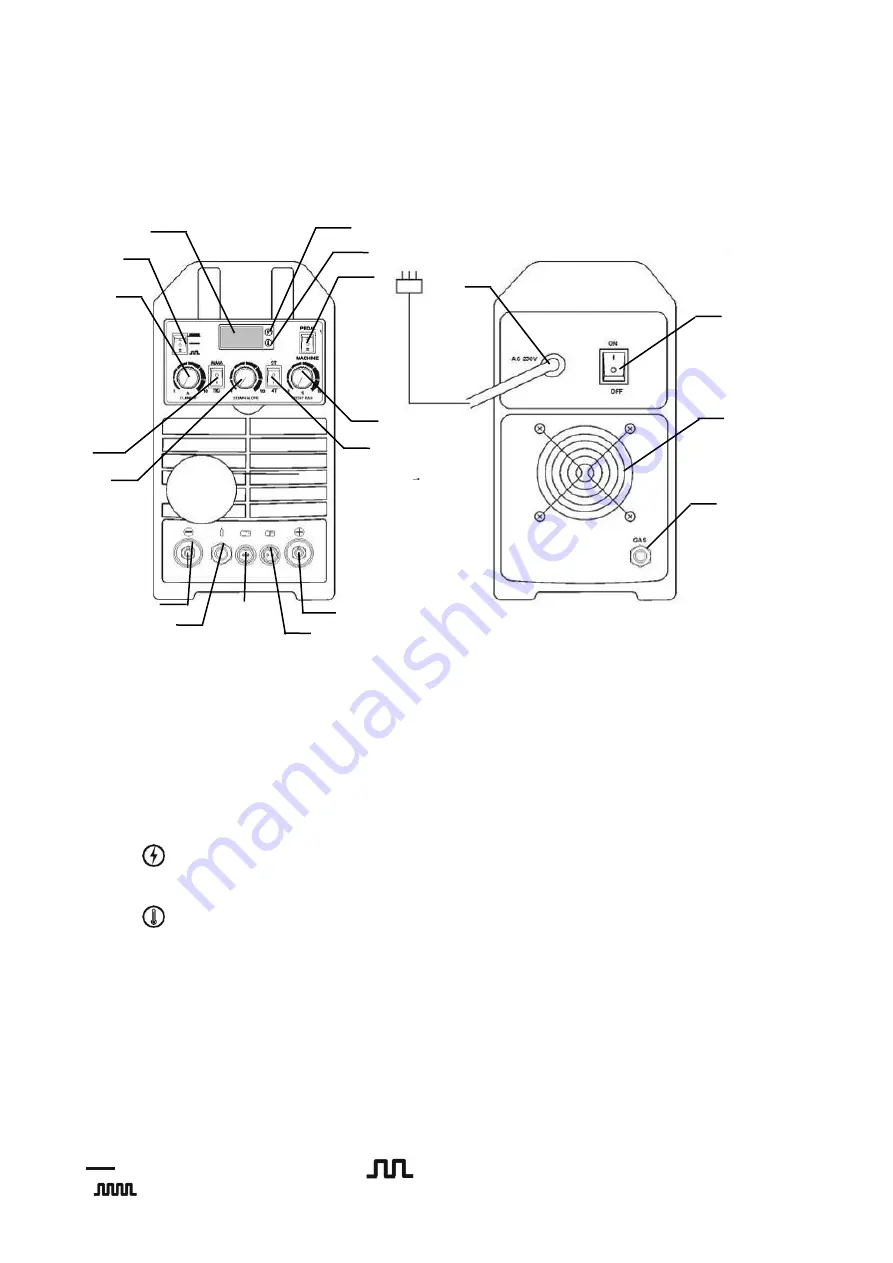

6 DESCRIPTION OF SWITCH FUNCTIONS AND KNOBS

6.1

Front and rear panel

1).Power supply LED

2).Thermal protection diode

3).Remote foot pedal and machine switch

4).Post gas adjustment knob

5).Control mode switch (two-stroke / four-stroke)

6).Display

7).Pulse frequency switch

8).Welding current adjustment knob

9).MMA/TIG switch

10).Down slope adjustment knob

11).Negative polarization socket

12).Shielding gas connection

13).Remote socket

14).Control socket

15).Positive polarity socket Fan

16).Power cord

17).Power on/off

18). Fan

19).Shielding gas cap

6.2 Control panel

Diode

The LED lights up when the device is turned on.

Diode

Overheat protection - the power source is equipped with a thermal automatic overload switch. When the

welder's temperature is too high, the protection disconnects the welding current and the LED lights up. After

the temperature drops, the circuit breaker will reset automatically.

Display of welding parameters

The display shows the welding current in amperes.

Welding method selection switch

The switch is used to select the welding method.

MMA

- welding with covered electrode (MMA),

TIG

-

welding with tungsten electrode in shielding gases.

Pulse frequency switch

Switch active only during TIG welding. Used to control the operation of the pulse:

pulseless welding

pulse frequency welding 1.2 Hz

pulse frequency welding 200 Hz

11

1

4

5

6

7

9

10

16

17

18

19

12 13

14

15

2

3

8