11

Fluid monitoring system - Application solution

UK

In LR DEVICE:

►

In the [ONLINE] area: Click on the IO-Link master�

> The detail window shows the available parameters of the IO-Link master�

►

Change the following parameters in the [IoT] menu:

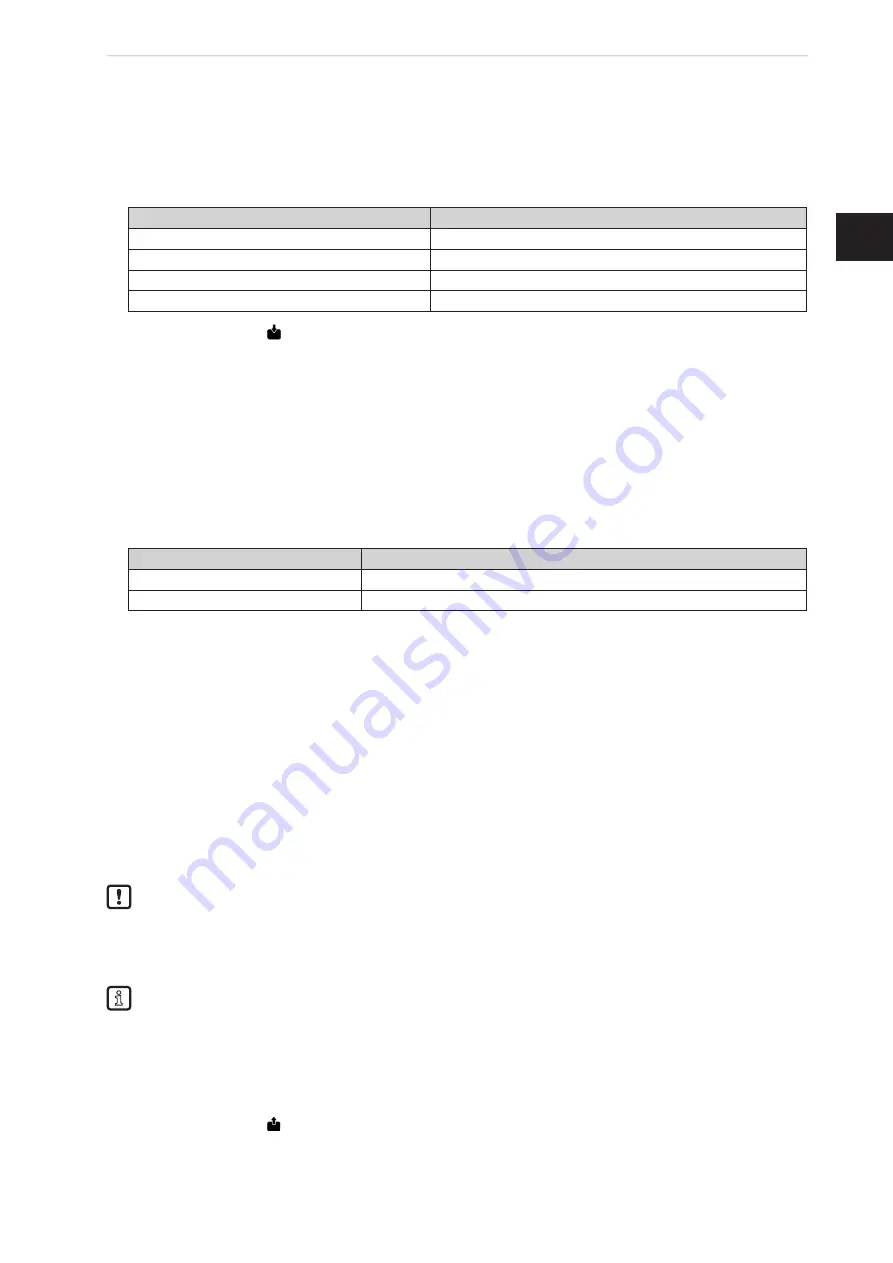

Parameters

Value

IP address LR Agent or SMARTOBSERVER

192�168�0�50

Port LR Agent or SMARTOBSERVER

35101

Interval LR Agent or SMARTOBSERVER

15000

Application tag

Fluid Monitoring System 1

►

Click on the symbol [

IO-LINK

] to write the changed values to the IO-Link master�

7.4 Adapt the calculation of the heat quantity

In the factory settings, the calculation of the heat quantity is rated for the coolant "water"� If a different

coolant is used, execute the following actions:

On the industrial PC:

►

Open the following directory in the file explorer:C:\Program Files\ifm electronic\LR4\LRAgent\

LRAgent_customized\Config\FMS

►

Open the file "Parameters" using the text editor�

►

Change the values of the following parameters according to the selected coolant:

Parameters

Description

SpecificHeatCapacity

Specific heat capacity of the coolant (e.g. 4.18)

Density

Density of the coolant (e.g. 995.0)

►

Save and close the file�

►

Open Windows application "Services"�

► Right mouse click on the service "LR Agent (FMS)"

►

Select the command "Restart" in the context menu�

> The service is restarted�

> Changed parameter values are used to calculate the heat quantity�

8 Parameter setting

The parameters can be set before installation or during operation via the IO-Link interface�

If you change parameters during operation, this will influence the function of the plant�

►

Ensure that there will be no malfunctions in your plant�

During parameter setting the sensors remain in the operating mode� They continue to monitor with the

existing parameter until the parameter setting has been completed�

The sensors' IODD at www�ifm�com contains a complete list of adjustable parameters�

8.1 Change limit values and switch points

Adjust the limit values and switch points of the sensors:

In LR DEVICE:

►

Click on the symbol [

IO-LINK

] to scan the network for available devices�

> LR DEVICE finds the connected IO-Link master�