SU2020 SU2021 SU2621 SU8020 SU8021 SU8621 SU9020 SU9021

Ultrasonic flow meter

48

•

warning via operating status LED.

•

reduced brightness or deactivation of display.

If the unit measures a high internal temperature, the display brightness is automatically

adjusted:

Internal temperature of the unit > 64 °C: brightness is reduced to 25%.

Internal temperature of the unit ≥ 90 °C: display is automatically switched off.

10.6.4.1 Reading via unit keys: internal temperature

u

Go to the [EF] > [DIAG] menu.

u

Select [Internal temperature] and read value.

10.6.4.2 Reading via IO-Link: internal temperature

u

Select [Parameters] > [Diagnosis] > [Temperature].

u

Select [Internal temperature] and read value.

10.6.5 Signal quality

The signal quality of the sensor can be affected by irregularities in the medium (e.g. strong

turbulences, air bubbles, particles or build-up).

The unit detects the signal quality in three stages:

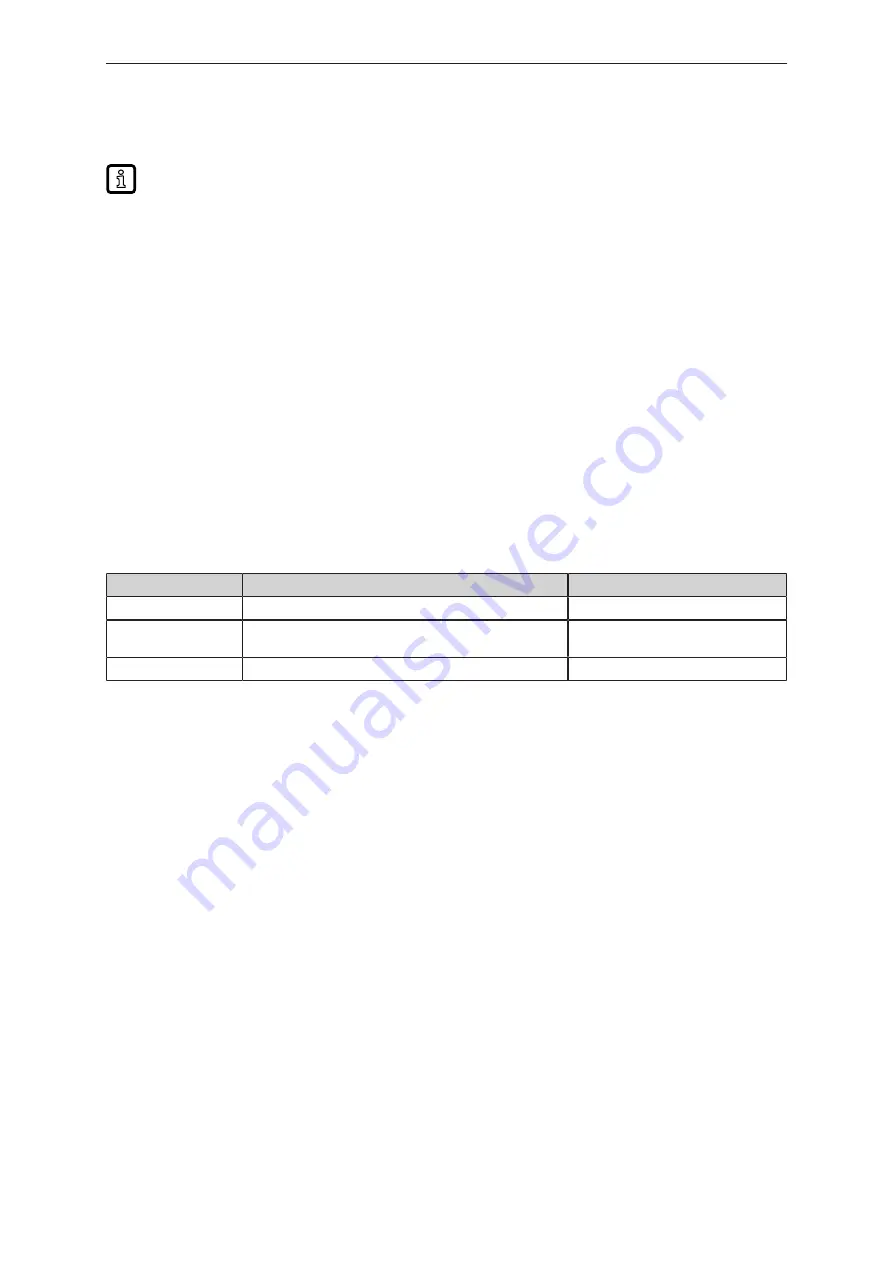

Signal quality

Explanation

Operating status LED

Normal

The unit operates without restrictions (normal operation).

Lights green

Low

The signal quality is disturbed, but the unit is still working

within its specifications.

Lights blue

No signal

No medium is present or no signal can be created.

Flashes red

The current value can be read from the unit’s display or via the IO-Link interface.

In addition, the signal quality can be indicated via a switching signal and/or an LED colour signal. See

also:

•

Switching signal for signal quality (

•

10.6.5.1 Reading via unit keys: signal quality

u

Go to the [EF] > [DIAG] menu.

u

Select [Signal quality] and read value.

10.6.5.2 Reading via IO-Link: signal quality

u

Select [Parameters] > [Diagnosis].

u

Select [Signal quality] and read value.

10.6.6 Operating status LED

The unit has an operating status LED that indicates deviations from normal operation (= diagnostic

cases) by a colour signal.

The function of the operating status LED is adjustable: