45

UK

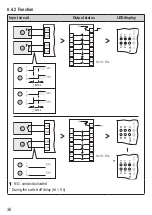

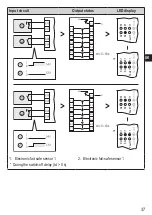

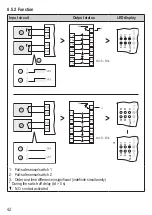

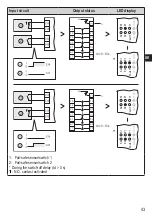

LED display

Cause of the fault

Troubleshooting

K1

E1

T1

POWER

K2

E2

Fault

T

Faul

t

• Connection A2/A3 reversed

► Check wiring

K1

E1

T1

POWER

K2

E2

Fault

T

Faul

t

• Missing link Y4/Y5

► Check wiring

K1

E1

T1

POWER

K2

E2

Fault

T

Fault

• Overvoltage

• Undervoltage

► Check wiring

► Check power supply

K1

E1

T1

POWER

K2

E2

Fault

T

Faul

t

• Overvoltage

• Undervoltage

► Check wiring

► Check power supply

K1

E1

T1

POWER

K2

E2

Fault

T

Faul

t

K1

E1

T1

POWER

K2

E2

Fault

T

Faul

t

• Undervoltage

► Check wiring

► Check power supply