60

NOTES

The ITL-40 is shipped already configured and tested to work with SAM. The ITL-40 ONLY

requires calibration, do NOT reset the ITL-40 configuration.

For square (or rectangular) tanks Hale recommends a 2-point calibration, for T-shaped,

oval, or round tanks Hale recommends the appropriate volume calibration (5 or

9-point).

Always calibrate the ITL then verify CAN communications.

When utilizing master/remote(s) reference section 6.3 of the manual.

When utilizing foam ITL-40s, reference Paragraph 3.7.3., Configuring a display as a

Master with CAN communications, for address 2 and/or address 3 setting information.

When expanding a CAN bus always ensure shielding and proper termination.

Refer to Table 17 for a list of tools and/or consumables required for this procedure.

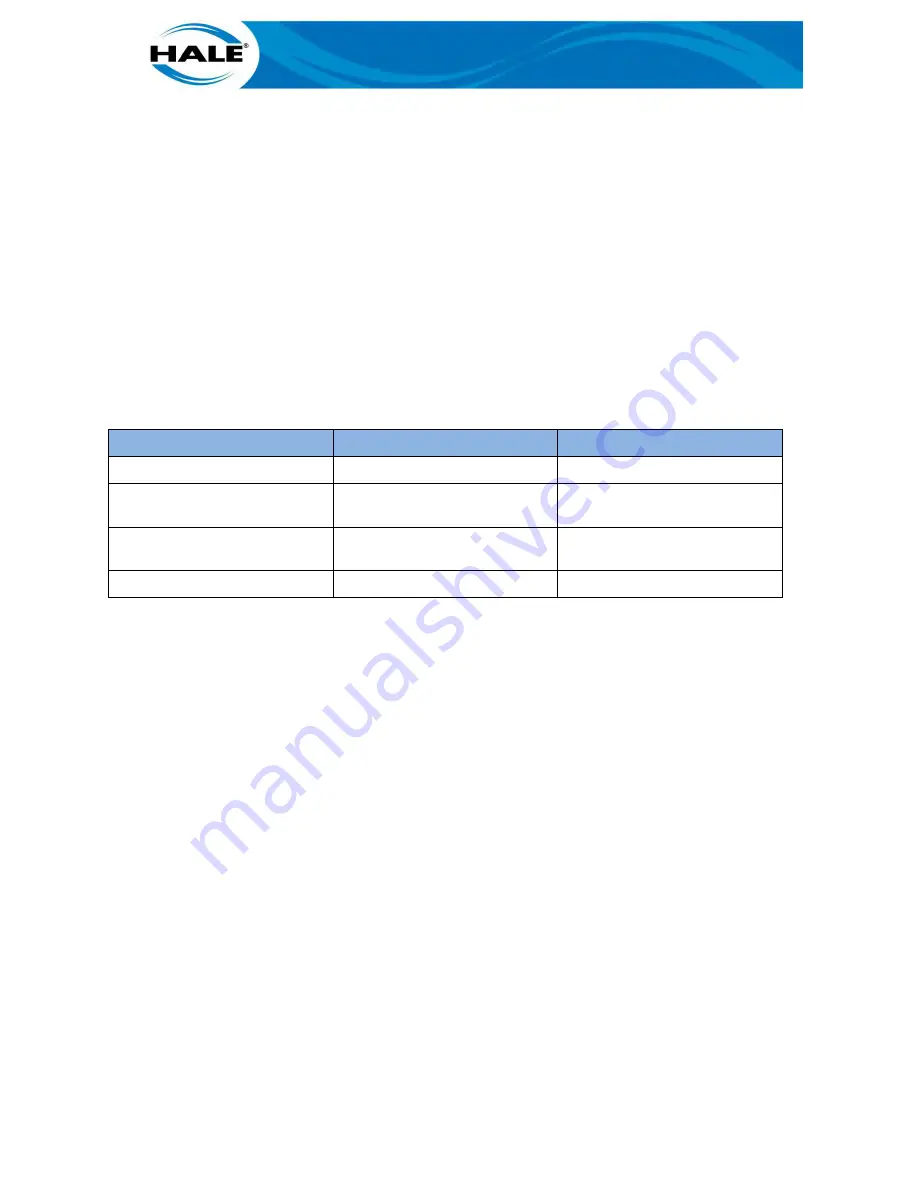

Table 17. ITL–40 Tools And Consumables List

Standard Tools

Special Tools

Consumables

PPE (Eye and Hand Protection)

None

Cable Ties (As Required)

5/16-in Nut Driver

(Or Wrench)

Twister

<See FSG-PL-01505, Sheet 1>

#1 Phillips Screwdriver

6–32 Nyloc SS nut

<P/N 102514>

Wire Cutter

If the ITL–40 fails to display the water level or is damaged; replace the display as follows.

Removal

A.

Open SAM panel.

B.

Note cable tie locations, cut ONLY ties required to R&R ITL–40.

C.

Tag and disconnect electrical connector.

D.

Using screwdriver and nut driver (or wrench), loosen four [4] 6–32 x 3/4-in long

screws and Nyloc nuts. Discard nuts.

E.

Remove three [3] screws and nuts.

F.

Support ITL–40 while removing remaining screw and nut.

G.

Remove ITL–40.

Installation

A.

Align ITL–40 with panel opening and support display during installation.

B.

Hand start four [4] 6–32 x 3/4-in screws and four [4] new 6–32 stainless steel

Nyloc nuts.

C.

Using screwdriver and nut driver (or wrench/socket), tighten four [4] screws and

nuts.

D.

Connect electrical connector according to tags.

E.

Install cable ties cut to R&R ITL–40 as noted.

F.

Close SAM panel.

Summary of Contents for Hale Sam

Page 2: ......

Page 37: ...17 Figure 14 SAM Blue CAN Buss Architecture With Three SAM Control Centers Diagram...

Page 38: ...18 Figure 15 SAM Green CAN Buss Architecture With Three SAM Control Centers Diagram...

Page 39: ...19 Figure 16 SAM Red CAN Buss Architecture With Three SAM Control Centers Diagram...

Page 40: ...20 Figure 17 SAM System Drain And Pneumatic Diagram...

Page 41: ...21 Figure 18 SAM Speaks Diagram...

Page 42: ......

Page 58: ...38 THIS PAGE INTENTIONALLY BLANK...

Page 62: ...42 THIS PAGE INTENTIONALLY BLANK...

Page 192: ...172 THIS PAGE INTENTIONALLY BLANK...

Page 206: ...186 THIS PAGE INTENTIONALLY BLANK...

Page 220: ...200 THIS PAGE INTENTIONALLY BLANK...