18

Concord CXA/H

- Installation and Servicing

INSTALLATION

22 GAS PRESSURE

MANIFOLD PRESSURE

The manifold setting pressure must now be checked and

adjusted as necessary.

Start the adjustment procedure with the system cold, on full

load and with all temperature controls set to maximum to

avoid thermostatic shutdown. Remove the blanking screw in

the manifold setting pressure test point and connect a suitable

gas pressure gauge.

Turn on the electrical supply light the boiler and let it operate

for about 10 minutes to stabilise the burners. Check the

pressure and if necessary adjust it as follows:

CXA 40/H-80/H boilers:

The location of the manifold pressure adjuster on the gas

valve is shown in Frame 21. Remove the dust cover and, using

a screwdriver, turn the screw clockwise to increase or anti

clockwise to decrease the pressure, until it is set to the value

in Table 1.

CXA 90/H and 100/H boiler:

The setting procedure must be done in 2 steps. The location

of the of the manifold pressure adjuster on the gas controls is

shown in Frame 21. Unscrew the bottom electrical plug on the

LH gas valve and pull it off. Remove the dust cover and set the

adjuster on the RH gas valve to the value given in Table 7.

Refit the gas valve electrical plug then set the adjuster on the

LH gas valve to give the burner pressure given in Table 7.

Failure to follow this procedure may result in the correct burner

pressure being set but the 2 gas valve governors not working

correctly.

CXA 110/H and 120/H boilers:

The setting procedure must be done in 2 steps. The location

of the of the manifold pressure adjuster on the gas controls is

shown in Frame 21. Remove the dust cover and, using a

screwdriver, screw in the adjuster on the LH valve nearly fully.

Set the adjuster on the RH gas valve until the manifold

pressure is at the value given in Table 7. Unscrew the LH gas

valve adjuster until the manifold pressure falls then screw it in

again until the pressure is set at the value given in Table 7.

Failure to follow this procedure may result in the correct burner

pressure being set but the 2 gas valve governors not working

correctly.

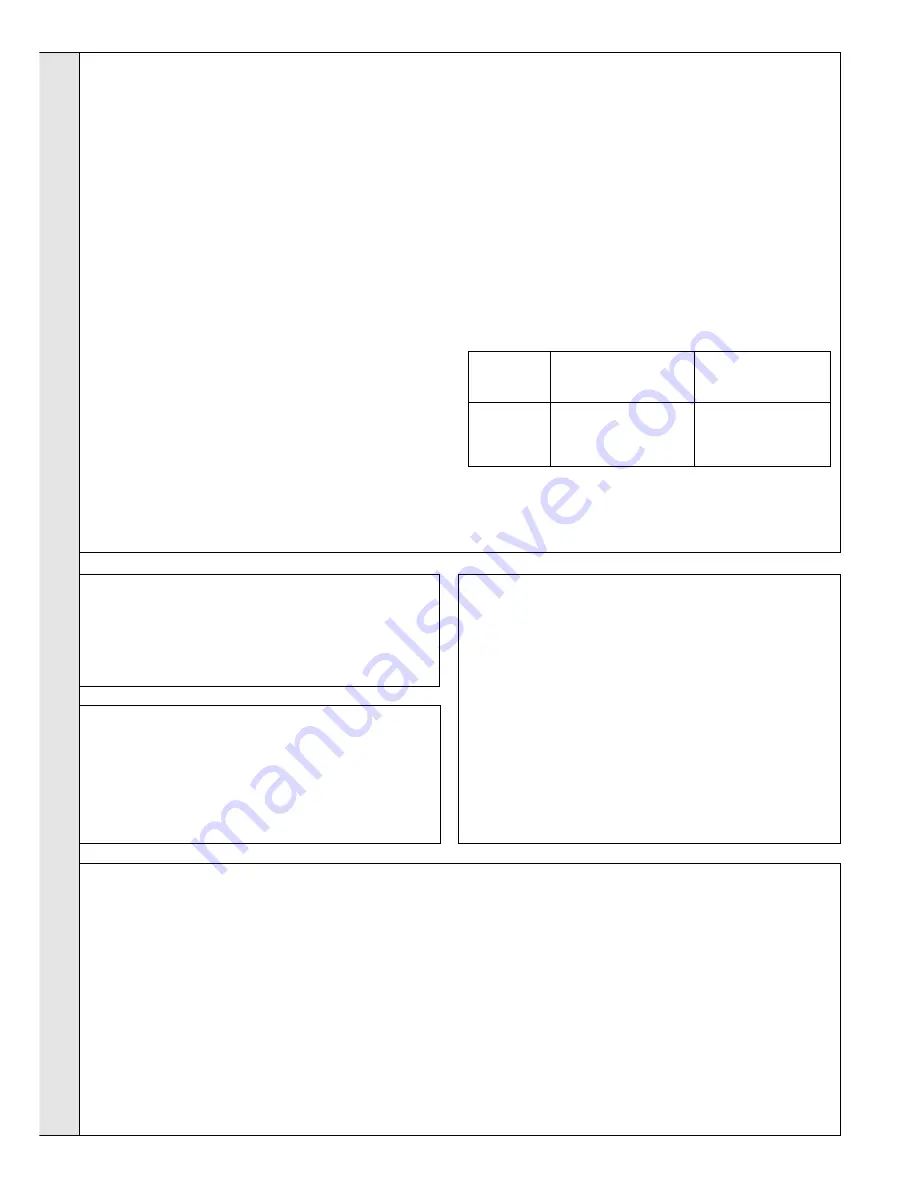

Table 7 - Manifold gas pressure settings

Check there is no spillage of combustion products from the

boiler draught diverter by carrying out a spillage test, as

detailed in BS. 5440:1.

23 SPILLAGE CHECK

24 TESTING

Check that the main burner responds correctly to manual on/

off operations of any controls fitted in the gas control circuit.

Check, in the following manner, the operation of the flame

failure safety device:

1.

Extinguish the main burner and pilot burner by turning off

the main gas inlet cock.

2.

The controls will go to lockout almost immediately and

the lockout light on the control panel will light.

3.

Turn the gas cock again, and press in and release the

lockout reset button on the control box. After a period of

time the controls reset the boiler and it will relight.

4.

Complete the commissioning section of the boiler log book.

25 ADJUSTMENT OF WATER FLOW

RATE THROUGH THE BOILER

26 HANDING OVER

ROUTINE OPERATION

Full instructions covering routine lighting and operation of the

boiler are given on the Lighting and Operation Instruction

Label located on the inside of the casing door.

Draw the attention of the boiler owner or his representative to

the Lighting and Operating Instruction Label on the inside of

the casing door. Give a practical demonstration of the

lighting and shutting down of the boiler.

Describe the function of the boiler and system controls and

show how they are adjusted and used.

Describe the function of the downdraught thermostat if fitted.

Hand these Installation and Servicing Instructions, User's

Instructions and Log book to the customer and request him

to keep them in a safe place for ready reference

IMPORTANT.

Point out to the owner that the boiler must have

regular maintenance and cleaning, at least annually, in order

to ensure reliable and efficient operation. Regular attention

will also prolong the life of the boiler and should preferably

be performed at the end of the heating season.

After servicing complete the service section of the log book

and return to the owner or their representative.

Recommend that a contract for this work should be made

with the regional gas authority or a CORGI registered

heating installer.

At the end of the adjustment procedure replace the dust covers,

disconnect the gas pressure gauge and replace the blanking

screw in the manifold pressure test point.

The gas rate for each size of boiler is given in Table 1 on page 4.

When commissioning the heating/domestic hot water system

the shunt pump must be adjusted to give the minimum flow

rate given in Table 4, when that part of the system intended to

be used for dissipation of residual heat only is in operation.

RH valve adjustment

LH valve (and final)

Boiler

pressure

adjustment pressure

mbar

mbar

CXA 90/H

9.0

9.6

CXA 100/H

10.0

10.7

CXA 110/H

11.6

11.1

CXA 120/H

12.6

12.1

INST

ALLA

TION

Summary of Contents for Concord CXA 100/H

Page 1: ......