- 29 -

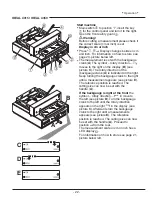

Push the blade changing tool to the top with

your hand (

1.

). First, lightly tighten the middle

blade screw with your other hand (

2.

) and then

both blade screws left and right (

3.

). Remove

the blade changing tool (

R

) (unscrew the

grips).

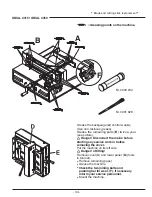

•

Blade and cutting stick replacement

•

Lightly tighten the 2 blade screws on the

elongated holes (

1.

).