59

Installation and Servicing

SECTION 3 - SERVICING

3.31 BOILER SEALING PANEL REPLACEMENT

1. Refer to Sections 3.2 & 3.3.

2. Remove the old seal from the casing.

3. Fit the new seal ensuring correct location

over the fixing pins and the material is

fully located within the casing.

4. Reassemble in reverse order.

5. Check the operation of the boiler. Refer to

Sections 2.24 - 2.27.

3

4

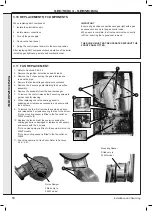

3.30 EXPANSION VESSEL RECHARGING AND REPLACEMENT

Recharging:

A. Refer to Sections 3.2 & 3.3.

B. Remove the charge point dust cover.

C. Recharge the tank pressure to 0.75bar

D. Refit in reverse order

E. Check the operation of the boiler. Refer to Sections 2.24 - 2.27.

Replacement:

1. Refer to Sections 3.2 & 3.3.

2. Close the isolating service valves and drain the (CH) boiler.

Refer to Section 3.22

3.

Remove the clip securing the flexible connecting hose and

disconnect.

4. Remove the two securing screws from the top of the casing

at the same time holding the ignitor bracket to prevent

movement.

5. Hold the expansion vessel and move the ignition assembly

bracket carefully to one side.

6. Pull the bottom of the expansion vessel forward, when free

pull vessel downwards and remove.

7.

Refit in reverse order.

8.

Open the isolating valves and refill the CH system. Refer

to Section 2.15.

9. Check the operation of the boiler. Refer to Sections 2.24 -

2.27.

3

B

SER

VICING

Summary of Contents for VOGUE MAX SYSTEM 15IE

Page 4: ...4 Installation and Servicing ...

Page 6: ...6 Installation and Servicing ...

Page 69: ...69 SHORT LIST OF PARTS Installation and Servicing ...

Page 76: ...76 Installation and Servicing NOTES ...

Page 77: ...77 Installation and Servicing NOTES ...

Page 78: ...78 Installation and Servicing NOTES ...