22

Specifications subject to change without notice.

516 01 3604 04

Defrost

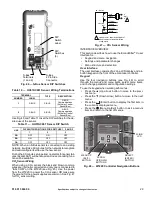

The defrost control mode is a time/temperature sequence.

There are two time components: The continuous run period

and the test/defrost cycle period. The temperature compo

-

nent is provided by Defrost Thermostat 1 and 2 (DFT1 and

DFT2) mounted on the outdoor coil.

The continuous run period is a fixed time period between

the end of the last defrost cycle (or start of the current Heat

-

ing cycle) during which no defrost will be permitted. This pe

-

riod can be set at 30, 60, 90 or 120 minutes by changing the

positions of DIP switches SW1 and SW2 (see Fig. 37 and

Table 7). The default run period is 60 minutes for size 120

units.

Shorting the jumpers for a period of 5 to 20 seconds by

-

passes the remaining continuous run period and places the

unit in a Forced Defrost mode. If the controlling DFT is

closed when this mode is initiated, the unit will complete a

normal defrost period that will terminate when the con

-

trolling DFT opens or the 10 minute defrost cycle limit is

reached. If the controlling DFT is open when this mode is

initiated, the Defrost cycle will run for 30 seconds. Both

modes end at the end of the Defrost cycle.

Fig. 37 — DIP Switch Settings - Defrost Board

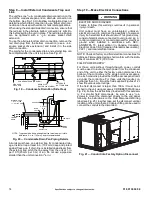

UNIT WITHOUT THRU-BASE CONNECTION KIT

Pass the thermostat control wires through the bushing on

the unit end panel. Route the wire through the snap-in wire

tie and up to the web bushing near the control box. Route

the wire through the bushing and into the bottom left side of

the control box after removing one of the two knockouts in

the corner of the box. Using a connector at the control box

to protect the wire as it passes into the control box. Pull the

wires over to the terminal strip at the upper left corner of the

Central Terminal Board (CTB). Use the connector at the

control box and the wire tie to ensure that the thermostat

wire is tight and will not be damaged by contact with the

condenser coil. See Fig. 38.

NOTE: If thru-the-bottom connections accessory is used,

refer to the accessory installation instructions for information

on routing power and control wiring.

Fig. 38 — Thermostat Wire Routing

HEAT ANTICIPATOR SETTINGS

Set heat anticipator settings at 0.14 amp for the first stage

and 0.14 amp for second-stage heating, when available.

ELECTRIC HEATERS

RHH units may be equipped with field-installed accessory

electric heaters. The heaters are modular in design, with

heater frames holding open coil resistance wires strung

through ceramic insulators, line-break limit switches and a

control contactor. One or two heater modules may be used

in a unit.

Heater modules are installed in the compartment below the

indoor (supply) fan outlet. Access is through the indoor ac

-

cess panel. Heater modules slide into the compartment on

tracks along the bottom of the heater opening. See Fig. 39.

CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage.

Not all available heater modules and single point boxes

may be used in every unit. Use only those heater mod

-

ules that are UL listed for use in a specific size unit. Re

-

fer to the label on the unit cabinet for the list of approved

heaters and single point boxes.