SERVICE AND TECHNICAL SUPPORT MANUAL

Gas Furnace: F9MES

Specifications subject to change without notice.

440 04 4900 02

25

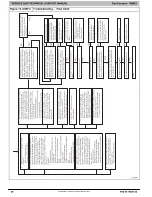

Figure 16

Troubleshooting

−

Flow Chart

Is

LE

D

s

tat

us l

ig

ht

ON

s

ol

id

,

al

te

rn

atel

y

flashi

ng

bri

ght

-di

m

-b

rig

ht-

di

m

li

ke a

hea

rtb

ea

t, o

r fl

ashi

ng

ON

a

nd

O

F

F

?

Is

th

er

e 2

4V

at

2

4V

A

C

a

nd C

O

M?

Is

th

er

e

2

20V

at L1 an

d

N

E

U

T

R

A

L?

Is

th

e 2

4V

f

use

op

en

?

Is

do

or

s

w

itc

h cl

o

sed

?

R

epl

a

ce t

ra

nsf

orm

er

.

R

epl

a

ce do

or

sw

itch

.

Is

th

er

e 2

20V

goi

ng t

o s

w

itch

?

Clo

se

th

e

d

oo

r s

w

itc

h.

Is

ci

rc

ui

t

bre

ak

er cl

ose

d?

C

heck

fo

r co

nti

nui

ty

in

w

ire

from

ci

rcui

t

br

ea

ke

r to

fu

rn

ac

e.

C

lo

se

ci

rc

ui

t b

re

ak

er a

nd

go

ba

ck

to

ST

ART

.

Is

LE

D

s

tat

us l

ig

ht

al

te

rn

atel

y fl

a

shi

n

g

bri

g

ht-

di

m

-b

rig

ht-

di

m

li

ke a h

ea

rtb

eat

?

D

ete

rm

ine s

tat

us c

od

e. T

h

e st

atu

s co

d

e

is

a si

ngl

e

or

t

w

o

di

gi

tn

um

be

r

w

ith

t

he

first num

b

er det

erm

in

ed b

y

the num

b

er of

shor

t fl

ash

es a

nd

th

e se

con

d

num

be

r

afte

r

the pl

us (+

)

si

g

n,

the num

b

er

of

lo

ng

flash

es.

To

r

eca

ll a s

tat

us

c

ode

: B

rie

fly

(

2

–

3

seco

nds

) c

onn

ect

th

e

T

E

S

T

/TW

IN

term

in

al

to t

he

“C

”

the

rm

ost

at t

erm

in

al

w

ith

a j

u

m

per

w

ire t

o b

egi

n st

atu

s co

de

re

cov

er

y

an

d

com

po

nen

t t

est.

If a

pr

evi

o

us s

tat

us c

o

de i

s

pr

es

en

t, t

he

c

od

e

w

ill

re

pe

a

t 4

tim

es t

h

en

go

on t

o c

om

po

nen

t t

est.

If n

o

pre

vi

ou

s

co

d

e is p

re

se

n

t, a

co

m

p

on

en

t te

st

w

ill

begi

n w

ith

o

ut

flashi

ng an

y sta

tus cod

es

.

C

o

mpon

en

t T

e

s

t

S

e

qu

enc

e

: Gas

valv

e

an

d

h

um

id

ifie

r

w

ill n

ot

be

t

ur

ne

d o

n.

In

d

uce

r

m

oto

r w

ill sta

rt

a

nd

r

em

ai

n o

n u

nt

il

the

en

d o

f th

e bl

o

w

e

r t

est,

th

en

off.

T

he

fol

lo

w

ing c

om

po

ne

nts

ar

e o

n f

or

10

–

1

5

seco

nds

ea

ch i

ndi

vi

dual

ly

: h

ot s

ur

fac

e

igni

te

r, bl

o

w

er spe

eds

: FA

N

(if

pr

es

ent

),

HE

A

T

, COOL

.

W

as there

a p

revi

ous

stat

us c

od

e?

Go t

o s

ecti

o

n b

el

o

w

fo

r t

he fl

ash

ed

sta

tus

cod

e.

D

oes

the

co

ntr

ol

r

esp

on

d t

o

W

, Y

, a

nd

G

(24V

) t

herm

o

stat

si

g

nal

s?

R

un s

ystem

t

hr

ou

gh

a

h

eat

, o

r c

ool

in

g

cy

cl

e t

o c

heck

op

er

ati

o

n. S

tat

us c

od

es

are

er

ase

d

afte

r 8

6

hou

rs.

Is

24V

pr

es

ent

at

W

, Y

o

r G

th

erm

ost

at

term

in

al

s o

n t

he f

ur

nac

e c

ont

rol

?

C

heck

ro

om

th

erm

os

tat

or

in

ter

co

nne

cti

n

g ca

bl

e

.

Discon

nec

t all

the

th

erm

os

tat

wire

s fr

o

m

the fur

nac

e

cont

rol

.

D

oes

the

p

robl

em

r

epe

at

w

he

n u

si

ng

a

ju

m

per

w

ire

?

R

epl

a

ce f

ur

nac

e c

ont

rol

.

T

he th

erm

os

tat

is

n

ot c

om

pati

bl

e

w

ith

the

fur

nac

e co

ntr

ol

.

E

ithe

r i

nstal

l a

bal

la

st

resist

or

, co

nn

ect t

he

C

fu

rn

ace

co

ntr

ol

the

rm

osta

t te

rm

inal

to

the

th

erm

os

tat,

o

r

repl

ace

th

e t

herm

o

stat

.

YE

S

NO

YE

S

YE

S

YE

S

YE

S

Y

E

S

YE

S

YE

S

STAR

T

YE

S

YE

S

NO

NO

NO

NO

NO

NO

NO

NO

YE

S

NO

NO

Trou

bles

hoo

tin

g

Guide

R

epl

a

ce f

ur

nac

e c

ont

rol

.

YE

S

Insp

ect s

ec

ond

ar

y

vol

tag

e (

24V

)

w

iri

ng,

in

cl

udi

ng

th

erm

ost

at l

ea

ds f

or s

ho

rt

circuit

.

R

epl

a

ce f

us

e

NO

Is

LE

D

s

tat

us l

ig

ht

ON

s

ol

id

?

NO

YE

S

T

he

co

nt

ro

l is l

ock

ed

o

ut

a

n

d

w

ill

au

to

-

rese

t a

fte

r 7

2 m

inu

tes.

L

ock

out

coul

d b

e

due

to

an

y

of

th

e fol

lo

w

in

g:

-

F

la

m

e s

en

se ci

rcui

t fai

lur

e.

-

G

as

va

lv

e r

elay

st

uc

k op

en

.

-

S

oft

w

a

re che

ck

err

or.

R

eset

po

w

er

to

cl

e

ar l

ock

out.

R

e

pl

ac

e

cont

rol

if

co

de

re

pe

ats.