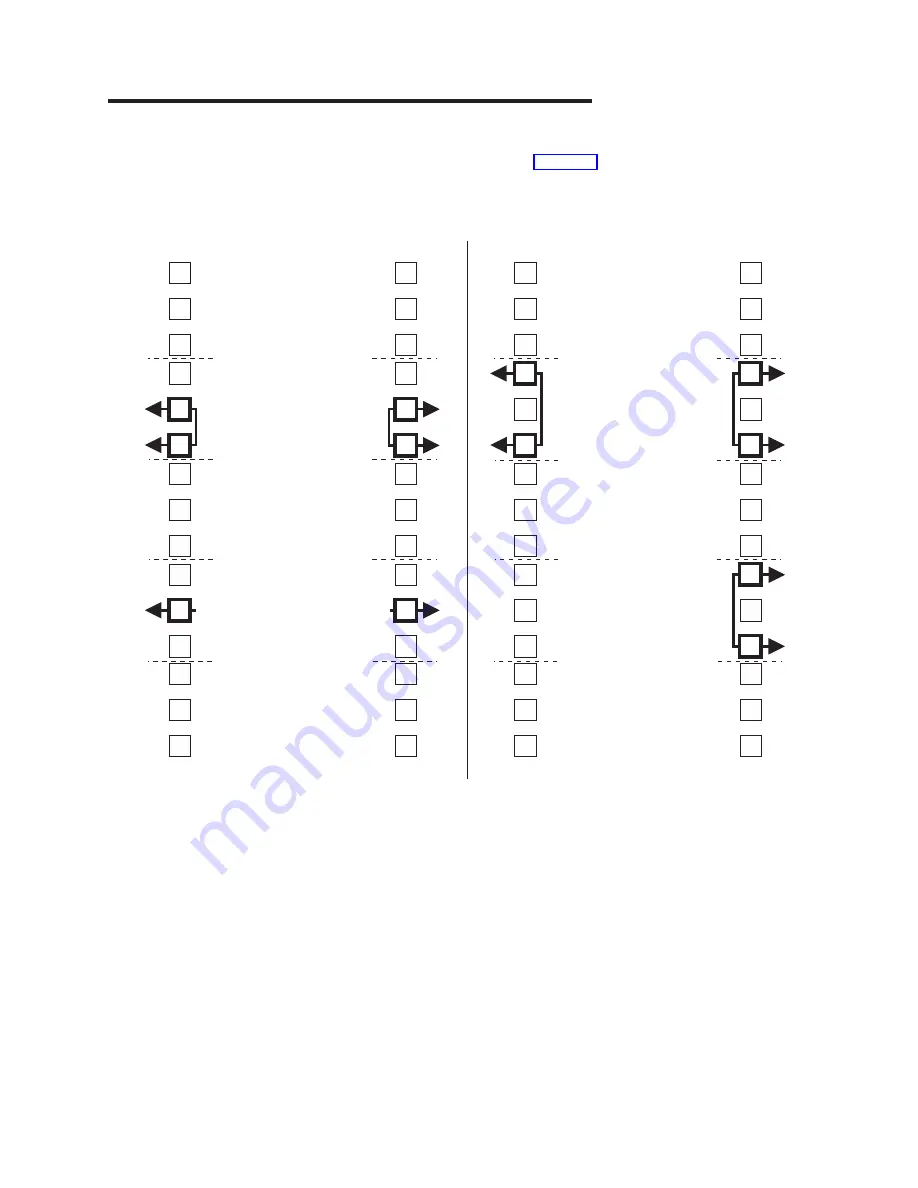

Appendix A. Rack Installation Instructions

The following reduced-size illustration in Figure 42 of the front and the back of the

rack-mounting template shows where to place the clip nuts or cage nuts when

installing your appliance in a rack.

Rack Mounting

Template

REAR

Rack Mounting

Template

FRONT

Slide rail

(

)

Rear Left

Slide rail

(

)

Front Right

Slide rail

(

)

Front Left

Slide rail

(

)

Rear Right

Release-latch-bracket

assembly

(

)

Front Left

Release-latch-bracket

assembly

(

)

Front Right

Hinge bracket

(

)

Rear Right

Figure 42. Rack mounting template

© Copyright IBM Corp. 2001

105

Summary of Contents for totalstorage 200

Page 1: ...IBM TotalStorage Network Attached Storage Models 200 and 225 Service Guide ...

Page 2: ......

Page 3: ...IBM TotalStorage Network Attached Storage Models 200 and 225 Service Guide ...

Page 8: ...vi Models 200 and 225 Service Guide ...

Page 12: ...x Models 200 and 225 Service Guide ...

Page 14: ...xii Models 200 and 225 Service Guide ...

Page 16: ...xiv Models 200 and 225 Service Guide ...

Page 30: ...14 Models 200 and 225 Service Guide ...

Page 58: ...42 Models 200 and 225 Service Guide ...

Page 108: ...92 Models 200 and 225 Service Guide ...

Page 120: ...104 Models 200 and 225 Service Guide ...

Page 130: ...114 Models 200 and 225 Service Guide ...

Page 134: ...118 Models 200 and 225 Service Guide ...

Page 149: ...Appendix D Notices 133 ...

Page 150: ...134 Models 200 and 225 Service Guide ...

Page 151: ...Appendix D Notices 135 ...

Page 152: ...136 Models 200 and 225 Service Guide ...

Page 153: ...Appendix D Notices 137 ...

Page 154: ...138 Models 200 and 225 Service Guide ...

Page 167: ...Appendix D Notices 151 ...

Page 179: ......