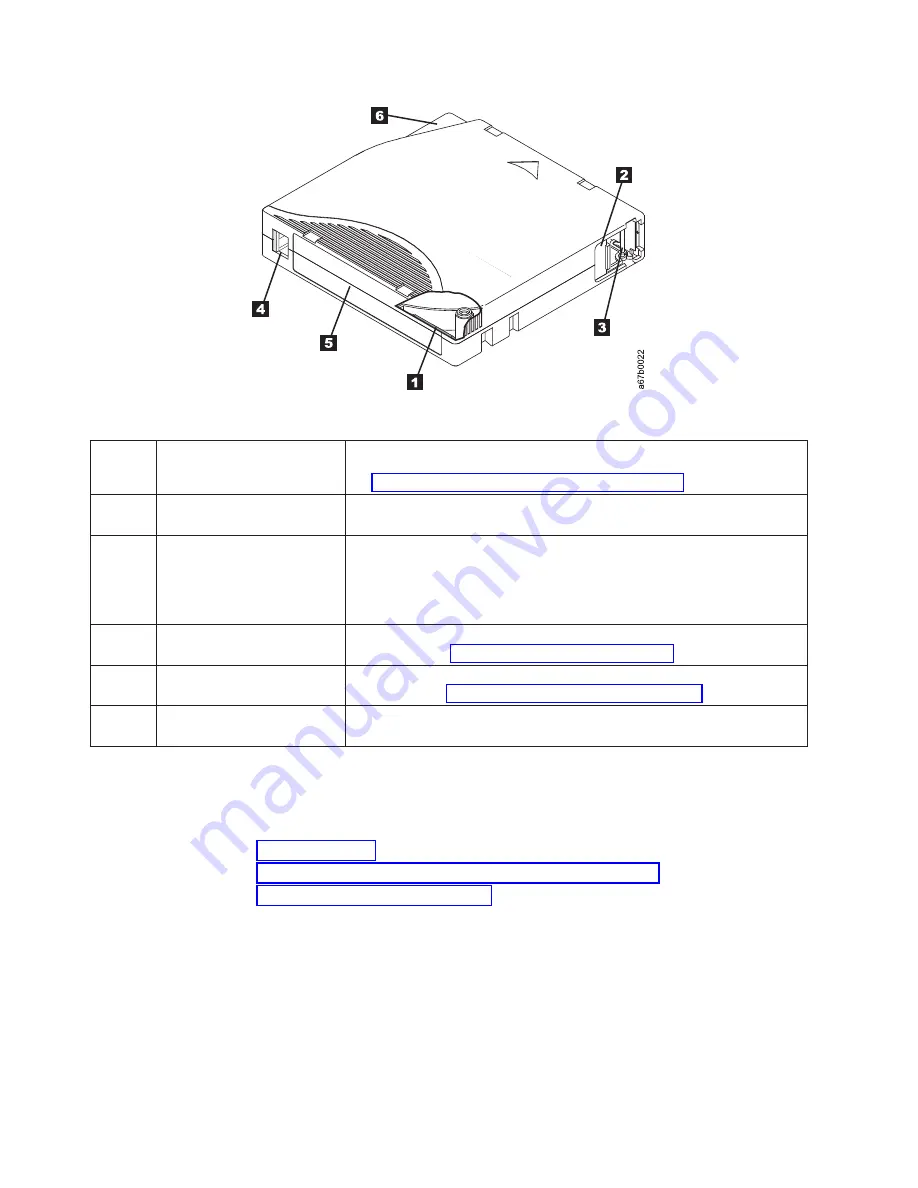

1

LTO cartridge memory

a chip that contains information about the cartridge and the tape, as well

as statistical information about the cartridge's use (For more information,

see “Cartridge Memory Chip (LTO-CM)” on page D-7.)

2

Cartridge door

protects the tape from contamination when the cartridge is out of the

drive

3

Leader Pin

The tape is attached to a leader pin, behind the cartridge door. When the

cartridge is inserted into the drive, a threading mechanism pulls the pin

(and tape) out of the cartridge, across the drive head, and onto a

non-removable take-up reel. The head can then read or write data from or

to the tape.

4

Write-protect Switch

prevents data from being written to the tape cartridge (For more

information, see “Write-Protect Switch” on page D-7.)

5

Label area

provides a location to place a label (To obtain tape cartridges and bar

code labels, see “Ordering Media Supplies” on page D-17).

6

Insertion guide

a large, notched area that prevents the cartridge from being inserted

incorrectly

Types of Cartridges

Ultrium media is available in the following types:

v

v

“WORM (Write Once, Read Many) Cartridge” on page D-8

v

“Cleaning Cartridge” on page D-9

Data Cartridge

All generations of IBM Ultrium data cartridges contain 1/2-inch, dual-coat,

metal-particle tape. When processing tape in the cartridges, Ultrium Tape Drives

use a linear, serpentine recording format.

Each generation of data cartridge is identified by case color, native data capacity,

recording format and nominal cartridge life.

Figure D-3. The IBM LTO Ultrium Data Cartridge

D-6

TS3310 Tape Library Maintenance Information

Summary of Contents for System Storage TS3310

Page 2: ......

Page 6: ...iv TS3310 Tape Library Maintenance Information...

Page 8: ...vi TS3310 Tape Library Maintenance Information...

Page 18: ...xvi TS3310 Tape Library Maintenance Information...

Page 20: ...xviii TS3310 Tape Library Maintenance Information...

Page 22: ...xx TS3310 Tape Library Maintenance Information...

Page 28: ...1 6 TS3310 Tape Library Maintenance Information...

Page 76: ...3 14 TS3310 Tape Library Maintenance Information...

Page 92: ...4 16 TS3310 Tape Library Maintenance Information...

Page 196: ...6 94 TS3310 Tape Library Maintenance Information...

Page 242: ...7 46 TS3310 Tape Library Maintenance Information...

Page 378: ...8 136 TS3310 Tape Library Maintenance Information...

Page 382: ...9 4 TS3310 Tape Library Maintenance Information...

Page 390: ...10 8 TS3310 Tape Library Maintenance Information...

Page 396: ...A 6 TS3310 Tape Library Maintenance Information...

Page 415: ...Library Electrical Block a66mi038 Appendix C Library Diagrams C 7...

Page 416: ...Library Control Blade a66mi042 C 8 TS3310 Tape Library Maintenance Information...

Page 417: ...Library Control Blade Functions a66mi039 Appendix C Library Diagrams C 9...

Page 418: ...Accessor Control Block a66mi040 C 10 TS3310 Tape Library Maintenance Information...

Page 421: ...a66mi036 Appendix C Library Diagrams C 13...

Page 423: ...Library Power System a66mi044 Appendix C Library Diagrams C 15...

Page 424: ...a66mi043 C 16 TS3310 Tape Library Maintenance Information...

Page 484: ...D 60 TS3310 Tape Library Maintenance Information...

Page 494: ...E 10 TS3310 Tape Library Maintenance Information...

Page 498: ...F 4 TS3310 Tape Library Maintenance Information...

Page 504: ...G 6 TS3310 Tape Library Maintenance Information...

Page 520: ...H 16 TS3310 Tape Library Maintenance Information...

Page 526: ...X 6 TS3310 Tape Library Maintenance Information...

Page 529: ......

Page 530: ...Part Number 46X4072 Printed in USA GA32 0478 08 1P P N 46X4072...