Positioner Mode

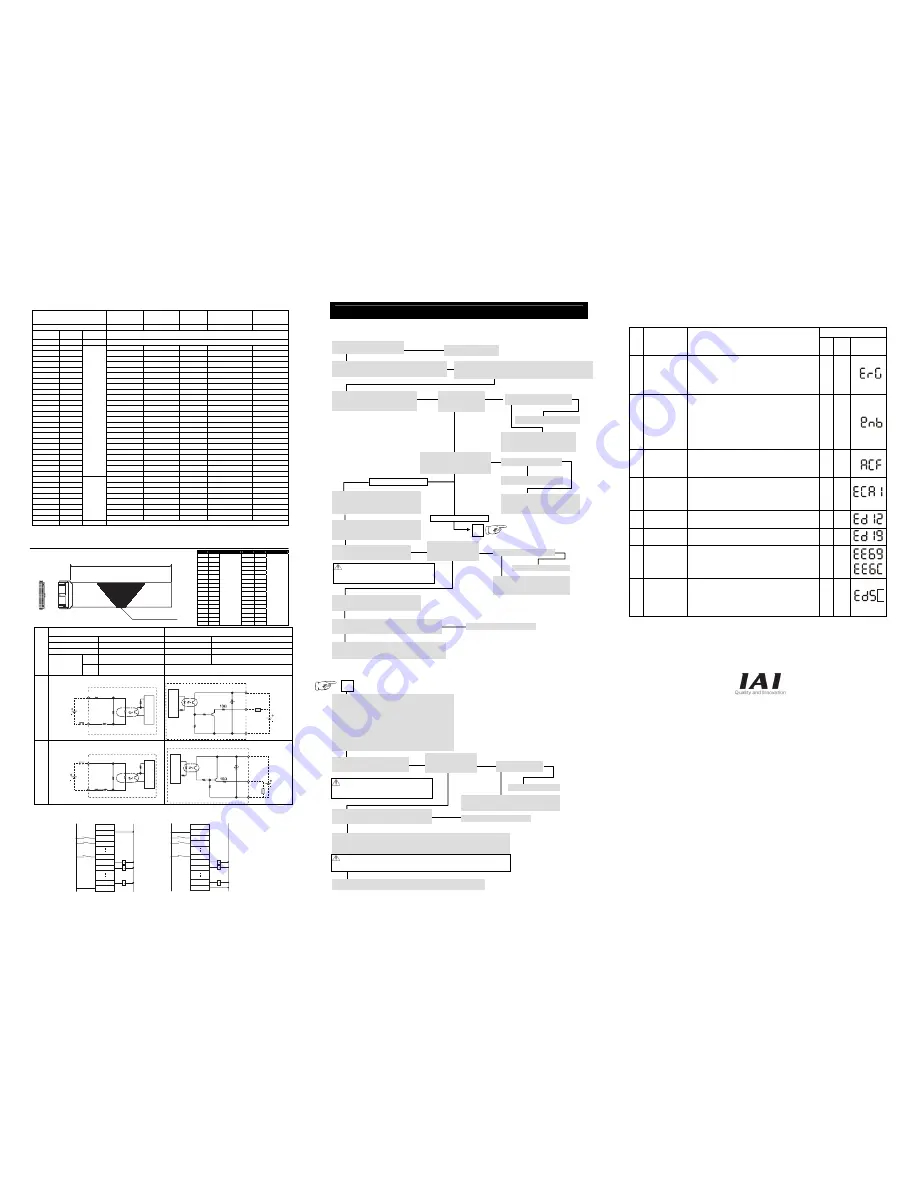

Mode

Standard

Mode

Item Change

Mode

Double Axis

Independent

Mode

Teaching

Mode

゙

DS-S-C1

Interchangeable

Mode

Other Parameter No. 25

1

2

3

4

16

Pin No.

Electric

wire color Category

1A BR-1

+24V

P24

1B RD-1

PC10

PC10

PC7

JOG1-

PC1000

2A OR-1

PC11

PC11

PC8

JOG2+

-

2B YW-1

PC12

PC12

PC9

JOG2-

-

3A GN-1

PC13

PC13 PC10

IC001

-

3B BL-1

-

PC14 PC11

IC01

-

4A PL-1

-

PC15 PC12

IC05

-

4B GY-1

-

PC16 PC13

IC1

-

5A

WT-1

RES RES

RES RES CPRES

5B BK-1

CSTR

CSTR CSTR1 CSTR/PWRT CSTR

6A BR-2

HOME

HOME HOME1

SON

STP

6B RD-2

SON

SON SON1

*STP

CANC

7A OR-2

PUSH

PUSH *STP1

PC1

LINE

7B YW-2

*STP

*STP *CANC1

PC2

PC1

8A GN-2

*CANC *CANC CSTR2

PC3

PC2

8B BL-2

LINE

LINE HOME2

PC4

PC4

9A PL-2

PC1

PC1 SON2

PC5

PC8

9B GY-2

PC2

PC2 *STP2

PC6

PC10

10A WT-2

PC3

PC3 *CANC2

PC7

PC20

10B

BK-2

PC4 PC4

PC1 PC8 PC40

11A

BR-3

PC5 PC5

PC2 PC9 PC80

11B RD-3

PC6

PC6

PC3

PC10

PC100

12A OR-3

PC7

PC7

PC4

PC11

PC200

12B YW-3

PC8

PC8

PC5

MODE

PC400

13A GN-3

Input

PC9 PC9

PC6

JOG1+ PC800

13B

BL-3

*ALM *ALM

*ALM *ALM ALM

14A

PL-3

RDY RDY

RDY RDY RDY

14B GY-3

PEND

PEND PEND1 PEND/WEND PEND

15A WT-3

HEND

HEND HEND1

HEND

-

15B BK-3

SVON

SVON SVON1

SVON

-

16A BR-4

PSED

PSED PEND2

TCMD

-

16B RD-4

SSER

SSER HEND2

SSER

SSER

17A OR-4

Output

ABER ABER

SVON2 ABER ABER

17B YW-4 0V

N

I/O

Flat cable

Model

CB-DS-PIO

□□□

Input section

Output section

Item Specification Item

Specification

Input voltage

DC24V ± 10%

Load voltage

DC24V

Input current

7mA

Peak load electric current

100mA/1 point 400mA/8 points *

1

NPN ON Voltage: MIN. DC16.0V

OFF Voltage: MAX. DC5.0V

Leakage Current

MAX. 0.1mA

S

pecification

ON/OFF

Voltage

PNP ON Voltage: MIN. DC8.0V

OFF Voltage: MAX. DC19.0V

*1 The total of lead current reaches max. 400mA every

8 ports from output port No. 300.

NPN

Controller

Internal

Power Source

P24

Input Terminal

680

Ω

3.3k

Ω

External

Power

Source

DC24V

±10%

N

Load

P24

Controller

Internal

Power Source

Output Terminal

External

Power

Source

DC24V

±10%

Surge Absorber

Surge Absorber

Surge Absorber

PNP

680

Ω

3.3k

Ω

N

Controller

Internal

Power Source

Input Terminal

External

Power

Source

DC24V

±10%

P24

N

Load

Controller

Internal

Power Source

Output Terminal

External

Power

Source

DC24V

±10%

Surge Absorber

Surge Absorber

Surge Absorber

The I/O circuit is an equivalent circuit expressing the logic.

NPN type

PNP type

Starting Procedures

When using this product for the first time, make sure to avoid mistakes and incorrect wiring by

referring to the procedure below.

Troubleshooting

The following alarm displays are frequently generated at the start-up operation. Process it referring to the following description.

Deal with each of them referring to the following table.

Status display

Code

Status contents

Cause and Remedy

LED

Personal

Computer

TB

Panel Unit

(Option)

EMG During

emergency-stop

It is not an alarm.

•

It is generated when the emergency stop switch in the

teaching pendant or the personal computer application

software is not cancelled. In such case, cancel it.

•

It is generated when the personal computer cable is not

connected to the emergency stop box.

•

Check the emergency stop circuit.

○

enb Safety gate remains

opening

Deadman switch

OFF

It is not an alarm.

•

It is generated when the system I/O ENB signal is opened.

Check the ENB signal. (It is generated when the safety gate

is open. Close the safety gate.)

•

It is generated when the AUTO/MANU switch has been set to

“MANU” and the personal computer or the teaching pendant

is not connected. Connect the personal computer or the

teaching pendant or set the AUTO/MANU switch to “AUTO”.

•

When the actuator is to be started up, hold the deadman

switch on the teaching pendant to turn it on.

ACF AC Power

Interruption

Momentary Power

Failure

Power Voltage Drop

It is generated when the power voltage is not supplied. It will be

generated, for example, in the case that the AC100V is supplied

to the controller with AC200V specified. Check the power

supply.

CA1 Absolute Data

Backup Battery

Voltage Error

It is caused when the battery is not attached or battery voltage

drops.

In the case of the actuator for the single-axis robots or

Cartesian robots with the absolute data specifications, it is

generated when the power is connected for the first time.

Perform the absolute reset.

○

D12 Encoder

Disconnection Error

It is generated when the cable is broken or the encode cable is

not connected to the controller. Check the wiring.

○

D19 Encoder Reception

Time Out

It is generated when the encoder is broken down, the cable is

broken or the encoder cable is not connected to the controller.

Check the wiring.

○

E69

E6C

24V I/O Error

DO output current

error

It is generated when the +24V power for I/O is not supplied.

Check the power supply.

(How to start up the controller without connecting the I/O 24V

power)

Set both the I/O parameter No. 10 to “0”.

○

D5

□

Field Bus Error

It is generated when the field bus link connection is not

established.

Check the link cable connection, I/O parameter and PLC

parameter settings.

(How to start up the controller without connecting the field bus)

Set both the I/O parameter No. 10 to “0”.

○

IAI America Inc.

Head Office: 2690W 237th Street Torrance, CA 90505

TEL (310) 891-6015 FAX (310) 891-0815

Chicago Office: 1261 Hamilton Parkway Itasca, IL 60143

TEL (630) 467-9900 FAX (630) 467-9912

Atlanta Office: 1220-E Kennestone Circle,Marrietta,GA 30066

TEL (678) 354-9470 FAX (678) 354-9471

website: www.intelligentactuator.com

IAI Industrieroboter GmbH

Ober der Röth 4, D-65824 Schwalbach am Taunus, Germany

TEL 06196-88950 FAX 06196-889524

* Enter the cable length (L) in

□□□

(up to 10m)

Example) 080=8m

No.

color

Wirings

No.

color

Wirings

1A BR-1

9B GY-2

1B RD-2

10A WT-2

2A OR-1

10B BK-2

2B YW-1

11A BR-3

3A GN-1

11B RD-3

3B BL-1

12A OR-3

4A PL-1

12B YW-3

4B GY-1

13A GN-3

5A WT-1

13B BL-3

5B BK-1

14A PL-3

6A BR-1

14B GY-3

6B RD-2

15A WT-3

7A OR-2

15B BK-3

7B YW-2

16A BR-4

8A GN-1

16B RD-4

8B BL-2

17A OR-4

9A PL-2

Flat cable

(Press

welding)

17B YW-4

Flat cable

(Press

welding)

Set-up for operation is completed. Perform the system operation adjustment.

Catalogue No.: ME0209-1A

2m

Flat cable AWG28

(34 conductors)

1A

1B

17A

17B

No

connector

1A

1B

2A

13A

13B

14A

17A

17B

0V +24V

Pin No.

Load

A

→

↓

Yes

Perform the absolute reset.

Confirm the alarm description in the window

of the personal computer or teaching

pendant, and deal with it.

(Refer to the “Treatments in Error Condition”)

In the case that it has been installed vertically, repeating the

servo turning ON/OFF, might lower the unit slightly due to the

weight of the unit itself. In such case, take care so that your

hand is not caught or the work is not damaged.

* The homing operation for the absolute type is not required.

Set-up for operation is completed. Set the position and start the program.

A

PIO Pattern Settings

Set the Other Parameter No. 25.

Setting Range 1: Standard Mode

2: Item Change Mode

3: Double-Axis Independent Mode

4: Teaching Mode

16: DS-S-C1 Interchange Mode

(Refer to the Instruction Manual for the details).

Set the safety speed.

When the machine is delivered from the factory, the safety speed is

set to 250mm/s using the Parameter No. 33 common to all axes.

Change it if necessary.

Connect the motor cable.

•

To ensure safety, it is recommended that safety speed be enabled during initial movements.

•

When the unit is installed vertically and the brake release switch is set to “RLS” side, the unit might

drop due to its own weight. In such case, take care not to catch your hand or damage the handle.

No

→

→

No

→

→

↓

Yes

↓

↓

Yes

↓

No

↓

Yes

↓

No

↓

Yes

↓

↓

↓

No

→

↓

Yes

↓

Yes

↓

↓

↓

No

→

↓

Yes

↓

→

No

→

No

→

↓

Yes

No

→

↓

Yes

↓

Yes

No

→

Contact the sales shop.

Point Check Item

•

Have you perform the frame grounding and protective grounding processing.

•

Has the noise countermeasure been taken?

Power Supply and Alarm Check

Connect the personal computer or teaching

pendant, set the AUTO/MANU switch to the

[MANU] side and inject the power.

Check Item 1

Is the LED indicator

[EMG] turned off on the

front panel?

When the USB port is used, is the

dummy plug inserted to connect?

Insert the dummy plug to connect.

Check Item 1

Are the LED Indications “PWR” and

“RDY” turned ON on the front panel?

Is the LED Indication “ALM” turned OFF?

Is the actuator for Absolute?

Confirm the emergency stop switch box

connection.

Confirm that the emergency stop switch

has been cancelled.

Installation and Wiring

Install the controller and actuator and perform wiring according

to the instruction manual and the contents in this book.

Check of Packed Items

Are there all the delivered items?

PIO Pattern Settings

When the other parameter No. 25 is not set to

“0”, set it to “0”.

(When the machine is delivered from the factory,

it is set to “0”).

Parameter Setting

Set the parameters including I/O parameter with

the personal computer or teaching pendant

operation.

Servo ON

Turn ON the servo motor with the personal

computer or teaching pendant operation.

Connect the motor cable.

When the alarm is output, deal with it after

confirming the alarm description, using the

personal computer or teaching pendant

operation.

Homing Execution

Home the actuator with personal computer or

teaching pendant operation.

Check of Safety Circuit

Check that the emergency stop circuit (or motor drive power

cutoff circuit) operates normally to turn off the servo.

Check the emergency stop circuit.

Confirming the operation of the actuator

Confirm that the full stroke operation is performed without any

trouble with the jog operation.

Has the motor cable connected?

Servo ON

Turn ON the servo motor with the personal

computer or teaching pendant operation.

Has the motor cable

connected?

Confirm the alarm description in the window of the

personal computer or teaching pendant, and deal with it.

(Refer to the “Treatments in Error Condition”)

Check the emergency stop circuit.

Check of Safety Circuit

Check that the emergency stop circuit (or motor drive-power

cutoff circuit) operates normally to turn off the servo.

Target Position Setting

Set a target position in the “Position” field for each position in the position table.

When carrying out direct teaching, perform home return operation first.

When the unit is equipped with the brake, move it after setting the brake release switch to “RLS” side.

Confirming the operation of the actuator

Confirm that the full stroke operation is performed without any trouble with the jog operation.

←

In the case of Program Mode:

In the case of Positioner Mode:

Check Item

Are the LED Indications

“SV1” and “SV2” for the

turned ON axes turned ON?

In the case that it has been installed vertically, repeating the

servo turning ON/OFF, might lower the unit slightly due to the

weight of the unit itself. In such case, take care so that your

hand is not caught or the work is not damaged.

Check Item

Are the LED Indications

“SV1” and “SV2” for the

turned ON axes turned ON?

1A

1B

2A

13A

13B

14A

17A

17B

0V

+24V

Pin No.

Load