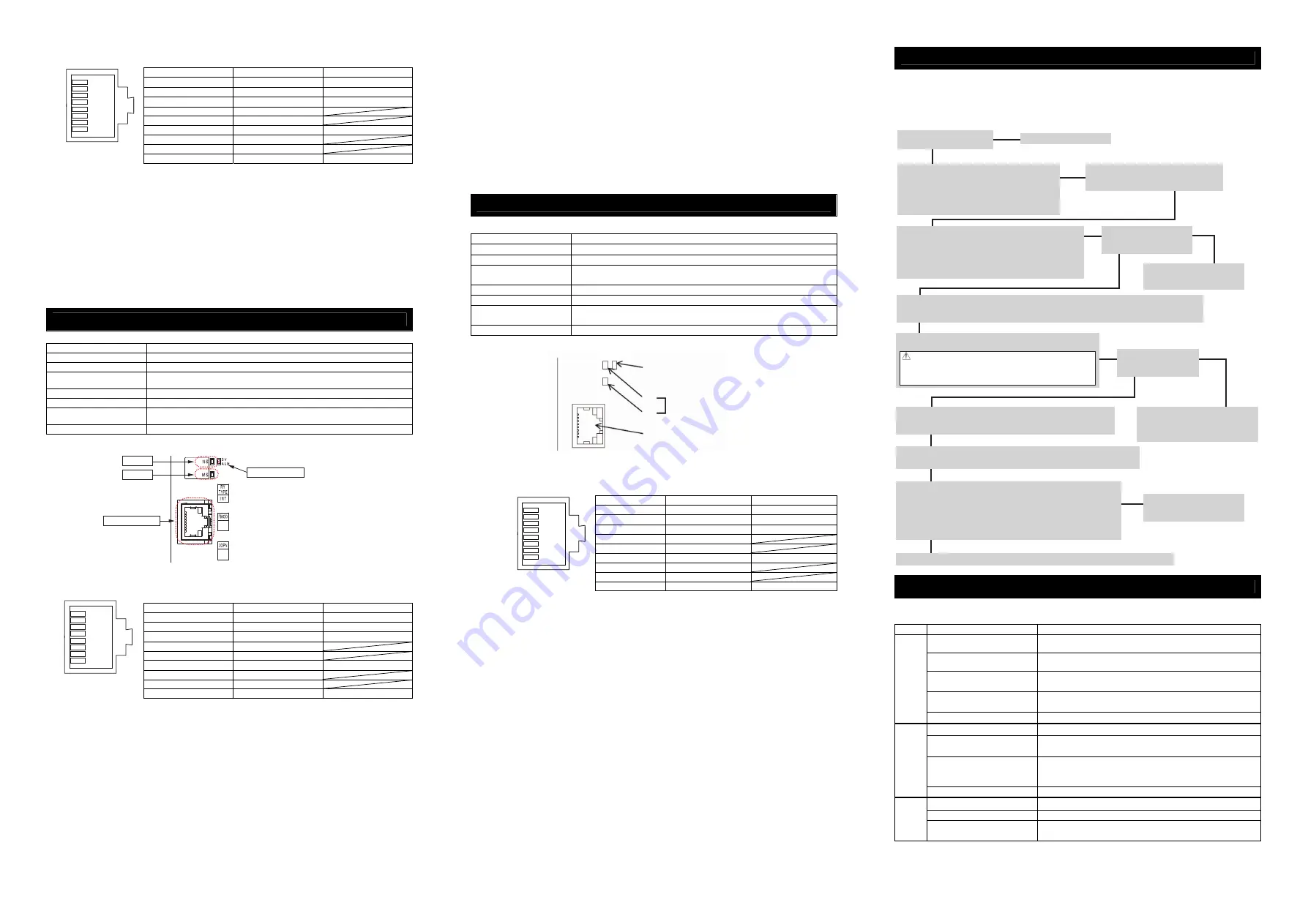

● EtherCAT® Connector

Pin No.

Signal Name

Abbreviated Code

1

Data s

TD

+

2

Data sending -

TD

−

3

Data rec

RD

+

4

Not used

5

Not used

6

Data receiving -

RD

−

7

Not used

8

Not used

Connector Hood

Security grounding

FG

● Operation Mode Setting and Address Allocation

The operation mode is set using the parameters.

Set the mode change switch on the controller front panel to “MANU” side and set the parameter No.84

“FMOD: Fieldbbus Operation Mode” using the teaching tool such as PC software for RC.

[Refer to the Instruction Manual for the details]

● Node address setting

Node address can be set with the parameter.

Set Parameter No.85 “NADR: Fieldbus Node Address” with a teaching tool such as PC software for RC.

Settable Range: 0 to 127 (It is set to 17 which is the I/O slave top address of EtherCAT® at the delivery.)

● Communication Speed Setting

The setting for the communication speed is not required because it automatically follows the master’s

communication speed.

(Note) After parameter setting, reset the controller mode change witch to “AUTO” side, and then cycle the controller power.

EtherNet/IP

● Specification

Item

Specification

Communication Protocol

IEC61158 (IEEE802.3)

Communication Speed

10BASE-T/100BASE-T (Autonegotiation setting is recommended)

Communication Cable Length

Depends on EtherNet/IP Type

(Distance between hub and each node: 100m max.)

Number of Connection

Depends on the master unit

Applicable Node Address

0.0.0.0 to 255.255.255.255

Communication Cable

Category 5 or more

(Double shielded cable braided with aluminum foil recommended)

Connector

RJ45 Connector

×

1pc

● Interface Section

(Note) Refer to the troubleshooting or the Instruction Manual for the details of LED displays.

● EtherNet/IP Connector

Pin No.

Signal Name

Abbreviated Code

1

Data s

TD

+

2

Data sending -

TD

−

3

Data rec

RD

+

4

Not used

5

Not used

6

Data receiving -

RD

−

7

Not used

8

Not used

Connector Hood

Security grounding

FG

● Operation Mode Setting and Address Allocation

The operation mode is set using the parameters.

Set the mode change switch on the controller front panel to “MANU” side and set the parameter No.84

“FMOD: Fieldbus Operation Mode” using the teaching tool such as PC software for RC.

[Refer to the Instruction Manual for the details]

● Communication Speed Setting

The Communication speed can be set with the parameter. A special setting is not necessary since it is set

to automatic negotiation when the product is delivered. However, when a fixed speed is required, change

the setting to the desired speed in Parameter No.86 “FBRS: Fieldbus Communication Speed” of the

teaching tool in the PC software for RC.

[Refer to the Instruction Manual for the details]

● IP Address Setting

IP Address can be set with the parameter.

Set Parameter No.140 “IPAD: IP Address” with a teaching tool such as PC software for RC.

Settable Range: 0.0.0.0 to 255.255.255.255 (It is set to “192.168.0.1” when the machine is delivered from

the factory.)

● Settings for Subnet Mask

Subnet Mask can be set with the parameter.

Set Parameter No.141 “SNMK: Subnet Mask” with a teaching tool such as PC software for RC.

Settable Range: 0.0.0.0 to 255.255.255.255 (It is set to “255.255.255.0” when the machine is delivered

from the factory.)

● Settings for Default Gateway

Default Gateway can be set with the parameter.

Set Parameter No.142 “DFGW: Default Gateway” with a teaching tool such as PC software for RC.

Settable Range: 0.0.0.0 to 255.255.255.255 (It is set to “0.0.0.0” when the machine is delivered from the

factory.)

(Note) After parameter setting, reset the controller mode change witch to “AUTO” side, and then cycle the controller power.

PROFINET-IO

● Specification

Item

Specification

Communication protocol

IEC61158 (IEEE802.3), IEC61748

Communication Speed

100Mbps

Communication cable length

Depends on PROFINET-IO Specification

(Distance between each segment: 100m Max.)

Number of Connection

Depends on the master unit

Applicable node address

0.0.0.0 to 255.255.255.255

Communication cable

Category 5 or more

(Double shielded cable braided with aluminum foil recommended)

Connector

RJ45 Connector

×

1pc

● Interface Section

(Note) Refer to the troubleshooting or the Instruction Manual for the details of LED displays.

● EherNet/IP Connector

Pin No.

Signal Name

Abbreviated Code

1

Data sending

+

TD

+

2

Data sending

−

TD

−

3

Data receiving

+

RD

+

4

Not used

5

Not used

6

Data receiving

−

RD

−

7

Not used

8

Not used

Connector Hood

Security grounding

FG

● Operation Mode Setting and Address Allocation

The operation mode is set using the parameters.

Set the mode change switch on the controller front panel to “MANU” side and set the parameter No. 84

“FMOD: Field Bus Operation Mode” using the teaching tool such as PC software for RC.

[Refer to the Instruction Manual for the details]

● Communication Speed Setting

It is not necessary to establish setting. It is fixed at 100Mbps.

● Node address setting

It is not necessary to establish setting on the IAI controller side as it should be established on the master

side.

(Note) After parameter setting, reset the controller mode change witch to “AUTO” side, and then cycle the controller power.

Starting Procedure

When using this product for the first time, make sure to avoid mistakes and incorrect wiring by referring to

the procedure below.

This section explains how to start up an EtherCAT®, EtherNet/IP and PROFINET-IO complaint PCON,

ACON and DCON (described as the “controller” in the following diagram). For the settings and wiring of each

of the individual devices, controllers, and actuators connected to the network, refer to the individual device’s

Instruction Manual.

Trouble Shooting

If an error has occurred, it is possible to check the operation condition on the status LEDs on the front panel.

● Status LED Displays of EtherCAT® Type

{

: Illuminating,

×

: OFF,

☆

: Flashing

Name

Indication Color

Description

×

Initial condition (EtherCAT® communication in “INIT” condition) or the

power is OFF

{

(GN)

In normal operation (EtherCAT® communication in “OPERATION”

condition)

☆

(GN)

(ON: 200ms/OFF: 200ms)

(EtherCAT® communication in “PRE-OPERATION” condition)

☆

(GN)

(ON: 200ms/OFF: 1000ms)

(EtherCAT® communication in “SAFE-OPERATION” condition)

RUN

{

(OR)

Communication component (module) error

×

No abnormality or the power is OFF

☆

(OR)

(ON: 200ms/OFF: 200ms)

Construction information (settings) error

(Information received from the master cannot be set)

☆

(OR)

(ON: 200ms

×

2 times/

OFF: 1000ms)

Communication section circuit error

(Watchdog timer timeout)

ERR

{

(OR)

Communication component (module) error

×

Link status not detected or the power is OFF

{

(GN)

Linked (No network congestion)

Link/

Activity

☆

(GN)

(ON: 50ms/OFF: 50ms)

Linked (Network in congestion)

1

8

RJ45 8-pin

Modular Connector

(Controller side)

1

8

RJ45 8-pin

Modular Connector

(Controller side)

NS LED

MS LED

EtherNet/IP Port

Status LED

Status Diplay LED

Check of Packed Items

Has everything been received?

Installation and Wiring

Follow Instruction Manual and this manual to install the

controller and connect to the network.

Also, perform the wirings of the motor and encoder

cables for the power supply unit and the actuators

following the Instruction Manual of each controller.

To turn ON the controller

1) Set the mode switch on the front panel to MANU side.

2) Set the brake release switch on the front panel to NOM side.

3) Connect a teaching tool such as the PC software.

4) Turn the power ON and start up the teaching tool with

“Teaching Mode Safety Speed Valid” setting.

Controller Initial Settings

Refer to each fieldbus section to perform the necessary parameter settings of the modes, addresses, etc.

• Set Parameter No.35 Safety Speed if necessary. [Initial Value: 100mm/s]

Servo ON

Turn the servo ON by operating the teaching tool.

Contact us or our distributor.

Point Check Item

• Is frame ground (FG) connected?

• Has the noise countermeasure been taken?

Important Check Item

Is the status display LED on

the front panel turned OFF?

Check the detail of the alarm on

the teaching tool and remedy

any errors.

Yes↓

No↓

→

→

No→

↓Yes

←Yes

↓

↓

Note (In the case that the actuator is in vertical mount)

When the machine is turned ON/OFF repeatedly at the same

position, the actuator position may lower slightly due to its own

weight. Take care not to catch your hand or damage the work.

Check of Safety Circuit

Check that the emergency stop circuit (or motor drive-power cutoff circuit)

operates normally to turn OFF the servo.

Important Check Item

Is the status display LED

turned ON in green?

If an alarm is generated (status display

LED is ON in red), check the detail of

the alarm on the teaching tool and

remedy any errors.

Settings on Host System

Refer to PLC Instruction Manual to perform the communication settings and so on.

Refer to the Instruction Manual

for each unit, controller and PLC

to check each setting.

No↓

Yes↓

↓Yes

↓

↓

→

No→

Communication is now established. Perform an operation check and adjustment for the system.

Confirming Communication Establishment

• Confirm the communication is established on the status LED on the front

panel. [Refer to the troubleshooting]

• Is the LED status in normal condition? Is PLC (master unit) side also

in normal condition?

(Note) Refer to PLC and master unit Instruction Manuals for how to check

the master unit side.

1

8

RJ45 8-pin

Modular Connector

(Controller Side)

PROFINET-IO Port

NS

MS

Monitoring LED

SV/ALM Status Display LED