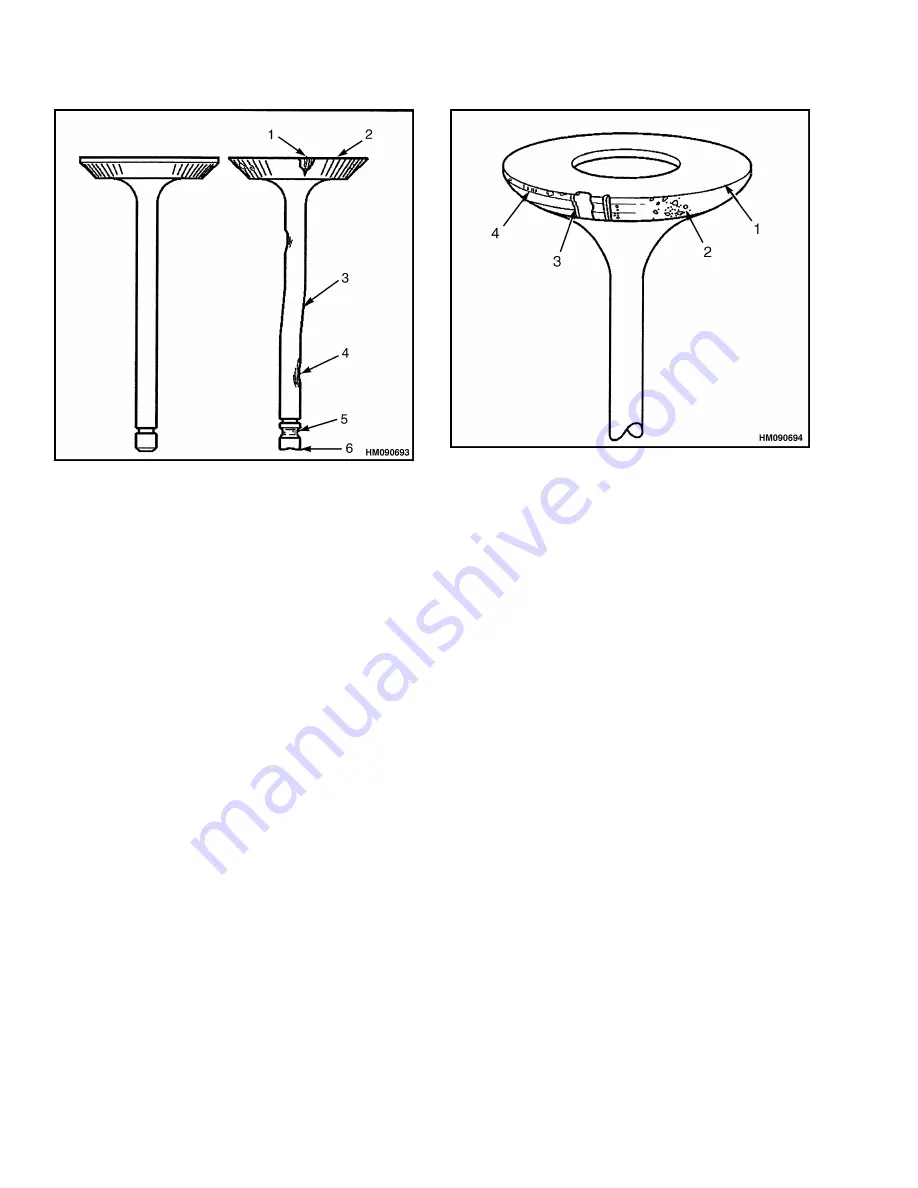

1. BURNT OR DAMAGED AREAS

2. UNDERSIZED MARGIN

3. BENT STEM

4. SCORING/DAMAGE TO THE STEM

5. WORN KEY GROOVE

6. WORN STEM TIP

Figure 7. Valve Inspection

Valve stems with excessive guide clearance must

be repaired or replaced. Refer to Engine Specifi-

cations.

8.

Inspect valve contact surface for the following:

• Undersized margin

• Pitted surface

• Burnt or eroded areas

• Acceptable edge margin

Valves with excessive damage must be replaced.

Minor imperfections of valve or valve seat may

be repaired. Refer to Valve Guides and Seats,

Repairs or Valves, Repair.

VALVE OIL SEALS

The following procedure addresses replacement of

valve oil seals. If ONLY valve oil seals are being re-

placed, it is not necessary to remove the cylinder

head.

1. UNDERSIZED MARGIN

2. PITTED SURFACE

3. BURNT OR ERODED AREAS

4. ACCEPTABLE EDGE MARGIN

Figure 8. Valve Contact Surface Inspection

Remove and Disassemble

1.

Remove spark plug wires from spark plugs and

position spark plug wires out of way.

2.

Remove each spark plug and spark plug wire

shield.

NOTE:

If spark plugs are not being replaced label

each spark plug to its corresponding cylinder.

3.

Remove rocker cover bolts and grommets. Dis-

card grommets. Repeat for other rocker cover.

4.

Remove rocker covers. Disconnect the Positive

Crankcase Ventilation valve from the air inlet

hose.

5.

Perform cylinder leak down test for each cylin-

der. See Cylinder Leak Down Test.

6.

Remove valve rocker arms. Organize rocker

arms so they can be installed in their original

positions. Repeat for other side.

Cylinder Head Repair

0600 SRM 1251

6