MAINTENANCE

82

CAUTION

Check all wheel nuts after 2 to 5 hours of operation:

when new lift trucks begin operation and on all lift

trucks when the drive wheels have been removed and

installed. Tighten the nuts in a cross pattern to the

correct torque value shown in the MAINTENANCE

SCHEDULE. When the nuts stay tight for eight hours,

the interval for checking the torque can be extended

to 350 hours.

Forks

The identification of a fork is how the fork is connected to

the carriage. The

H70--110XL

series of lift trucks normally

have a hook fork. A pin fork is available for this series of

lift trucks as an option. The

H135--155XL

series of lift

trucks normally have a pin fork.

Forks, Adjustment

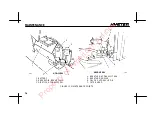

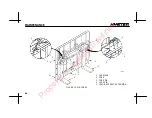

Hook forks

are connected to the carriage by hooks and

lock pins. The lock pins can be one of two types. See

FIGURE 18. These lock pins are installed through the top

fork hooks and fit into slots in the top carriage bar. Adjust

the forks as far apart as possible for maximum support of

the load. Hook forks will slide along the carriage bars to

adjust for the load to be carried. Raise the lock pin in each

fork to slide the fork on the carriage bar. Make sure the

lock pin is engaged in the carriage bar to lock the fork in

position after the width adjustment is made.

Property of American Airlines