17

MAINTENANCE

Fig. 15

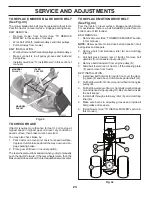

Fig. 16

TRACTOR

Always observe safety rules when per form ing any

main te nance.

BRAKE OPERATION

If tractor requires more than five (5) feet (1,5 m) to stop at

highest speed in high est gear on a level, dry concrete or

paved surface, then brake must be checked and ad just ed.

(See “TO CHECK BRAKE” in the Ser vice and Ad just ments

section of this manual.)

TIRES

•

Maintain proper air pressure in all tires. (See the sides

of tires for proper PSI.)

• Keep tires free of gasoline, oil, or insect control

chemi cals which can harm rubber.

• Avoid stumps, stones, deep ruts, sharp objects and

other hazards that may cause tire damage.

NOTE:

To seal tire punctures and pre vent flat tires due

to slow leaks, tire sealant may be purchased from your

local parts dealer. Tire sealant also pre vents tire dry rot

and corrosion.

OPERATOR PRESENCE SYS TEM AND REVERSE

OPERATION SYSTEM (ROS) (See Fig. 15)

Be sure operator presence and reverse operation sys tems

are work ing properly. If your tractor does not function as

described, repair the problem immediately.

• The engine should not start unless the brake pedal is

fully de pressed, and the attachment clutch con trol is

in the dis en gaged position.

CHECK OPERATOR PRESENCE SYSTEM

•

When the engine is running, any attempt by the op er a tor

to leave the seat without first setting the parking brake

should shut off the engine.

•

When the engine is running and the at tach ment clutch

is engaged, any attempt by the operator to leave the

seat should shut off the engine.

• The attachment clutch should never operate unless

the operator is in the seat.

CHECK REVERSE OPERATION (ROS) SYSTEM

• When the engine is running with the ignition switch in

the engine "ON" position and the at tach ment clutch

engaged, any attempt by the operator to shift into

reverse should shut off the engine.

• When the engine is running with the ignition switch

in the ROS "ON" position and the at tach ment clutch

engaged, any attempt by the operator to shift into

reverse should NOT shut off the engine.

BLADE CARE

For best results mower blades must be kept sharp. Re place

bent or damaged blades.

BATTERY

Your tractor has a battery charging system which is suf fi cient

for normal use. However, periodic charging of the battery

with an automotive charger will extend its life.

• Keep battery and terminals clean.

• Keep battery bolts tight.

• Keep small vent holes open.

• Recharge at 6-10 amperes for 1 hour.

NOTE:

The original equipment battery on your tractor is

maintenance free. Do not attempt to open or remove caps

or covers. Adding or checking level of electrolyte is not

necessary.

TO CLEAN BATTERY AND TERMINALS

Corrosion and dirt on the battery and terminals can cause

the battery to “leak” power.

• Remove terminal guard.

•

Disconnect BLACK battery cable first then RED bat tery

cable and remove battery from tractor.

• Rinse the battery with plain water and dry.

•

Clean terminals and battery cable ends with wire brush

until bright.

• Coat terminals with grease or petroleum jelly.

•

Reinstall battery. (See “REPLACING BATTERY" in the

Service and Adjustments section of this manual.)

BLADE REMOVAL (See Fig. 16)

• Raise mower to highest position to allow access to

blades.

NOTE:

Protect your hands with gloves and/or wrap blade

with heavy cloth.

• Remove blade bolt by turning counterclockwise.

•

Install new or resharpened blade with stamped "GRASS

SIDE" facing the ground.

IMPORTANT:

To ensure proper assembly, center hole in

blade must align with star on mandrel assembly.

• Install and tighten blade bolt securely (45-55 Ft. Lbs./

62-75 Nm).

IMPORTANT

: SPECIAL BLADE BOLT IS HEAT TREATED.

ROS "ON"

POSITION

ENGINE "ON" POSITION

(NORMAL OPERATING)

CAUTION: Use only a replacement blade ap-

proved by the manufacturer of your tractor.

Using a blade not approved by the manu-

facturer of your tractor is hazardous, could

damage your tractor and void your warranty.

BLADE

BLADE

BOLT

(SPECIAL)

CENTER

HOLE

STAR

MANDREL

ASSEMBLY

Summary of Contents for LT19538R

Page 30: ...30 SERVICE NOTES ...

Page 32: ...06 05 2013 TH ...