24

TROUBLE SHOOTING

PROBLEM

POSSIBLE CAUSES

ENGINE WILL NOT START.

Blade switch on.

Drive levers not in the neutral slots.

Operator not in seat.

Park brake disengaged.

Dead battery.

Fuel valve closed or in the wrong position.

No fuel.

Spark plugs defective.

Spark plug wires off.

MACHINE WILL NOT MOVE OR MOVES

SLOWLY OR HARD.

Park brake on.

Pump bypass valves open.

Pump drive belt loose or off.

Hydraulic system failure.

Air in the hydraulic system.

BLADES WILL NOT ENGAGE.

Blade belt off.

Clutch unhooked form wiring harness.

Blade switch failure or unhooked from harness.

Fuse burnt out.

UNEVEN CUT

Tire pressure uneven.

Blades bent.

Deck chains uneven.

Deck lift blocks loose.

Anti-scalp rollers set uneven.

CUT IS RAGGED

Blades dull.

Ground speed to fast.

Grass to long.

Grass accumulation under deck.

MACHINE VIBRATION

Blades loose.

Blades unbalanced.

Engine loose from mounts.

Summary of Contents for 968999185

Page 2: ...2 2003 Husqvarna All rights reserved Beatrice NE Printed in U S A ...

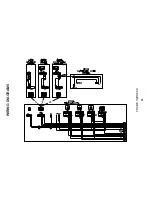

Page 26: ...26 WIRING DIAGRAMS CONSOLE HARNESS SCHEMATIC ...

Page 28: ...28 WIRING DIAGRAMS FRAME HARNESS ...

Page 29: ...29 ...

Page 30: ......