Room Thermostat

High Limit

Thermostat

90°C

Circulating Pump

Low Limit Thermostat (45°C)

Time Switch

Drain Cock

Room Thermostat

High Limit

Thermostat

90°C

Circulating Pump

Low Limit Thermostat (45°C)

Time Switch

Drain Cock

Injector Tee

Wiring Diagram for general guidance only

All electrical work must be carried out by a competent

electrician in accordance with the rules in force and the

instructions provided by the circulating pump and

heating controls manufacturer

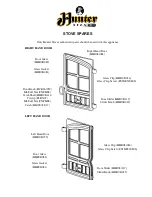

Two Tapping System

Four Tapping System