6

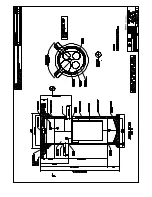

JellyFish® filter

Flow into the lower chamber must then pass tangentially

around the separator skirt protecting the cartridges

and increasing the flowpath length. Coarse sediment

settles out of the MAW zone into the sump. As water

flows tangentially around the separator skirt in the

lower chamber, the large opening in the bottom of the

separator skirt and upward change in direction further

reduces flow velocity and enhances particle separation.

As a result, sediment settles in the sump.

Flows pass through the cartridge in the filtration zone.

Each filter cartridge consists of multiple tentacles.

Hydraulic pressure across the entire membrane surface

area causes water to penetrate the filtration tentacles.

Water enters the membrane pores radially and deposits

fine particulates on the exterior membrane surface.

Filtered water flows into the centre drain tube of each

tentacle, the water then flows upward and out the top.

Water exiting the top of the tentacles combines under

the lid, where the combined flow exits the cartridge

through the orifice with a pulsating fountain effect

into the backwash pool. When the water level in the

backwash pool exceeds the weir height it overflows to

the outlet pipe.

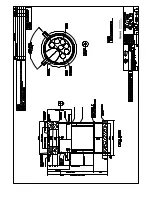

Outside the backwash pool, the draindown cartridge

provides treatment at a reduced flow rate (2.5 L/s) and

allows the treated water captured in the backwash pool

to return through the cartridges and balance water

pressure as the storm event ends.

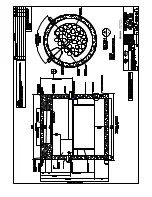

As particles build up on the external membrane

surface, the pores progressively become smaller. This

process, referred to as “filter ripening”, significantly

improves the removal efficiency relative to a brand

new or clean membrane. Filter ripening accounts for

the ability of the JellyFish® filter to remove particles

finer than the nominal pore size (20 microns) rating

of the membranes. An animation of the JellyFish®

filter operation and maintenance is available at

humeswatersolutions.com.au.

Self-cleaning functions

The JellyFish® filter utilises several self-cleaning

processes to remove accumulated sediment from the

external surfaces of the filtration membranes, including

automatic backwash of the high-flow cartridges,

vibrational pulses, and gravity. These processes have

been confirmed by more than 12 months of full

scale prototype testing. Combined, these processes

significantly extend the cartridge life, maintenance

interval and reduce life-cycle costs.

Automatic backwash occurs with the high-flow

cartridges at the end of each runoff event. This can occur

multiple times during a single storm event as intensity

and driving head varies. As the inflow subsides and

driving head decreases, water in the backwash pool

reverses flow direction and automatically backwashes

the high-flow cartridges, removing sediment from the

membrane surfaces. Water in the lower chamber (below

deck) is displaced through the draindown cartridges.

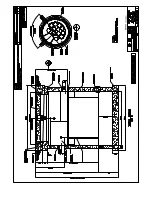

Vibrational pulses occur as a result of complex and

variable pressure and flow direction conditions that

arise in the deck during operation. During forward flow

a stream of filtered water exits the top of each filtration

cartridge and encounters resistance from the turbulent

pool of water in the backwash pool. Water is forced

through the cartridge lid orifice into the backwash pool

with a pulsating fountain effect. The resulting pulses

transmit vibrations through the deck to the membranes,

thereby dislodging accumulated sediment. The effect

is pronounced at higher flow rates, and influences

all cartridges.

Accumulated sediment on the membranes will settle

under gravity both during inflow events and inter-event

dry periods. As fine particles form into larger masses

on the membrane surface, adhesion to the membrane

surface lessens, and sediment sheds away from the

membrane. Chemical processes and biofilm effects also

play a role.