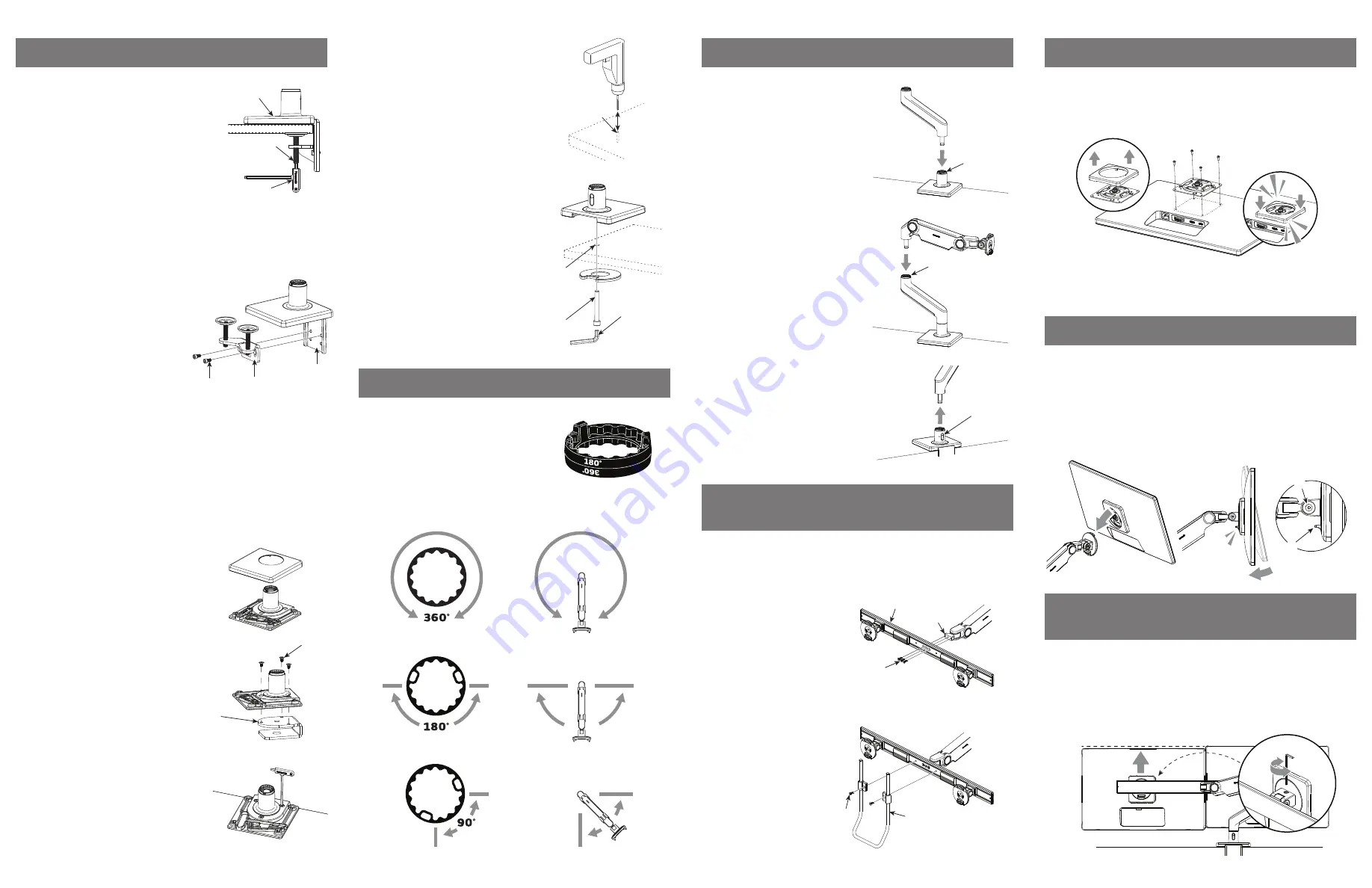

STEP 5: ATTACH VESA BRACKET TO MONITOR

STEP 7: LEVELING THE MONITORS

(DUAL-MONITOR APPLICATION ONLY)

STEP 6: ATTACH MONITOR TO ARM

A

B

1. Hold the monitor angled back and lower it onto the arm. Fit the hook at the top

of the arm into the corresponding cutout in the VESA Bracket.

2. Tilt the monitor back upright until the Quick Release Tab (B) on the arm

snaps into position.

3. To remove the monitor, lift the Quick Release Tab and pull the bottom of the

monitor away from the arm, then lift free of the hook.

NOTE

: If needed, adjust the tension screw (A) to hold the monitor in position.

After the monitors are installed on the crossbar, there may be a small height difference

between them. To align the monitors, use the adjustment screw located on top of the

monitor tilt.

1. To raise a monitor, turn the screw clockwise. To lower, turn counter clockwise.

2. If the adjustment bottoms out before reaching alignment, move the second

monitor in the opposite direction.

1. Separate the VESA cover from the VESA bracket.

2. Position the VESA Bracket over the mounting holes on the back of monitor with the

D-shaped cutouts in a vertical orientation. Attach using the 4 VESA screws provided.

3. Snap the VESA cover back in place.

The VESA Bracket features 75mm and 100mm hole patterns.

If you need to offset the Bracket from the monitor use the provided Extended VESA

screws and Plastic Spacers. You may also use the screws that came with your monitor.

STEP 3: ATTACH ARM TO BASE STEM

If using dual monitors, attach the crossbar according to the following steps. If using

triple monitors, use the instructions included with the triple crossbar. If using a single

monitor, continue to Step 5.

STEP 4: ATTACH CROSSBAR TO ARM

(DUAL-MONITOR APPLICATION ONLY)

2. (Optional) Attach handle (D) to

crossbar by using included

screws (E). Adjust the handle to

desired height. Tighten with

4mm hex key until secure.

1. Attach crossbar (A) to crossbar

link (B) using crossbar link

screws (C). Tighten with 4mm

hex key until secure.

NOTE

: Before adding each link, adjust the

smart stop (A) according to step 2. If using a

3 link configuration, one of the links must be

a 4” link. The link installation order may need

to be swapped so as to comply with step 2.

1. Insert the angled link into the mount

until release button locks in place.

2. Insert the dynamic link into the

angled link until the release button

locks in place.

3. To remove links, press the release

button (B) and lift upward near the joint.

A

B

C

E

D

A

A

B

J

K

L

BOLT-THROUGH MOUNT

1D. For installation on work surface with no

access for clamp system:

i. Drill 1/2" hole through work surface in

desired location.

NOTE:

Bolt-Through Mount can accommodate

a hole up to 4” (102mm) in diameter. If hole

is 2” (51mm) or more, cables can be routed

through the hole. For some 2”grommet

holes, cables should be routed before

installation of mount to accommodate cable

plugs (cable access is approximately 1.5” x

0.25” with 2” grommets).

ii. Position the M10 Base over the work

surface hole (J).

iii. Align Bolt-Through Plate, foam side up,

under the work surface. Pass the Bolt (K)

through the hole in the plate and screw

into M10 base by using 8mm hex key (L).

J

STEP 2: SMART STOP ADJUSTMENT

In each arm connection, there is an adjustable Smart

Stop Ring which can be positioned to limit the arm’s

range of motion. Depending on the orientation of the

ring the arms can be set to rotate either 90°, 180°,

or 360°. The marked angle will be in the center of

the range of motion. The stop rings must be

configured in such a way that the dynamic link head

does not pass behind the rear edge of the unit.

Arm can rotate

without stopping

Arm can rotate 180˚

Arm can rotate 90˚

STEP 1: ATTACH MOUNT TO WORK SURFACE

CLAMP MOUNT

NOTE:

There are two sets of Bracket Screw

holes to accommodate the thickness of every

work surface. Use the upper holes for surfaces

up to 1.8” (48mm) thick and lower holes for

surfaces up to 2.7” (68mm) thick.

1A. For installation on open edge of

work surface:

i.

Slide Mount (A) against work surface

edge and fully tighten Clamp screws(B)

with 5mm hex key (C).

1B. For installation on work surface

positioned against a wall or panel:

NOTE:

This method can also be used to

mount through grommet holes wider than 3”

i. Detach the Bottom Clamp (D) from the Top

Bracket (E) by loosening Bracket Screws

(F) with 5mm hex key.

ii. Position the Top Bracket against work

surface edge.

iii. Underneath the work surface, reattach

the Bottom Clamp to the Top Bracket

using the Bracket screws.

iv. Fully tighten the Clamp Screws (G) with

5mm hex key.

NOTE:

Clamp Mounts cannot be used to

mount the M10 to any vertical surface.

SLIDING DESK MOUNT

1C. For installation on a desk with minimal

clamp clearance:

i. Remove Base Cover.

ii. Loosely attach Clamp Bracket (H) to base

with three included screws (I). The screws

should not be tightened all the way.

iii. Slide the base and clamp over the back

edge of the work surface until the clamp

rests on the edge.

iv. Fully tighten the three clamp screws to

secure the base to the work surface.

A

B

C

F

D

E

H

I