Chapter

4---Maintenance

(Removal/Replacement)

7. Place the Green CRT Assembly in a safe location on or

against one of the other CRT Assemblies.

8. Disconnect the Red and Blue CRT Socket Connectors

and gently lay them on the top of the Video Amplifier

Board.

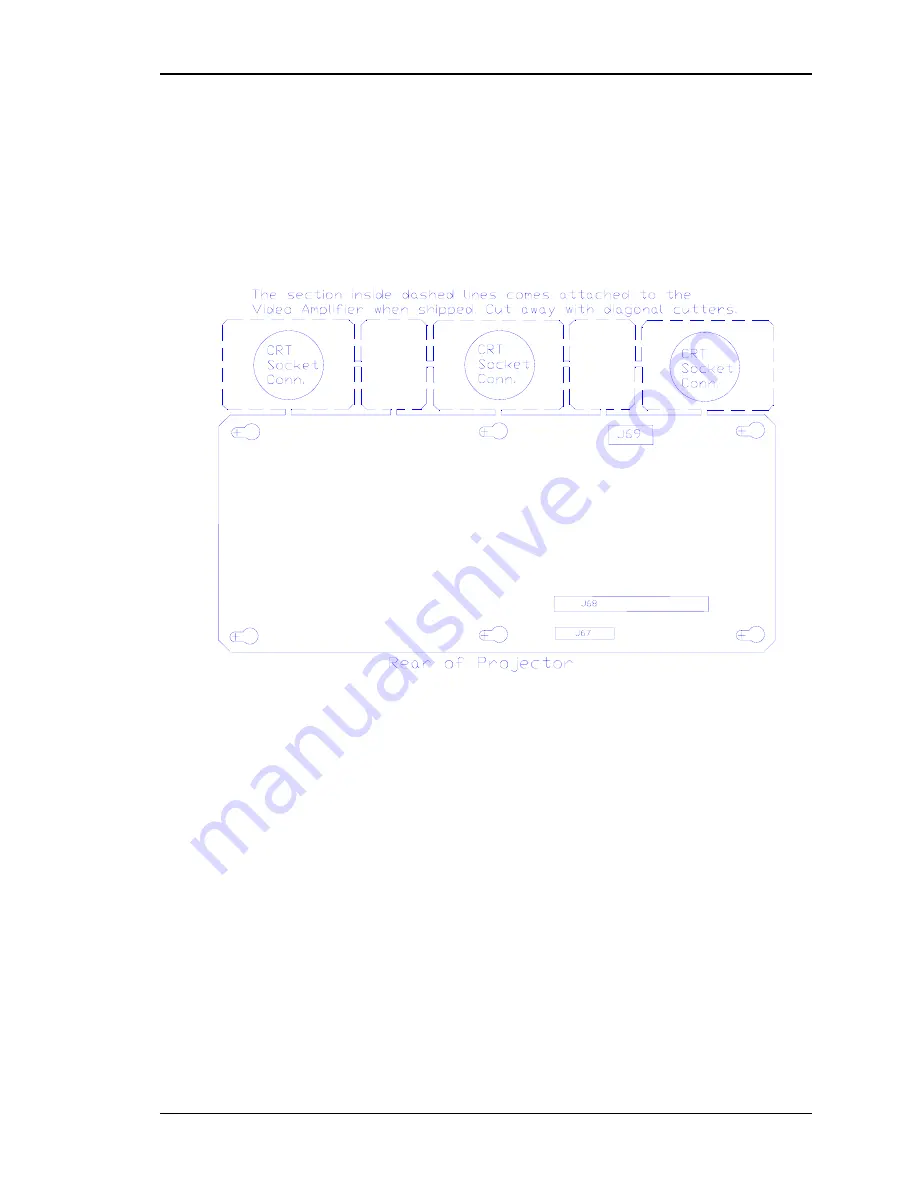

9. Disconnect the 3 connectors (push in slightly, squeeze

the tabs, and pull out), J67, J68, and J69 from the Video

Amplifier PCB. Move the cables out of the way.

Figure 4-9.

Video Amplifier PCB showing breakaway CRT Socket

Connectors.

10. Disconnect the 3 Focus cables that run from the CRT

Socket Connectors to the Focus connectors on the

HVPS.

NOTE:

Observe that each of the 3 Focus cables

(large, red wires that run from each CRT Socket

Connector to the Focus connectors on the HVPS) is

joined near the CRT by a coupler plug and jack.

Disconnect (and label) the focus cables at these couplers.

11. Loosen the 6 pozidrive screws that secure the Video

Amplifier PCB to the projector frame.

12. Make sure everything is out of the way, then slide the

Video Amplifier PCB toward the left so the mounting

screws will clear the access holes and remove the board

from the projector.

13. Reinstall in the reverse order from above.

NOTE:

The

Video Amplifier PCB is shipped with the 3 CRT Socket

Connectors attached at the end in a “breakaway”

arrangement (

Figure 4-9

). Use a pair of diagonal cutters

Model 200 Service Manual

4-15

Summary of Contents for 200

Page 1: ...SERVICE MANUAL Model 200 Projector ...

Page 10: ...Safety Information Model 200 Service Manual x ...

Page 14: ...Chapter 1 Introduction 1 4 Model 200 Service Manual ...

Page 79: ...Chapter 2 System Description Model 200 Service Manual 2 65 ...

Page 121: ...Chapter 4 Maintenance Removal Replacement 4 24 Model 200 Service Manual ...

Page 131: ...Chapter 5 Troubleshooting 5 10 Model 200 Service Manual ...