6

A.

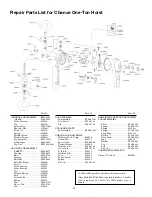

Handle Sub-Assembly

(E309-

0819 & Related Parts) All handles

marked with Part No. "19671", no

revision letter or "19671-F" should

be replaced with E309-0819 because

of possible part interchangeability

problems.

(1) Examine "stop surfaces for

impact damages caused by

such improper practices as al-

lowing handle to self-ratchet,

and "slamming" the handle

unnecessarily during use.

Refer to fig. 1.

Excessive battering and sub-

sequent eroding, of the "stop"

surfaces, on both the handle

and housing, can cause shear-

ing of the housing spring

retaining screw (56163). As

the surfaces are eroded away,

the clearance between the

tip of the unloader plate and

the screw is reduced enough

to allow the unloader plate to

strike the screw. Refer to Fig.

2. Screw shearing, can also

occur if the hoist is allowed to

"self-ratchet", the momentum

of the unloader plate can cause

it to exceed its normal amount

of travel and strike the spring

screw.

(2) Handle damage caused by ap-

ply "cheaters" (extensions) to

increase leverage and other

improper practices is quite com-

mon on hoists returned to the

factory for repair. Such hoists

may have been dangerously

overloaded as a result of such

usage. Any hoist exhibiting

evidence of this type of treat-

ment, and even undamaged

hoists, should be most care-

fully examined—particularly

the principle load carrying

members. The holding and

working dog assemblies (pawls)

must be checked and replaced

if they show any evidence of

creasing, chipping, or cracking.

The ratchet teeth on the forged

heat treated shaft (P309-0791)

must be checked for missing or

damaged teeth, and replaced

if necessary. Refer to Fig. 3

& 10.

(3) The handle dog (pawl) should

be examined for damage as

outlined in part (2), and in

addition, the dog pin (19315)

should be examined for bending

or wear in the area that the pin

contacts the camming surface

of the unloader plate. Refer to

Fig. 3 & 4.

(4) Stop bolt 19673. Check for

bending or breakage. Replace

if necessary.

2. After load testing, thoroughly ex-

amine the exterior hoist parts for

damage. Check hooks for bending

or "opening" caused by incorrectly

loading the hook tip, or jamming the

housing out of line during loading—

replace if bent or opened. For swivel

hook models, inspect bearings for

wear. On all models check all cast-

ings for wear, taking corrective

measures if necessary.

3. Disassemble hoist carefully, refer

to disassembly instructions and

exploded view of hoist components.

Wash all parts in a suitable cleaner,

remove all oxides and foreign mate-

rial. Examine mechanism for dam-

aged or excessively worn parts, refer

to the accompanying photographs

for typical examples. Replace all

parts showing evidence of excessive

wear or indications of damages.

Particular attention should be given

to the following areas:

Procedure

1. Check operation of the hoist thor-

oughly by lifting and lowering a

minimum of 500 lb. (rated load

preferred). Lifting and lowering

operations should be checked by

operating the hoist in the two posi-

tions of operation, that is, using both

downward and upward strokes to

lift and lower the test load.

INSTRUCTIONS FOR SERVICING

THE CHANCE ONE-TON HOIST

FIG. 2

CUT AWAY VIEW OF "STOP" AREA

Pin Wear At Point

of Contact With

Unloader Plate

Inspect For Pin Wear

At Point of Contact

With Unloader Plate

FIG. 3

DAMAGED PAWLS

FIG. 4

CUT AWAY SHOWING PAWL PIN & UNLOAD-

ER PLATE RELATIONSHIP

FIG. 1

PRINCIPLE "STOP" AREA OF HANDLE

Housing

"Stop"

Screw

56163

Severe

Crease

Note

Crushing

Handle "Stop"

Tip of Unloader

Plate

Impact Damage