Page 5

CONNECTING THE HUBBNET™ NETWORK

The NX™ Lighting Control Panel is designed to operate as part of a

NX

Networked Lighting Control system. Once programmed,

the panel will operate independently from a network connection. No software installation is required. However, a network

connection to the Area Controller is required for programming the panel. The programming interface is served from the Area

Controller and is accessible via a standard web browser on any compatible PC or computer.

The

NX

HubbNet

network is Ethernet compatible with the exception that the Cat5

HubbNet

cable carries 24 VDC as an integral

power source for certain

NX

peripheral devices. CAUTION: never plug a

HubbNet

powered network cable directly into a PC or

other Ethernet device. HCS offers accessory devices that allow

HubbNet

to be converted to standard Ethernet or Ethernet to be

converted back to

HubbNet

. Contact HCS Technical Services for additional information.

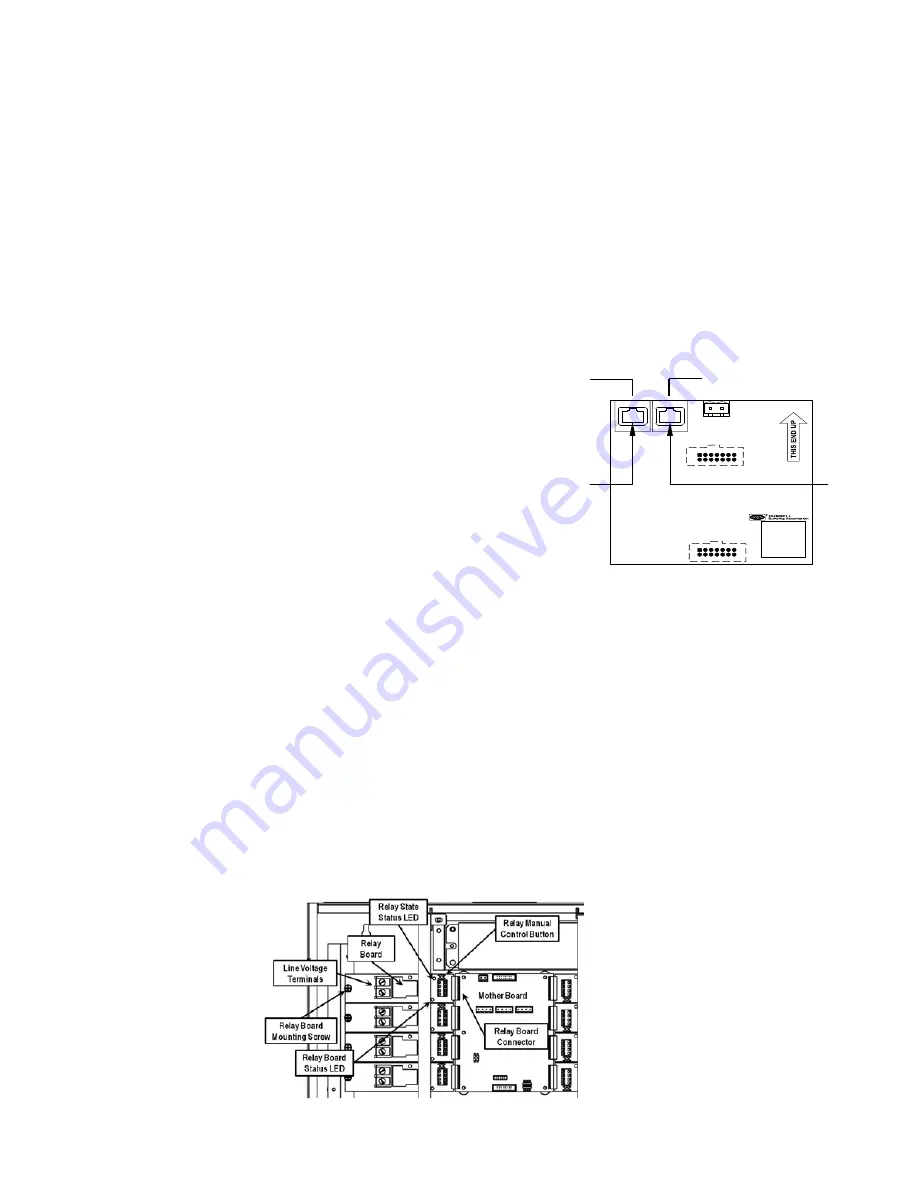

The network interface in the panel is configured to provide an IN and OUT connection point for the

HubbNet

network. This allows

a single daisy chain connection of the panels minimizing the amount of Cat5 wire required to connect the Area Controller to the

network of panels. See

Figure 4

1. Connect the Cat5 cable from the Area Controller into the

Non-Powered RJ-45 connector on the network interface board of the

first panel

2. Connect the Powered RJ-45 connector on the network interface

board of the first panel to the Non-Powered RJ-45 connector in the

next panel

3. Continue to run the network until all panels are connected.

IMPORTANT: rout the network so that there is no more than 100

meters (330 feet) of Cat5 wire between any two panels.

NOTE: Consult the factory if the installation requires a longer wire

run than 100 meters between panels.

4. With the Area Controller and the panels powered, check to be sure there is a green

LED (link light) adjacent to each RJ-45 connector. If the link light is not lit, confirm the installation of the RJ-5 connectors on the

cables using a proper testing device.

CAUTION: Never attempt to splice Cat5 cable. Use only proper industry accepted means to extend or join Cat5 Ethernet network

cable runs.

OPERATING THE PANEL

The Mother board power status LED will show continuous “green”. The Relay board status LED will turn on “green” for approximately

2 seconds and then go off. Push, but do not hold the Relay Manual Control button on each relay card to operate each relay to test

functionality. The Relay State Status LED will turn on “red” when the relay is energized and be off when the relay is un-energized. The

panel is now fully functional and ready for configuration using the web browser interface provided by the Area Controller.

FIGURE 5 - PANEL START-UP CONTROLS

FIGURE 4 - NETWORK INTERFACE

BOARD - IN - OUT

From Area

Controller or

Previous Panel

To Next Panel

Powered Out

Non Powered In