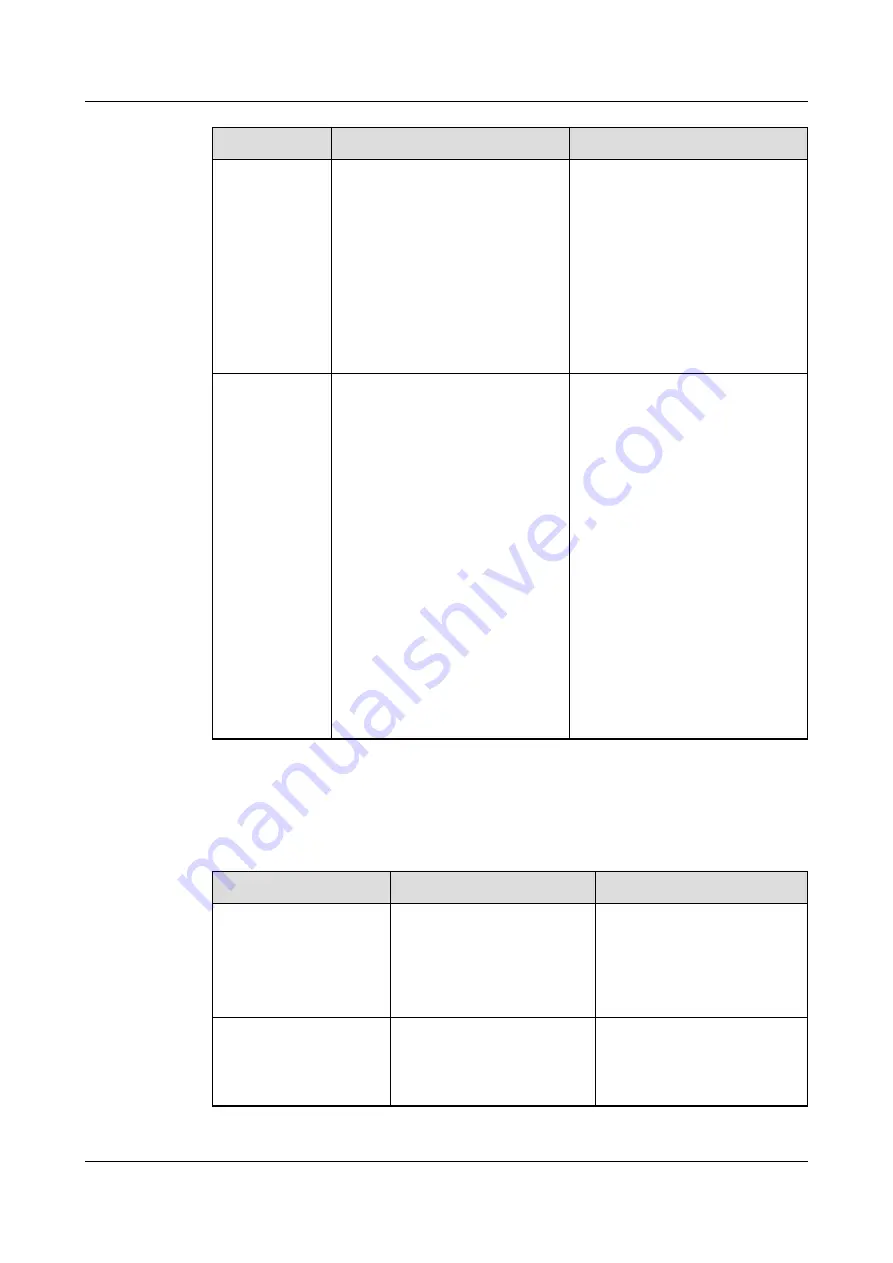

Item

Expected Result

Troubleshooting

Battery

operating

temperature

1. The ambient battery

temperature is 25±5°C.

2. The battery operating

temperature is lower than

battery tempe20°C.

3. Battery charge and

discharge conditions meet

the requirements specified

in the battery

specifications.

1. Identify the cause of an

abnormal battery operating

temperature.

2. If the fault persists, contact

Huawei technical support.

Charge

voltage of

battery string

● Equalized charging voltage:

(2.35 V/cell ±1%) x Single

battery voltage/2 x Number

of batteries in a battery

string

● Float charging voltage:

(2.25 V/cell ±1%) x Single

battery voltage/2 x Number

of batteries in a battery

string

1. If the voltage drop between

the battery string output

terminals and the battery

input terminals at the UPS

side is greater than 1% of

the battery string voltage,

check whether the cable

between the battery string

and the UPS is excessively

long, or the cable diameter

is excessively small.

2. Check whether the

equalized charging voltage

and float charging voltage

are correctly set for the

UPS.

3. If the fault persists, contact

Huawei technical support.

9.2.3 Quarterly Maintenance

Table 9-5 Quarterly maintenance

Check Item

Expected Result

Troubleshooting

Battery temperature

sensor precision

The deviation between

the detected temperature

and the displayed

temperature must be less

than 3°C.

1. Install the temperature

sensor in the correct

position.

2. Replace the battery

temperature sensor.

Battery management

parameter settings

The settings of battery

management parameters

meet the requirements in

the user manual.

Set parameters correctly.

UPS5000-H-(400 kVA-800 kVA)

User Manual (100 kVA Power Module)

9 Routine Maintenance

Issue 02 (2021-04-22)

Copyright © Huawei Technologies Co., Ltd.

147