UPS5000-E-(25 kVA-125 kVA)-FM

User Manual

4 User Interface

Issue 06 (2019-12-13)

Copyright © Huawei Technologies Co., Ltd.

116

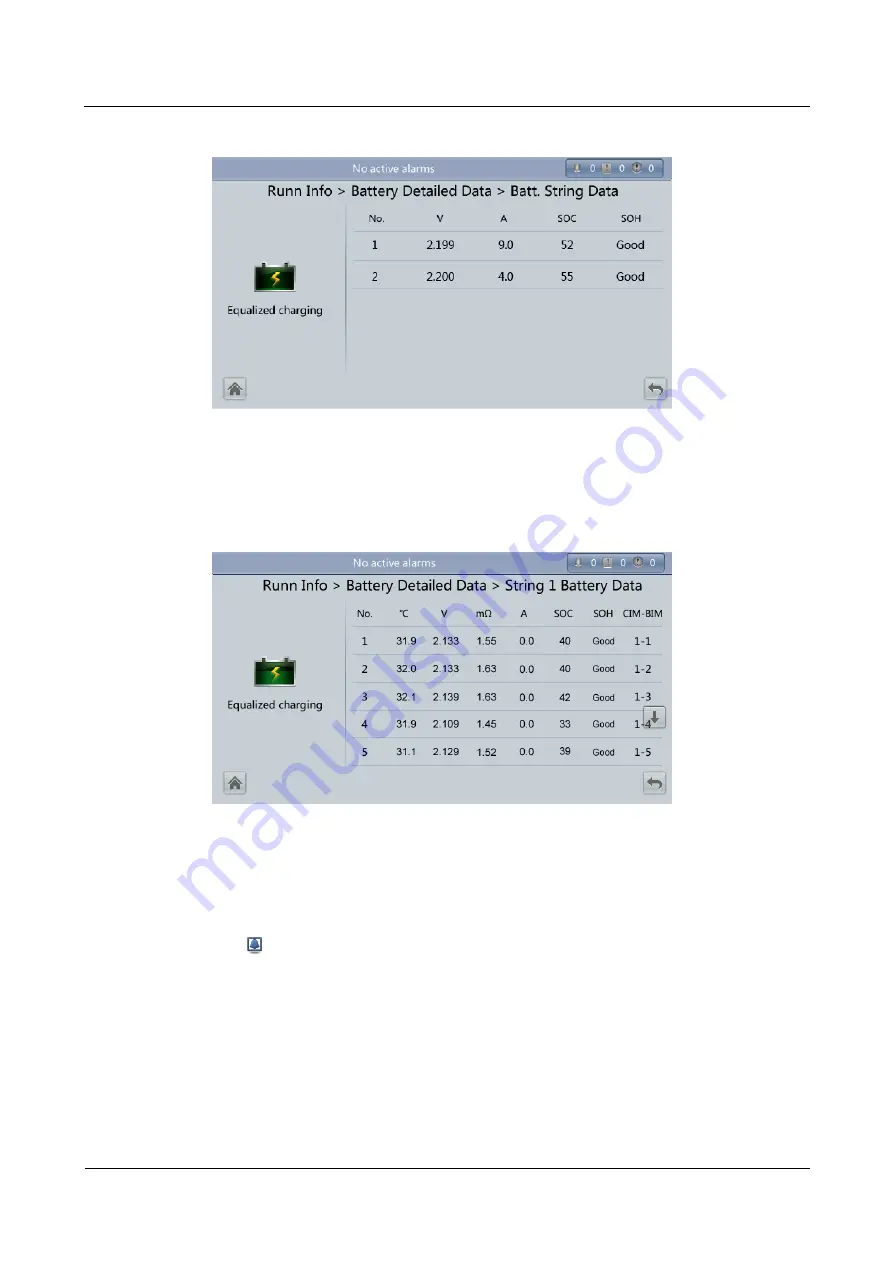

Figure 4-17

Batt. String Data screen

This screen displays the voltages, currents, SOC, and SOH of each battery string.

String N Battery Data

screen.

Figure 4-18

String N Battery Data screen

This screen displays the temperature, voltage, internal resistance, current, SOC, and SOH of a

single battery in the battery string, and the mapping between the CIM and BIM.

4.1.2.3 Alarms Screen

Tap

on the

System Info

screen to enter the

Alarms

screen.