TP48200A-HX09A2, TBC300A-TCA2 Outdoor Power

System

User Manual

C Associations between Alarms and Dry Contacts on the

UIM

Issue 02 (2019-02-26)

Copyright © Huawei Technologies Co., Ltd.

90

C

Associations between Alarms and Dry

Contacts on the UIM

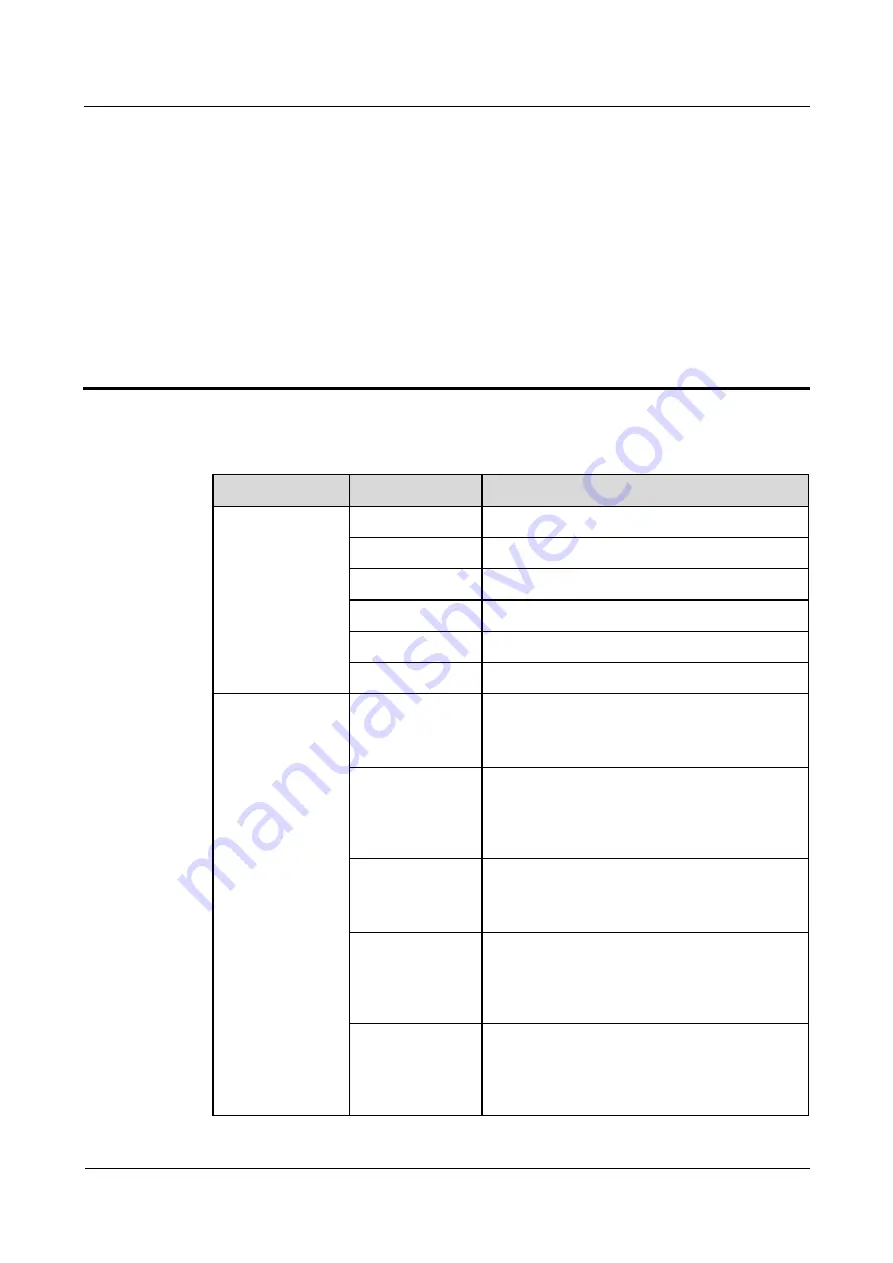

Table C-1

Associations between alarms and dry contacts

Port Type

Silk Screen

Associated Alarm

Dry contact input

DIN1

Dry contact input 1

DIN2

Dry contact input 2

DIN3

Dry contact input 3

DIN4

Dry contact input 4

DIN5

Dry contact input 5

DIN6

Dry contact input 6

Dry contact output

ALM1

Reports alarms for mains faults.

Default mode (Close: alarm; Open: normal) can

be modified as required.

ALM2

Reports alarms for DC output overvoltage or

undervoltage.

Default mode (Close: alarm; Open: normal) can

be modified as required.

ALM3

Reports alarms for module faults.

Default mode (Close: alarm; Open: normal) can

be modified as required.

ALM4

Reports alarms for AC surge protective device

(SPD) faults or DC SPD faults.

Default mode (Close: alarm; Open: normal) can

be modified as required.

ALM5

Reports alarms for battery fuse blown, load fuse

blown, and loop disconnection.

Default mode (Close: alarm; Open: normal) can

be modified as required.