SUN2000-(33KTL, 40KTL)-JP

User Manual

4 System Installation

Issue 07 (2019-06-30)

Copyright © Huawei Technologies Co., Ltd.

30

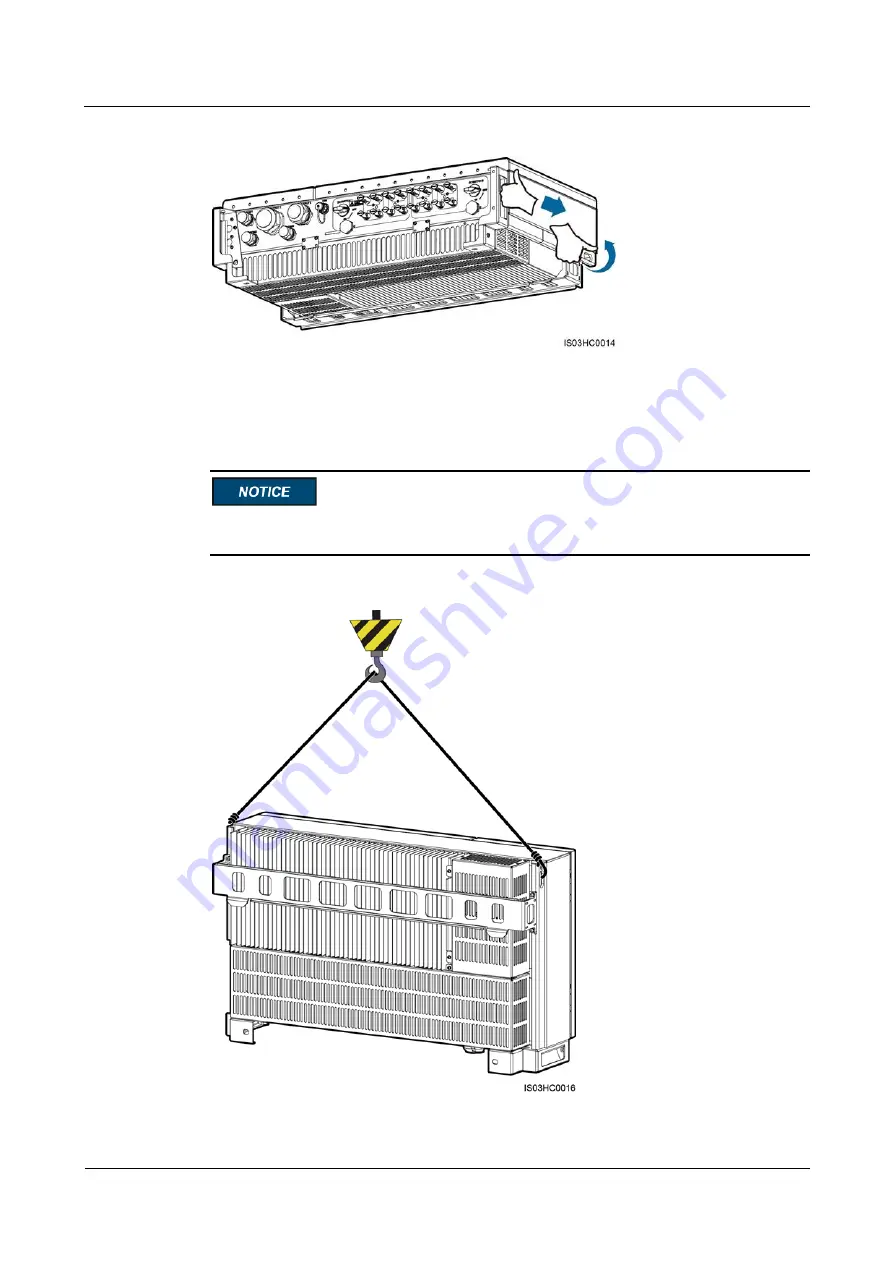

Figure 4-15

Lifting a SUN2000

Step 4

Run a rope that is strong enough to bear the SUN2000 through the lifting eyes and hoist the

SUN2000, as shown in

When hoisting the SUN2000, keep balance to protect the SUN2000 from colliding with the

wall or other objects.

Figure 4-16

Hoisting a SUN2000