NO TICE

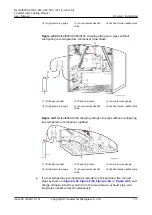

● Exercise caution during welding. It is recommended that you use metal plates

to isolate the welding source from devices in the cabinet to avoid burning the

devices, such as rubber rings and thermal insulation foam.

● Use a rubber hose to connect the nitrogen cylinder which connecting the

reducing valve and the end of the copper pipe, then fill nitrogen at 0.03–0.05

MPa into the copper pipe to avoid internal oxidation, as shown in

● When welding a gas pipe, gently inject nitrogen into the pipe through the

exhaust pipe needle valve.

● When welding a liquid pipe, gently inject nitrogen into the pipe through the

liquid pipe needle valve.

Figure 4-61 Welding pipes

Step 2 (Applicable to downflow units) Cut a cross in the rubber ring using a utility knife

and route the pipe wrapped with the thermal insulation foam through the hole.

NO TICE

Ensure that the rubber ring is not disconnected. If the rubber ring is disconnected

or damaged, seal the gaps around the pipes with mastic cement or thermal

insulation foam.

Step 3 Connect the gas and liquid pipes to the gas and liquid pipes of the outdoor unit

respectively.

Step 4 Wrap the thermal insulation foam.

----End

Side Pipe Routing

Step 1 Remove the plugs from the bottom refrigerant pipe using a welding torque.

NetCol8000-A(045, 055, 060, 090, 120) In-room Air

Cooled Smart Cooling Product

User Manual

4 System Installation

Issue 05 (2020-10-10)

Copyright © Huawei Technologies Co., Ltd.

103