Hook

Hook

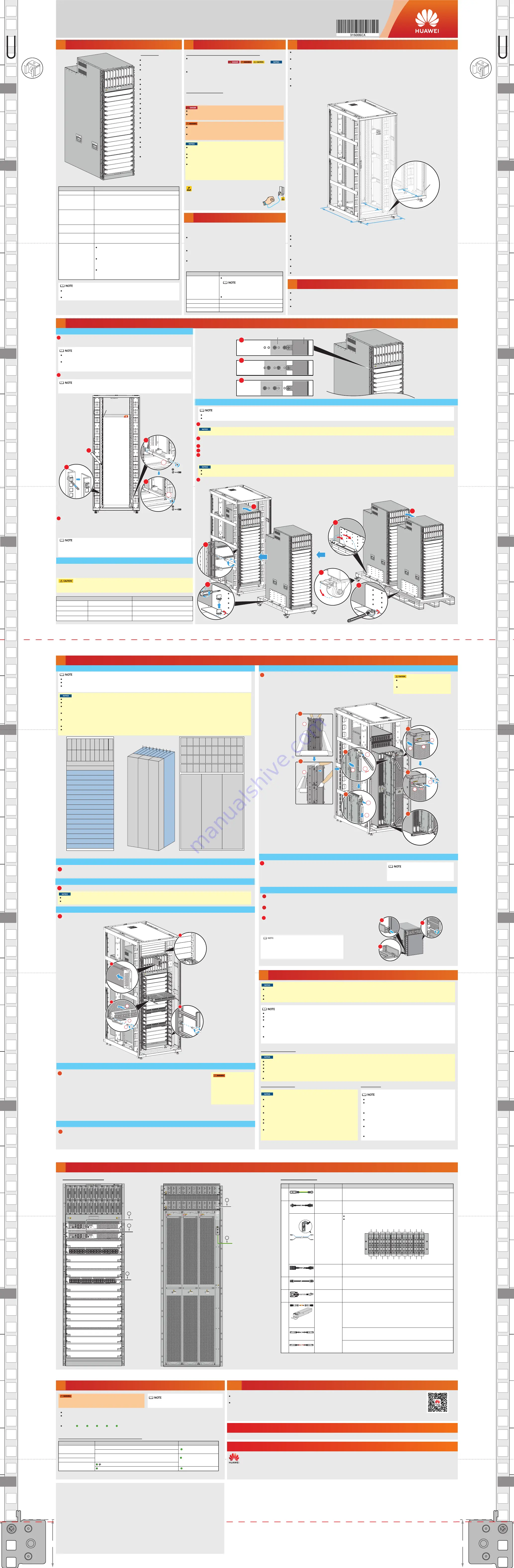

CloudEngine 16816

mounting hole 1

CloudEngine 16816

mounting hole 2

CloudEngine 16816

mounting hole 3

CloudEngine 16816

mounting hole 4

CloudEngine 16816

mounting hole 5

CloudEngine 16816

mounting hole 6

CloudEngine 16816

mounting hole 7

CloudEngine 16816

mounting hole 8

CloudEngine 16816

mounting hole 9

CloudEngine 16816

mounting hole 10

CloudEngine 16816

mounting hole 11

CloudEngine 16816

mounting hole 12

CloudEngine 16816

mounting hole 13

CloudEngine 16816

mounting hole 14

CloudEngine 16816

mounting hole 15

CloudEngine 16816

mounting hole 16

CloudEngine 16816

mounting hole 17

CloudEngine 16816

mounting hole 18

CloudEngine 16816

guide rail

CloudEngine 16816

guide rail

1U

1U

F/L

F/R

Part 2

Part 1

Part 2

Part 1

Obtaining Product Documentation and Technical Support

10

Place this edge at the bottom of the cabinet/rack.

Open Source Software Notice

Powering On the Chassis

9

Before performing a power-on check, ensure that power switches on

the external power supply system and the switch are turned off.

Indicator status when the switch is working properly

Verify that the input voltage is within the operating voltage range for the switch.

Turn on the power switches on the external power supply system and then the two power switches on the chassis to power it on. The

chassis can be powered on when one power switch is turned on. However, to ensure reliable system power supply, both power switches

must be in ON state when the chassis is running.

When the indicators on the chassis header are in normal state (steady green), check the

indicators on other modules.

PWR

MPU

LPU

SFU

FAN

Module

Indicator

Status

Power module

MPU

LPU

Fan module

Steady green

Steady green

Slow blinking green

Input (green)

Output (green)

RUN/ALM (red, green, yellow)

(red, green, yellow)

SFU (red, green, yellow)

For more information about indicators, see the

.

Connecting Cables

8

Cable connection diagram

Cable connection table

To prevent the fan tray from falling

down, hold both handles while

removing it.

为了避免机盒跌落,搬出之前请双

手紧握把手。

To prevent the fan tray from falling

down, hold both handles while

removing it.

为了避免机盒跌落,搬出之前请双

手紧握把手。

To prevent the fan tray from falling

down, hold both handles while

removing it.

为了避免机盒跌落,搬出之前请双

手紧握把手。

CloudEngine16800

PM11

1

PM12

2

PM13

3

PM14

4

PM15

5

PM16

6

PM17

7

PM18

8

PM19

9

PM20

10

INPU

T

OU

TPU

T

A

LA

R

M

INPU

T

OU

TPU

T

A

LA

R

M

INPU

T

OU

TPU

T

A

LA

R

M

INPU

T

OU

TPU

T

A

LA

R

M

INPU

T

OU

TPU

T

A

LA

R

M

INPU

T

OU

TPU

T

A

LA

R

M

INPU

T

OU

TPU

T

A

LA

R

M

INPU

T

OU

TPU

T

A

LA

R

M

INPU

T

OU

TPU

T

A

LA

R

M

INPU

T

OU

TPU

T

A

LA

R

M

INPU

T

OU

TPU

T

A

LA

R

M

INPU

T

OU

TPU

T

A

LA

R

M

INPU

T

OU

TPU

T

A

LA

R

M

INPU

T

OU

TPU

T

A

LA

R

M

INPU

T

OU

TPU

T

A

LA

R

M

INPU

T

OU

TPU

T

A

LA

R

M

INPU

T

OU

TPU

T

A

LA

R

M

INPU

T

OU

TPU

T

A

LA

R

M

INPU

T

OU

TPU

T

A

LA

R

M

INPU

T

OU

TPU

T

A

LA

R

M

Switch1

Switch2

Open

0

1

10

11

12

13

22

23

24

25

34

35

RUN/ALM

1

2

3

4

0

1

10

11

12

13

22

23

24

25

34

35

36

37

46

47

RUN/ALM

FAN

SFU

LPU

MPU

PWR

FRONT

REAR

CLK/TEST

CONSOLE

TOD

GE1

SFP+1

CLK

ETH

GE0

SFP+0

HP-GE

RSTET

RUN/ALM

ACT

M/S

CLK/TEST

CONSOLE

TOD

GE1

SFP+1

CLK

ETH

GE0

SFP+0

HP-GE

RSTET

RUN/ALM

ACT

M/S

Ground cable, connected to

a cabinet ground point

1

2

AC power cable, connected to

a power distribution box

Console cable,

connected to an

operation terminal

Ethernet cable,

connected to an

operation terminal

3

4

Signal cable

(not Ethernet cable),

connected to a router

or switch

5

Connecting Cables

8

Route cables

Route cables out of the chassis from the left and right sides symmetrically.

Pull the plastic parts of the cable management frames out a little, route

cables through the cable management frames, and then push the plastic

parts in place.

Bundle power cables at 250-mm intervals and use cable ties to fix them

on the rack.

Power cables and ground cables must be more than 30 mm away from

signal cables.

Use cable ties to bundle Ethernet cables and high-speed cables to the rack

at 250-mm intervals. Use binding straps to bundle optical fibers and AOC

cables at 250-mm intervals and use cable ties to fix them on the rack.

Arrange the fibers neatly and route them along the cable tray.

Connect power cables

Before connecting power cables, ensure that both power switches on the chassis are turned off.

To ensure that the connectors and maximum current of power cables meet requirements of the switch, use the power cables delivered with the switch.

The power sockets on the power distribution unit at the rear of chassis and the power modules at the front of chassis have a one-to-one mapping.

Follow the power redundancy principle when connecting power cables. Do not insert all the power cables to the sockets connected to the same circuit breaker on

the PDU.

Do not bend OT terminals to 90 degrees onsite.

For details about cables and optical modules, see the

.

The ground point of CloudEngine 16800 series switches is located at the rear of the chassis and supports a ground cable with a two-hole OT terminal.

If only one power source is available in the equipment room, connect all PMs to power source A (terminal blocks or power sockets A1 to A20) or power source B

(terminal blocks or power sockets B1 to B20).

When both power sources A and B are available:

In AC or high-voltage DC scenarios, power source A is used by default. If power source A is faulty, the system automatically switches to power source B.

In DC scenarios, if the two power sources have different voltages, the power source with a higher voltage provides a higher current.

Requirements for the power distribution of a customer's cabinet: The output power of power sources A and B must be greater than the maximum input power of

the switch

When routing power cables, Ethernet cables, and high-speed cables, route low-voltage cables separately from high-voltage cables. Metallic strength members and

metal armor used in optical fibers must not be routed into the cabinet/rack.

Connect the ground cable before connecting other cables.

When using a ground cable with a one-hole OT terminal, route the ground cable properly to prevent it from hindering installation and removal of fan modules.

Connect signal cables

Cover idle optical ports and optical modules with dust plugs and cover idle

optical fibers with dust caps.

A fiber's bend radius must be 20 times larger than the fiber's diameter, and is

generally greater than or equal to 40 mm.

Overbending of high-speed cables may damage wires in the cables. The bend

radius of high-speed cables must be larger than their minimum bend radius.

The bend radius of AOC cables must be no less than 30 mm.

Do not bundle fibers too tightly. Ensure that you can easily remove a single

fiber from the bundle.

Use an Ethernet cable tester to test conductivity of Ethernet cables before

bundling them.

7.2 Install Cable Management Frames

1

7.4 Install 1U Filler Panels

Insert the positioning pins of a cable management frame into mounting holes on the chassis, slide the cable management frame up and down to fit the

positioning pins in the recess of the mounting holes, and tighten the captive screws on the cable management frame. Tighten the captive screws with a torque

of 0.54 N·m.

7.7 Install Fan Modules

SFU slots SFU1, SFU2, and SFU9 cannot be used.

Vacant slots must be inserted with fifiller panels.

Before installing a card, power module, or fan module, remove filler panels at the rear of the switch and from the corresponding slot. Keep the removed filler

panels in an appropriate place for future use.

Slots of a CloudEngine 16816 (rear)

FAN1

FAN2

FAN3

SFU1 SFU2 SFU3 SFU4 SFU5 SFU6

SFU7 SFU8 SFU9

Socket

A20

Socket

A19

Socket

A18

Socket

A17

Socket

A16

Socket

A15

Socket

A14

Socket

A13

Socket

A12

Socket

A11

FAN1

FAN2

FAN3

Socket

B20

Socket

B19

Socket

B18

Socket

B17

Socket

B16

Socket

B15

Socket

B14

Socket

B13

Socket

B12

Socket

B11

Socket

A10

Socket

A9

Socket

A8

Socket

A7

Socket

A6

Socket

A5

Socket

A4

Socket

A3

Socket

A2

Socket

A1

Socket

B10

Socket

B9

Socket

B8

Socket

B7

Socket

B6

Socket

B5

Socket

B4

Socket

B3

Socket

B2

Socket

B1

Slots of a CloudEngine 16816 (front)

Slot 18 - MPU

Slot 17 - MPU

PM11

PM12

PM13

PM17

PM18

PM19

PM14

PM15

PM16

PM20

PM1

PM2

PM3

PM7

PM8

PM9

PM4

PM5

PM6

PM10

Slot 16 - MPU

Slot 15 - MPU

Slot 14 - MPU

Slot 13 - MPU

Slot 12 - MPU

Slot 11 - MPU

Slot 10 - MPU

Slot 9 - MPU

Slot 8 - MPU

Slot 7 - MPU

Slot 6 - MPU

Slot 5 - MPU

Slot 4 - MPU

Slot 3 - MPU

Slot 2 - MPU

Slot 1 - MPU

Do not remove filler panels from vacant slots to ensure good electromagnetic shielding, heat dissipation, and dustproof performance.

Before the installation, ensure that the chassis and modules are free from water drips.

When installing a card, ensure that ejector levers of the card are at the bottom to avoid incorrect card installation. Incorrect card installation will damage the

connector at the rear of the card.

When installing a card, gently push the card along the guide rails, and be careful not to crash the card connector. Distorted card connector will cause pins on the

opposite card connector or backplane connector to bend.

If the connector of a card has collided with the slot or other object, ask Huawei professionals whether the card can still be installed. Installing a card with distorted

connector will cause damages to the switch.

Do not install an MPU in an LPU slot or install an LPU in an MPU slot.

Install two MPUs of the same type into the active and standby MPU slots on a device. Only P series and SAN series of LPUs or SFUs can be installed on the same

device. Otherwise, the device may be damaged.

Installing Modules

7

7.1 Slot Description

6.3 Install the Chassis in the Cabinet/Rack

Tighten the captive screws on mounting brackets.

1

3

6

If MPUs, LPUs, SFUs, power modules, and fan modules have been installed on the switch, you are advised to remove them before installing the switch in the cabinet/rack.

If a power distribution box needs to be installed in the same cabinet/rack as the switch, install the switch first, and then the power distribution box.

Do not impose loads on the interior bottom (if any) of the cabinet/rack during the installation.

Protect your personal safety when dragging the metal handles at the rear of chassis.

5

2

4

Installing the Chassis

6

6.1 Install Floating Nuts and Guide Rails

When marking the positions of floating nuts and guide rails, keep the bottom edge of the installation

template on the first scale tick counted from the bottom.

Positions of mounting brackets only need to be marked on the front mounting rails, whereas positions of

expandable guide rails must be marked on both the front and rear mounting rails. Keep the mounting holes

on the front and rear mounting rails on the same horizontal plane.

(Two persons) Align mounting holes on the installation template with mounting holes on the mounting rails,

and fix the installation template on the mounting rails. Mark positions of the mounting brackets and

expandable guide rails. Then remove the installation template.

Install floating nuts in the marked mounting holes.

1

2

3

Power Distribution Requirements

5

If CloudEngine 16800 series switches use AC or high-voltage DC power supply, the PDU installed in the cabinet must provide at least

16 A of rated output current on each line. Replace the PDU if this requirement cannot be met.

If CloudEngine 16800 series switches use DC power supply, the power supply device must provide at least 58.5 A of rated output

current on each line. Replace the power supply device if this requirement cannot be met.

CloudEngine 16800 series switches must be reliably grounded. Circuit breakers with the current leakage protection function are not

recommended for the switches.

Cabinet Requirements

4

The Huawei A812 cabinet is recommended. To support the chassis in the cabinet/rack, you can use Huawei expandable guide rails

(expandable between 500 mm and 850 mm) or separately purchased guide rails or tray with sufficient load bearing capacity.

A 800 mm wide and 1200 mm deep cabinet/rack is recommended. It is recommended that the distance (distance A in the figure) between

front mounting tails and the outer side of the front door is in the range from 165 mm to 175 mm, and the distance (distance B in the figure)

between front and rear mounting rails is in the range from 650 mm to 750 mm.

The cabinet or rack to be adopted must have enough vertical space for device installation:

CloudEngine 16816 DC chassis: ≥ 37U

CloudEngine 16816 AC & high-voltage DC chassis: ≥ 35U

For chassis heat dissipation and convenient maintenance, leave at least 1000 mm of clearance at the front and rear of the switch. Do not

install the switch against a wall.

If the switch is installed in a 600 mm wide cabinet/rack, do not install a PDU directly facing the switch. Otherwise, the installation and

removal of fan modules are affected. When installing a PDU, ensure that the PDU and the switch are installed at different heights in the

cabinet/rack.

The cabinet must have reliable ground terminals for equipment grounding.

Cables must be routed out symmetrically from the left and right sides of the cabinet. An 800 mm wide cabinet can provide sufficient

spacing for cabling.

If you use AC power modules and AC power cables delivered from Huawei, ensure that an AC power source is available within 3 m

(cable distance) away from the power distribution unit (PDU) of the switch. If you use DC power modules, determine the distance from

the power distribution cabinet to the PDU of the switch (cable distance) according to site survey results. DC cables delivered from

Huawei are 20 m long by default.

The cabinet must have sufficient load bearing capacity to support all the devices in it. The minimum load bearing capacity for a single

chassis is 859 kg.

The cabinet must meet the requirements for front-to-back airflow, and the front and rear doors must have a porosity rate of more than

55%.

If necessary, use an earthquake-proof cabinet complying with GR63 Zone4 or Zone3 standard.

The following factors must also be taken into account when you select a cabinet:

Site Requirements

3

The equipment must be installed in a clean, dry, and well ventilated standard

equipment room where temperature can be controlled within a proper range. The

equipment room must be free from leaking or dripping water, heavy dew, and

humidity.

Take dustproof measures in the equipment room. Dust will cause electrostatic

charges on the chassis and affect connections of metal connectors and joints. This

shortens equipment service life and may cause failures of the switch.

The installation site must be free from acidic, alkaline, or other corrosive gases.

The CloudEngine 16816 switch must be used indoors. To ensure normal operations

and long service life of the switch, the installation site must meet the following

requirements:

The temperature and humidity in the installation site must be within allowed

ranges. (See the table below.)

Item

Temperature

Operating relative humidity

Storage relative humidity

Requirement

Operating temperature: 0°C to 40°C (0 m to 1800 m)

When the altitude is between 1800 m and 5000 m,

the highest operating temperature reduces by 1ºC

every time the altitude increases by 220 m.

5% RH to 85% RH, noncondensing

Storage temperature: -40ºC to +70ºC

5% RH to 95% RH, noncondensing

Operating/Storage altitude

≤ 5000 m

Safety Guidelines

2

Observe all safety regulations and precautions

Before installing, operating, or maintaining the equipment,

wear an ESD wrist strap and insert the other end into the ESD

jack on the chassis or cabinet. Remove conductive objects like

jewelry and watches to prevent damages to the equipment

and cards caused by electrostatic discharge.

ESD protection

Only trained and qualified personnel are allowed to install, operate or maintain the

equipment. Familiarize yourself with all safety precautions before performing any

operation on the equipment.

Operator qualifications

During equipment transport and installation, prevent the equipment from

colliding with objects like doors, walls, or shelves.

Move an unpacked chassis upright. Do not drag it with it lying down.

Do not touch unpainted surfaces of the equipment with wet or contaminated

gloves.

Do not open the ESD bags of cards and modules until they are delivered to the

equipment room. When taking a card out of the ESD bag, do not use the

connector to support the card's weight because this operation will distort the

connector and make the pins on the backplane connector bend.

Do not install or remove the equipment or power cables while power is on.

To ensure equipment and personal safety, ground the equipment before powering

it on.

To ensure personal and equipment safety, observe all the safety precautions on the

equipment and in this document. and

items do not cover all the safety precautions and are only supplementary to the

safety precautions.

Follow all the safety precautions and instructions provided by Huawei. The safety

precautions outlined in this document are only requirements of Huawei and do not

cover general safety regulations. Huawei is not liable for any consequence that

results from violation of regulations pertaining to safe operations or safety codes

pertaining to design, production, and equipment use.

Use multiple persons to move or lift a chassis and take measures to protect

personal safety.

Laser beams will cause eye damage. Do not look into bores of optical modules or

optical fibers without eye protection.

Device Overview

1

This document provides a brief installation guide to help you install the CloudEngine 16816 switch

quickly. For more information, see the .

Figures in this document are for reference only and may be different from actual devices.

Accessories

Item

Height

Weight with MPUs and filler

panels (base configuration)

Weight with 36x100GE LPUs

and SFUs of G series

(full configuration)

Power parameters

CloudEngine 16816

Rated input voltage(DC): -48V DC/-60V

Input voltage range(DC): -40V DC to -72V

Rated input voltage(AC): 220 V, 50 Hz/60 Hz

Input voltage range(AC): 176 V to 290 V, 45 Hz to 65 Hz

Rated input voltage(HVDC): 240V/380V

Input voltage range(HVDC): 188 V to 288 V/260 V to 400 V

Width x Depth (chassis

dimensions, excluding cable

management frames and

mounting brackets)

Width x Depth (max.

dimensions, including cable

management frames and

mounting brackets)

1436 mm (32.3U)

442 mm x 1033 mm

(17.40 in. x 40.67 in. )

483 mm x 1144 mm

(19.02 in. x 45.04 in.)

AC&HVDC: 262.8 kg (579.47 lb)

DC: 273.8 kg (603.73 lb)

AC&HVDC: 569.6 kg (1255.97 lb)

DC: 572.6 kg (1262.58 lb)

(Note: This quick installation guide is also the

Installation Template.

)

CloudEngine 16816 Switch

Quick Installation Guide

Issue: 06

Part Number: 31500BEX

Protect your personal safety when moving the flat cart and pallet. Do not stand in front of the flat cart when it is moving.

18 floating nuts are used to secure the mounting brackets, and 10 floating nuts are used to secure the guide rails

(two for the front end and three for the rear end of each guide rail).

Remove the bolts that fix the chassis.

Place the flat cart at the rear of the chassis and secure it to the pallet. Step on the brakes of all the casters of the flat cart. One person pulls the metal handles at the rear of the chassis to pull the chassis and

adjust the chassis direction, and at least two persons push the chassis horizontally in the front of the chassis, until the chassis cannot move forward.

Loosen the bolts on the flat cart, and then secure the bolts to fix the chassis.

Push the flat cart with the chassis to the front of the cabinet/rack (with the rear of the chassis facing the cabinet/rack). Remove the screws and bolts that fix the chassis on the flat cart.

Align bottom edges at two sides of the chassis with the guide rails and place the chassis onto the guide rails. One person holds the metal handles at the rear of the chassis to drag the chassis and keep the chassis

in the correct direction. At least two persons stand in the front of the cabinet/rack to push the chassis along the guide rails, until the mounting brackets on the chassis are completely attached to the mounting

rails.

Ground cable

AC power cable

DC power cable

Ethernet cable

Console cable

Optical

fiber

High-speed cable

1

2

3

5

4

Select appropriate fibers for optical modules. For more information, see "Optical Fiber" and

"Optical Module" in the

.

Select AC power cables based on the types of power sockets used in your equipment room.

Huawei provides different types of AC power cables to suit different power sockets. For

more information, see "AC Power Cable" in the

.

Chassis ground point

Power socket on the

AC&high-voltage

DC PEM

Terminal block on the

DC PEM

This port connects the switch to an operation terminal or a network management station.

ETH management port

When the switch is powered on for the first time, use this port for onsite configuration.

Console port

Optical port

For more information, see "High-Speed Cable" in the

.

Connect the two-hole OT2-16-8 terminal to the ground point on the switch and connect

the one-hole OT16-6 terminal to the ground point on the cabinet.

1A

1B

2A

2B

When a DC PEM is installed at the rear of the switch, use DC power cables.

One power module at the front of the chassis corresponds to two terminal blocks. For example,

the power module in PM1 slot corresponds to terminal blocks A1 and B1.

AOC cable

For more information, see "AOC Cable" in the

.

High-voltage DC

PDU power cable

For more information, see "High-Voltage DC PDU Power Cable" in the

.

Power socket on the

AC&high-voltage

DC PEM

B10 B9 B8 B7 B6 B5 B4 B3 B2 B1

A10 A9 A8 A7 A6 A5 A4 A3 A2 A1

No.

Item

Remarks

Connect To

Log in to Huawei enterprise technical support website (

https://support.huawei.com/enterprise

), and select a specific product model and version to find

its documentation.

Log in to Huawei enterprise support community (

https://forum.huawei.com/enterprise

) and post your questions in the community.

Huawei Enterprise

Technical Support

You can view the open source software notice by running the

display copyright

command in the user view.

and other Huawei trademarks are trademarks of Huawei Technologies Co., Ltd.

All other trademarks and trade names mentioned in this document are the property of their respective holders.

No part of this document may be reproduced or transmitted in any form or by any means without prior written consent of Huawei Technologies Co., Ltd.

Copyright © Huawei Technologies Co., Ltd. 2020. All rights reserved.

Trademarks and Permissions

Supplier’s Declaration of Conformity (SDoC)

Unique Identifier: trade name: HUAWEI; product name: Switch;

model number: CloudEngine 16800 series switches

Party issuing Supplier’s Declaration of Conformity

Huawei Technologies Co., Ltd.

Bantian, Longgang District,

Shenzhen, 518129, P.R.C

Tel: +86 755 28780808

Responsible Party- U.S. Contact Information

Huawei Technologies USA Inc.

5700 Tennyson Parkway, Suite 500

Plano, Texas 75024

Main: 214-919-6000 / TAC Hotline: 877-448-2934

FCC Compliance Statement ( for products subject to Part 15)

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause

harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired

operation.

Secure the guide rails to the marked positions in the cabinet/rack. Install the guide rails as follows:

a. Adjust the length of the guide rails and place them in marked positions on the mounting rails by the

plate at the front end and hook at the rear end. The bottom edges of the guide rails must be aligned with

scale lines on the mounting rails. Then secure the guide rails with

M6

screws.

b. Use

M6

screws to secure the air baffle to the guide rails, tighten the M6 screws with a torque of 1.96

N·m.

B

1200 mm

800 mm

A

Front

cabinet door

Remove all m

odules to red

uce chassis

weight before

moving or lif

ting the chas

sis.

建议搬抬前

取出所有模

块,以

减轻机箱

重量。

CAUTION

55kg (121

lbs)

Remove all m

odules to redu

ce chassis

weight before

moving or lif

ting the chassi

s.

建议搬抬前

取出所有模

块,以减轻

机箱

重量。

CAUTION

55kg (121

lbs)

SWITCH1

OPEN

SWITCH

2

CloudEng

ine16800

FAN

SFU

LPU

MPU

PWR

FRONT

REAR

(Note: This quick installation guide is also the

Installation Template.)

CloudEngine 16816 Switch

Quick Installation Guide

Issue: 06

Part Number: 31500BEX

2

F/R

3

(x2)

(x3)

M6

a

3

b

M6

MARK

1

Install floating nuts

(Optional) 6.2 Adjusting the Second Half of the Mounting Bracket

When installing the CloudEngine 16816, reserve sufficient space on the top of the CloudEngine 16816 for

power cable routing.

CloudEngine 16816 DC chassis: reserved space ≥ 3U

CloudEngine 16816 AC & high-voltage DC chassis: reserved space ≥ 1U

Remove all m

odules to red

uce chassis

weight before

moving or lif

ting the chas

sis.

建议搬抬前

取出所有模

块,以减轻

机箱

重量。

CAUTION

55kg (121

lbs)

Remove all m

odules to red

uce chassis

weight before

moving or lif

ting the chas

sis.

建议搬抬前

取出所有模

块,以减轻

机箱

重量。

CAUTION

55kg (121

lbs)

SWITCH1

OPEN

SWITCH

2

CloudEngin

e16800

FAN

SFU

LPU

MPU

PWR

FRONT

REAR

PWR

FAN

SFU

MPU

CloudEngi

ne 12800

SWITCH1

OPEN S

WITCH2

CloudEngine16800

FAN

SFU

LPU

MPU

PWR

FRONT

REAR

6

5

Remove all m

odules to red

uce chassis

weight before

moving or lif

ting the chas

sis.

建议搬抬前

取出所有模

块,以减轻

机箱

重量。

CAUTION

55kg (121

lbs)

Remove all m

odules to red

uce chassis

weight before

moving or li

fting the cha

ssis.

建议搬抬前

取出所有模

块,以减轻

机箱

重量。

CAUTION

55kg (121

lbs)

SWITCH1

OPEN

SWITCH

2

CloudEng

ine16800

FAN

SFU

LPU

MPU

PWR

FRONT

REAR

Remove all m

odules to red

uce chassis

weight before

moving or lif

ting the chas

sis.

建议搬抬前

取出所有模

块,以减轻

机箱

重量。

CAUTION

55kg (121

lbs)

Remove all m

odules to red

uce chassis

weight before

moving or li

fting the cha

ssis.

建议搬抬前

取出所有模

块,以减轻

机箱

重量。

CAUTION

55kg (121

lbs)

SWITCH1

OPEN

SWITCH

2

CloudEng

ine16800

FAN

SFU

LPU

MPU

PWR

FRONT

REAR

1

2

Remove all m

odules to red

uce chassis

weight before

moving or lif

ting the chas

sis.

建议搬抬前

取出所有模

块,以减轻

机箱

重量。

CAUTION

55kg (121

lbs)

Remove all m

odules to red

uce chassis

weight before

moving or lif

ting the chas

sis.

建议搬抬前

取出所有模

块,以减轻

机箱

重量。

CAUTION

55kg (121

lbs)

SWITCH1

OPEN

SWITCH

2

CloudEngin

e16800

FAN

SFU

LPU

MPU

PWR

FRONT

REAR

4

CloudEngi

ne16800

FAN

SFU

LPU

MPU

PWR

FRONT

REAR

3

2

Remove all m

odules to red

uce chassis

weight before

moving or lif

ting the chas

sis.

建议搬抬前取

出所有模

块,以

减轻机箱

重量。

CAUTION

55kg (121

lbs)

Remove all m

odules to redu

ce chassis

weight before

moving or lif

ting the chassi

s.

建议搬抬前

取出所有模

块,以减轻

机箱

重量。

CAUTION

55kg (121

lbs)

SWITCH1

OPEN

SWITCH2

CloudEng

ine16800

FAN

SFU

LPU

MPU

PWR

FRONT

REAR

First half of the

mounting bracket

Second half of the

mounting bracket

Remove all modules to reduce chassis

weight before moving or lifting the chassis.

建议搬抬前取出所有模块,以减轻机箱

重量。

CAUTION

55kg (121 lbs)

Remove all modules to reduce chassis

weight before moving or lifting the chassis.

建议搬抬前取出所有模块,以减轻机箱

重量。

CAUTION

55kg (121 lbs)

1

1

2

3

4

5

Remove all modules to reduce chassis

weight before moving or lifting the chassis.

建议搬抬前取出所有模块,以减轻机箱

重量。

CAUTION

55kg (121 lbs)

Remove all modules to reduce chassis

weight before moving or lifting the chassis.

建议搬抬前取出所有模块,以减轻机箱

重量。

CAUTION

55kg (121 lbs)

2

1

2

3

4

5

Remove all modules to reduce chassis

weight before moving or lifting the chassis.

建议搬抬前取出所有模块,以减轻机箱

重量。

CAUTION

55kg (121 lbs)

Remove all modules to reduce chassis

weight before moving or lifting the chassis.

建议搬抬前取出所有模块,以减轻机箱

重量。

CAUTION

55kg (121 lbs)

3

1

2

3

4

5

Hardware Installation and Maintenance Guide

CloudEngine 16800 Hardware Description

CloudEngine 16800 Hardware

Description

CloudEngine 16800

Hardware Description

CloudEngine 16800 Hardware Description

CloudEngine 16800 Hardware Description

CloudEngine 16800 Hardware Description

CloudEngine

16800 Hardware Description

Expandable guide rail

Quick Installation Guide

Floating nut mounting

bar

Serial cable

Fiber binding tape

Bare crimp terminal

Heat shrink tube

AC power cable

Signal cable label

Power cable label

ESD wrist strap

Cable tie

Tweezers (for inserting and

removing optical fibers)

SFU wrench

Cable management frame

Panel screw

Floating nut and

matching screw

SFU wrench storage box

7.3 Install Power Modules

Measure the distance (A) between the front mounting rail and the outer side of the front door, and adjust the

mounting brackets to proper positions according to the mapping between distance A and mounting bracket

installation positions (The first half of the mounting bracket is connected to a cable management frame and

cannot be adjusted).

Distance A

1000mm deep cabinet

150mm

165mm

175mm(recommended)

165mm~175mm

180mm~190mm

190mm~200mm

Default position (callout 1 in the figure)

Position shown in callout 2 in the figure

Position shown in callout 3 in the figure

1100mm to 1200mm deep cabinet

Mounting Bracket Installation Position

-

The first half of the mounting bracket does not need to be adjusted. Therefore, do not uninstall any screw

used to fix the first half.

Gently push a power module into the slot along the guide rails until you hear a click and the power module cannot move forward.

Do not install both DC and AC power modules on the same switch.

When installing a power module, ensure that the indicator on the power module is on the top.

2

Install 1U filler panels in the cabinet/rack. Place the bottom of a filler panel against the top of the chassis.

7.5 Install SFUs

Do not carry an SFU horizontally

by one person because it is

heavy and long. Two persons are

required when moving an SFU

for a long distance. To prevent

personal injury or damage to the

SFU, follow the preceding steps.

Perform the following steps to install an SFU:

a. Remove filler panels at the rear of the switch and from the slot where an SFU will be installed. Hold the top of the SFU

with both hands and stand the SFU upright. Take the SFU out from the ESD bag.

b. Open the handle on the left side of the SFU. Grasp the handle with one hand and the top of the SFU with the other

hand to stabilize the SFU. Another person removes the latches on the SFU.

c. Place the SFU in the slot and gently push the SFU along the guide rails.

d. Take out the wrenches delivered with the SFU and install the wrenches onto the SFU. If you hear a click, the wrenches

have been installed. Grasp the wrenches with both hands, and gently push the SFU until the hooks of the wrenches are

attached to the interior sides of the slot. Close the wrenches until the SFU is in full and secure contact with the chassis.

e. Remove the wrenches. Press and hold down a round button on the SFU with one hand, hold a wrench with the other

hand, and remove the wrench downwards.

7.6 Install Wrench Storage Box of the SFU

First tilt the wrench storage box of the SFU down to the bottom of the chassis, flatten it and attach it to the bottom of the chassis.

Finally tighten the M3 screws for 3 holes, tighten the captive screws with a torque of 0.54 N·m.

Perform the following steps to install a fan module:

a. Press the release buttons on the right side of the two fan module handles.

b. Turn the fan module handles out.

c. Hold the handles with both hands and gently push the fan module into the slot along the guide rails.

d. Press the release buttons on the right side of the fan module handles to fold the handles.

e. Tighten the captive screws on the fan module. Tighten the captive screws with a torque of 0.54 N·m.

Do not stand a fan module upright to avoid

it falling over and causing damage or injury.

To prevent a fan module from falling down,

hold both handles while removing it.

Remove all m

odules to red

uce chassis

weight before

moving or lif

ting the chas

sis.

建议搬抬前

取出所有模

块,以减轻

机箱

重量。

CAUTION

55kg (121

lbs)

Remove all m

odules to red

uce chassis

weight before

moving or lif

ting the chas

sis.

建议搬抬前

取出所有模

块,以减轻

机箱

重量。

CAUTION

55kg (121

lbs)

SFU

SF

U

SF

U

b

c

a

e

d

e-1

e-2

c

d-2

d-1

b

a

Remove all m

odules to red

uce chassis

weight before

moving or lif

ting the chas

sis.

建议搬抬前

取出所有

模块,以

减轻机箱

重量。

CAUTION

55kg (121

lbs)

Remove all m

odules to red

uce chassis

weight before

moving or lif

ting the chass

is.

建议搬抬前

取出所有模

块,以减轻

机箱

重量。

CAUTION

55kg (121

lbs)

SF

U

7.8 Install MPUs and LPUs

7.9 Install Chassis Doors

Components of the chassis door include dedicated cable

management frames. When installing the chassis door

components, you do not need to install the cable management

frames that are delivered with the chassis.

Figures show chassis door installation on the CloudEngine 16808.

1

Install cable management frames on the device. Insert the positioning pins of a cable management frame into mounting holes on the device, insert the

cable management frame horizontally, and tighten the captive screws on the cable management frame.

2

Install upper and lower enclosure frames on the device. Align the upper and lower enclosure frames with mounting holes on the device, insert the upper

and lower enclosure frames horizontally, and tighten the captive screws on the upper and lower enclosure frames.

Install a chassis door on the device.

a. Align the buckles at the bottom of the chassis door with the lower

enclosure frame and insert the buckles.

b. Push the chassis door to the upper enclosure frame until you hear a click

indicating that hooks of the chassis door clasp in the upper enclosure frame.

3

1

2

3

4

0

Remove all m

odules to red

uce chassis

weight before

moving or lif

ting the chas

sis.

建议搬抬前

取出所有模

块,以减轻

机箱

重量。

CAUTION

55kg (121

lbs)

Remove all m

odules to red

uce chassis

weight before

moving or lif

ting the chas

sis.

建议搬抬前

取出所有模

块,以减轻

机箱

重量。

CAUTION

55kg (121

lbs)

PM1

△

PM2

△

PM3

△

PM4

△

PM4

△

△

PM6

△

PM6

△

PM6

△

PM6

△

PM6

SWITCH1

OPEN

SWITCH

2

RSTET

CLK/TEST

CONSOLE

TOD

GE1

SFP+1

CLK

ETH

GE0

SFP+0

HP-GE

RUN(G)/ALM(

R)/OFL(Y)

ACT

M/S

RSTET

CLK/TEST

CONSOLE

TOD

GE1

SFP+1

CLK

ETH

GE0

SFP+0

HP-GE

RUN(G)/ALM

(R)/OFL(Y)

ACT

M/S

FAN

SFU

LPU

MPU

PWR

FRONT

REAR

1

2

3

NOTE

3

3

2

1

1

1

1

3

3

2

1

Installation procedures for MPUs and LPUs are the

same, except that they are installed in different slots.

The procedure describes installation of an LPU.

Perform the following steps to install an LPU:

a. Rotate the ejector levers of the LPU outward, and gently push the LPU into the slot along the

guide rails until the LPU cannot move forward.

b. Close the ejector levers and push them until they cannot move forward.

c. Tighten the captive screws on the card. Tighten the captive screws with a torque of 1.18 N·m.

4

Remove all m

odules to reduc

e chassis

weight before

moving or li

fting the cha

ssis.

建议搬抬前

取出所有模

块,以减轻

机箱

重量。

CAUTION

55kg (121

lbs)

Remove all m

odules to red

uce chassis

weight before

moving or li

fting the cha

ssis.

建议搬抬前取

出所有模块

,以减轻机

箱

重量。

CAUTION

55kg (121

lbs)

SWITCH1

OPEN

SWITCH

2

CloudEng

ine16800

FAN

SFU

LPU

MPU

PWR

FRONT

REAR

1

2

3

4

0

1

2

3

4

0

0

1

PWR

FAN

SFU

MPU

CloudEngine 12800

CloudEngin

e16800

FAN

SFU

LPU

MPU

PWR

FRONT

REAR

0

2

b

c

a

4

3