Huawei AP4030DN

Hardware Installation and Maintenance Guide

2 AP Installation

Issue 02 (2015-05-18)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

15

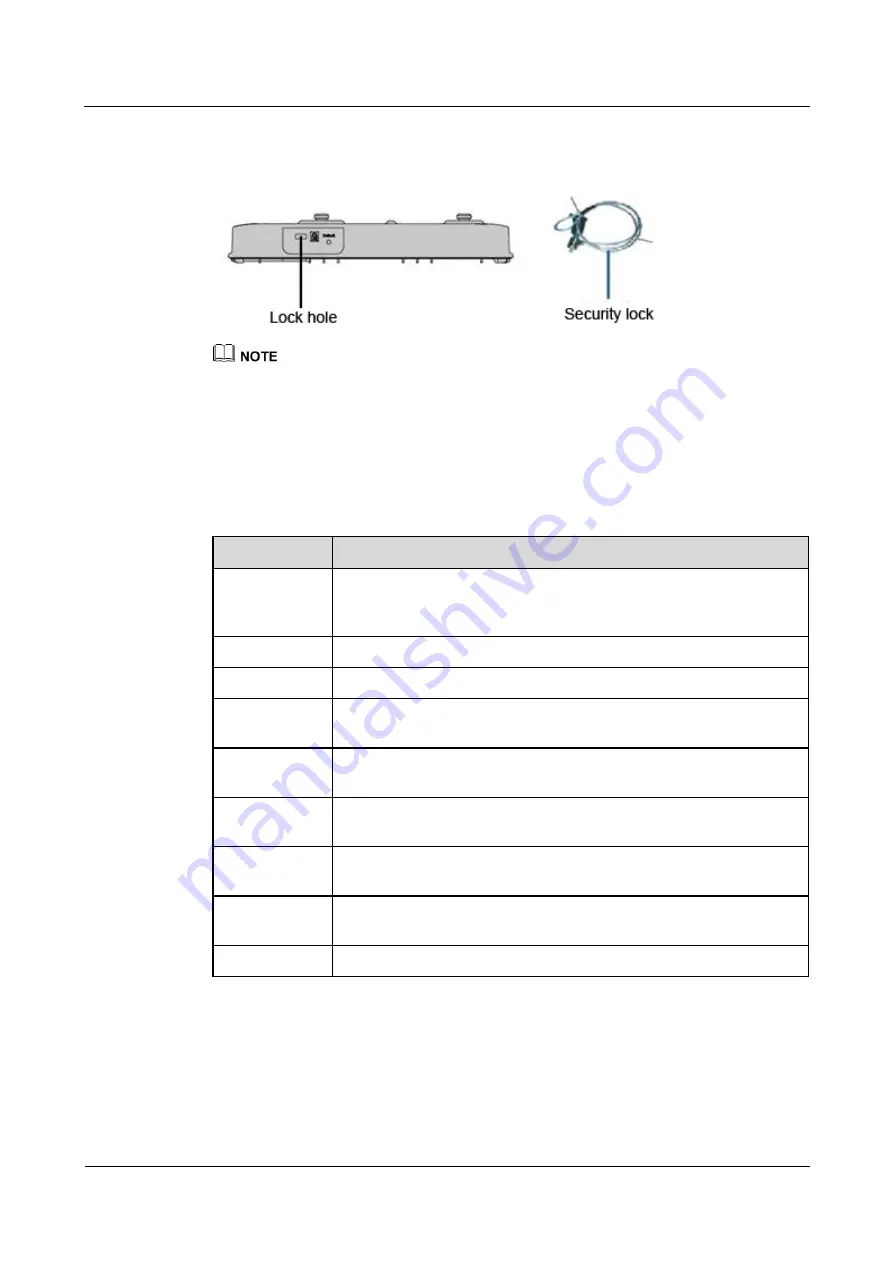

1.

Fasten the cable of the security lock to an immovable object around.

2.

Insert the security lock into the security slot and lock it.

You need to purchase the security lock separately.

2.8 Checking the AP After Installation

shows the items to be checked after AP installation is complete.

Table 2-3

AP installation checklist

No.

Check Item

1

The AP is installed by strictly following the design draft. The

installation position meets space requirements, with maintenance space

reserved.

2

The AP is securely installed.

3

The power cables and PGND cables are intact and not spliced.

4

Terminals of the power cables and PGND cables are welded or cramped

firmly.

5

All power cables or PGND cables are not short-circuited or reversely

connected and must be intact with no damage.

6

The power cables and ground cables are separated from other cables and

bundled separately.

7

The working ground, protection ground, and surge protection ground

share the same group of ground bars.

8

Connectors of signal cables are complete, intact, and tightly connected.

The signal cables are not damaged or broken.

9

Labels on cables, feeders, or jumpers are clear and correct.

2.9 Powering on the AP

You can check the power-on status by observing indicators on the AP. For details, see