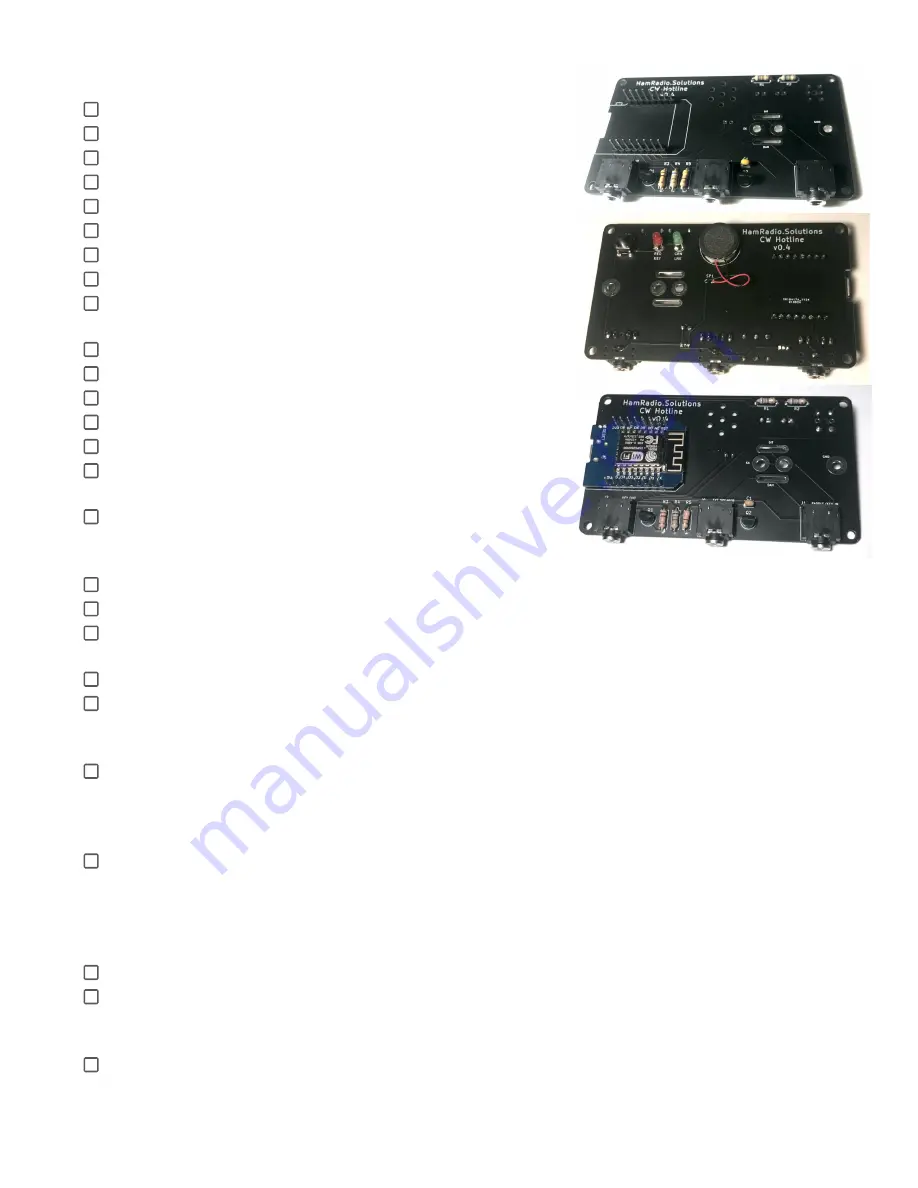

PCB Parts

PCB - CW Hotline Printed Circuit Board

R1, R2, R4 - 680 ohm resistors (blue-grey-brown)

R3 - 10K ohm resistor (brown-black-orange)

R5 - 330 ohm resistor (orange-orange-brown)

C1 - 0.1uf capacitor (marked 104)

Q1, Q2 - 2222A NPN transistors

J1, J2, J6 - 3.5mm stereo TRS jacks

2 1x8 male header posts for ESP8266

ESP8266 in WeMos D1 mini form factor, programmed with

CW Hotline firmware

D1 - green 3MM LED

D2 - red 3MM LED

SW1 - SPST momentary button

1 small speaker

1 small piece foam tape

1 MicroUSB cable

PCB Assembly

Install resistors R1, R2, & R4. For each resistor, bend the

leads near the bulb 90 degrees and parallel and insert into the

PCB. Orientation is not important.

Install resistors R3 & R5 as resistors above.

Install capacitor C1. Orientation is not important.

Install transistors Q1 & Q2. Be sure to match the orientation with the flat side on the silkscreen. Leads

are often very close together so do not let solder contact between any 2 leads.

Install stereo jacks J1, J2, J6. Ensure all jacks are flush with the PCB.

Install 2 1x8 male header posts into PCB. Insert the short sides of the post in the PCB holes. Solder

just one pin each on the other side of the PCB, ensure the pins are perpendicular and flush with the

PCB, temporarily test fit the blue ESP8266 PCB, and then solder the remaining pins.

Insert the blue ESP8266 PCB onto the long sides of the previous header posts, being sure to match the

silk screen orientation, with the reset button nearest the upper left corner. Solder only two diagonally

opposite pins to the hole on the top face of the blue ESP8266 PCB and verify the board is flush. Solder

the remaining pins. Do not trim the remaining exposed posts.

Insert the green LED D1 onto

the other side of the PCB

. The shorter lead, nearest the flat side of the

LED, should go into the square hole.

The LED should not be flush with the PCB

, but instead a 5/32”

or 4mm gap between the PCB and the bottom of the LED. If the case has been drilled, you can fit the

LED and PCB in the case to set the position for the LEDs to slightly protrude. Solder just one lead and

adjust until the spacing is correct, then solder the other lead.

Insert the red LED D2 the same way as D1.

Insert button SW1 on the same side of the PCB as the LEDs. It should only fit one way and the 2

middle pads will not be used.

The button should not be flush with the PCB

, but instead 1/32” or

1mm gap between the PCB and the bottom of the button.

Install the speaker leads into pads marked SP1. If the speaker has a connector on the end of the

leads, remove it and strip the insulation. The red wire should go to the square hole. Solder on the other

side. Use the small square of double sided foam tape to stick the speaker to the PCB above the circle.