Component identification 90

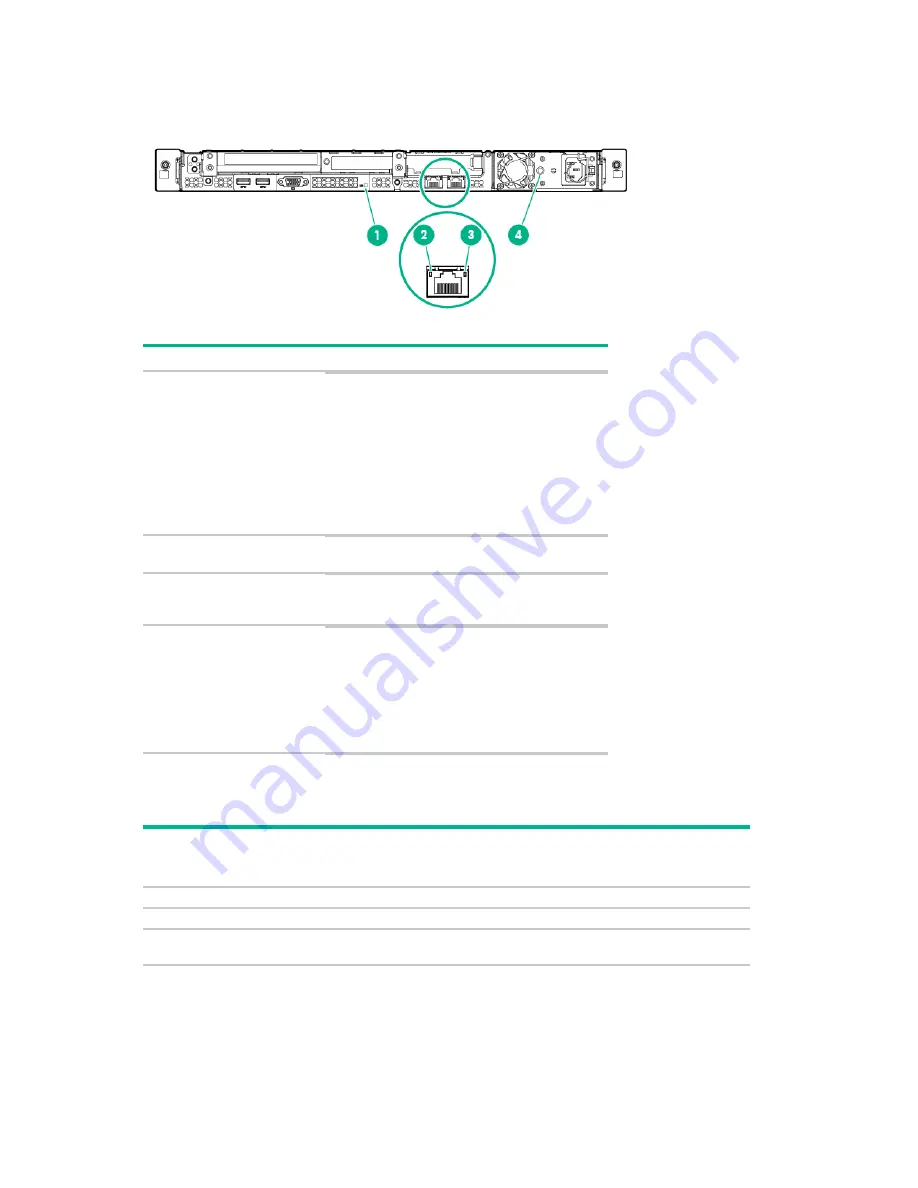

Rear panel LEDs

Item

Description

Status

1

UID LED

Solid blue = Activated

Flashing blue:

•

1 flash per second = Remote management

or firmware upgrade in progress

•

4 flashes per second = iLO manual reboot

sequence initiated

•

8 flashes per second = iLO manual reboot

sequence in progress

Off = Deactivated

2

NIC link LED

Green = Network link

Off = No network link

3

NIC activity LED

Solid green = Link to network

Flashing green = Network active

Off = No network activity

4

Power supply LED Solid green = Normal

Off = One or more of the following conditions

exists:

•

Power is unavailable

•

Power supply failed

•

Power supply is in standby mode

•

Power supply error

PCIe riser board slot definitions

Expansion

Slots

Riser

board

options

Technology Bus

Width

Connector

Width

Form Factor

1

PCIe riser

PCIe 3.0

x16

x16

Low-profile

2

PCIe riser

PCIe 3.0

x8

x8

Low-profile

3

PCIe riser

FlexibleLOM

PCIe 3.0

x8

x8

x8

x8

Full-height/Half-length

FlexibleLOM

Summary of Contents for ProLiant DL60 Gen9

Page 5: ...Contents 5 Documentation feedback 111 Index 112 ...

Page 13: ...Customer self repair 13 ...

Page 14: ...Customer self repair 14 ...

Page 15: ...Customer self repair 15 ...

Page 23: ...Illustrated parts catalog 23 ...

Page 33: ...Removal and replacement procedures 33 o Secondary PCI riser cage o PCI blank ...

Page 95: ...Component identification 95 Fan locations ...

Page 110: ...Acronyms and abbreviations 110 UID unit identification USB universal serial bus ...