Contents 40

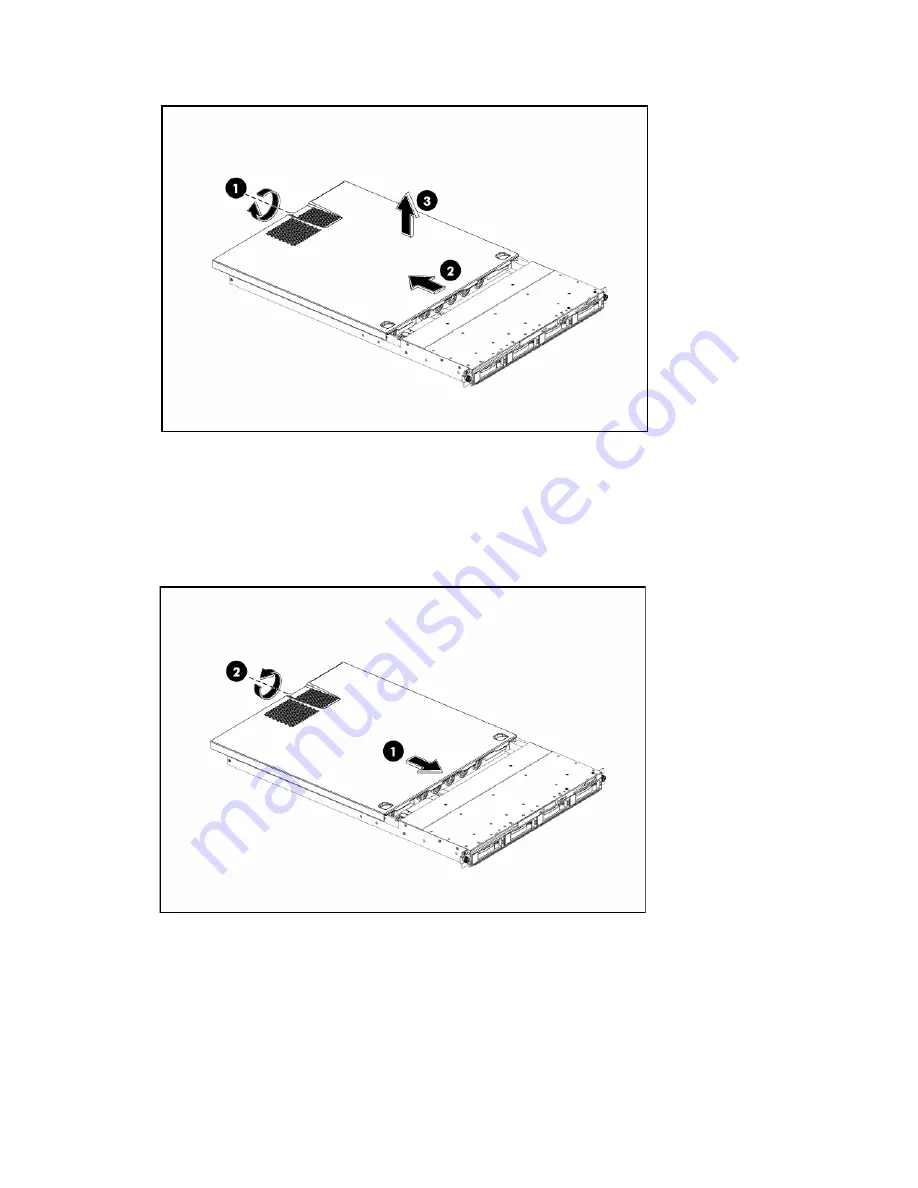

Figure 9

Removing the Top Cover

To reinstall the top cover:

1.

Align the top cover to the chassis and then slide it towards the front panel to position it into

place.

2.

Once the cover is attached to the chassis, tighten the captive screw on the rear panel with a T-15

screwdriver.

Figure 10

Reinstalling the Top Cover

Top middle cover

To remove the top middle cover:

1.

Loosen the four screws (one on each side of the chassis and two on the top middle cover) that

secure the top middle cover to the chassis.

2.

Lift the top middle cover away from the chassis.

Summary of Contents for ProLiant DL160 Generation 6

Page 12: ...Contents 12 ...

Page 13: ...Contents 13 ...

Page 14: ...Contents 14 ...

Page 15: ...Contents 15 ...

Page 19: ...Contents 19 ...

Page 78: ...Contents 78 Figure 70 Installing the system fan ...

Page 86: ...Contents 86 Security menu Figure 76 Security menu of the BIOS setup utility 1 ...